Model 2002 Vacuum Gauge Page 18 of 37

To insure temperature invariance,

Therefore

This requires for any change in sensitivity to be countered by an equal but opposite change in applied

voltage. The temperature compensation is a network of temperature dependent resistive components and

fixed temperature compensation current source compensation, TCR = -TCS.

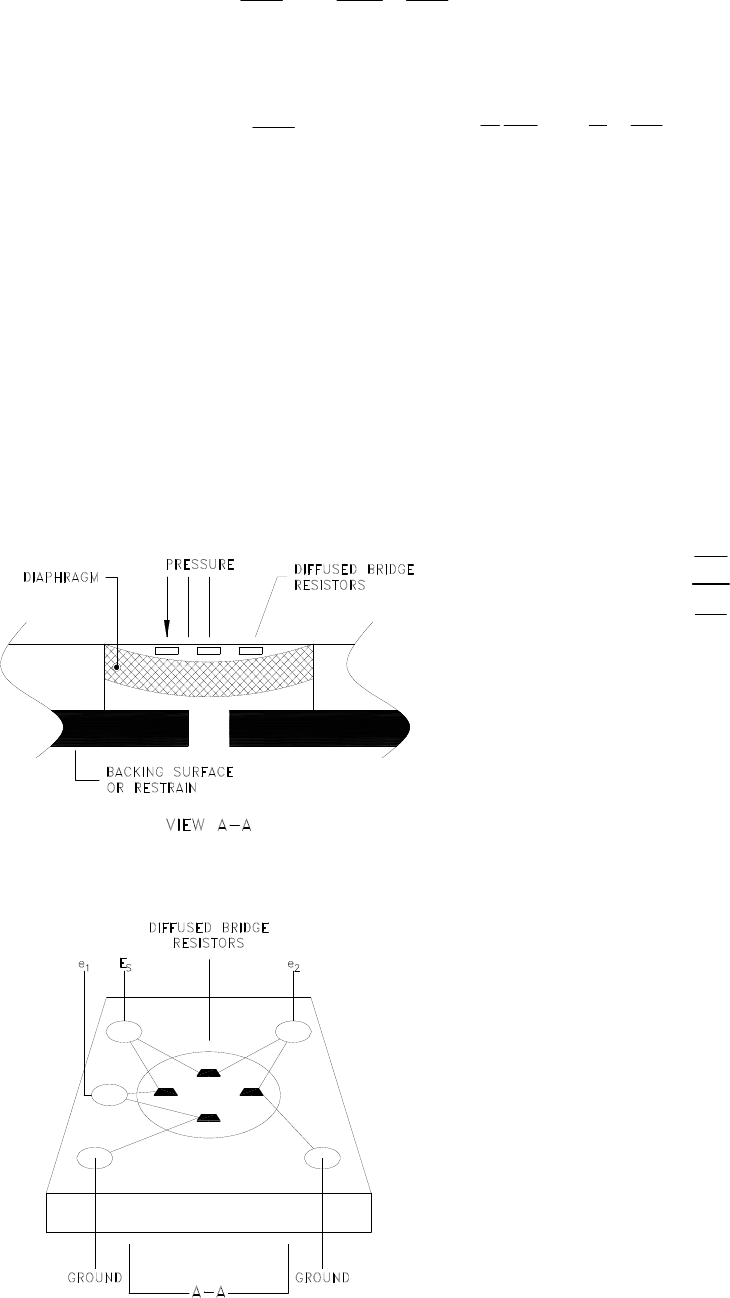

Sensitivity of the sensor is proportional to the sensor factor (K), the strain gauge positioning of the

diaphragm (f) and the diaphragm geometry (q) thus SμKfq. Once the defining geometry of the resistive film

and piezo membrane have been established, the sensor factor is dependent on the crystal orientation of the

membrane material, the doping level and diffusion parameters and the strain gauge geometry. The sensor

factor is essentially the change in resistance for a change in strain or,

Boron ion implanted doped Si matrix resistance elements are employed as shown in figure 5.2.

The die is electro statically bonded

on to a Pyrex substrate in a good

vacuum so that the die cavity is

evacuated; this provides maximum

deflection at atmospheric pressure.

When the sensor is exposed to

vacuum the deflection becomes less

and less as the die cavity pressure

and the vacuum system pressure

equalizes. Eventually the strain in

the membrane due to DP becomes

zero and only the residual strain in

the lattice remains. The bridge

resistive elements are oriented to

give maximum change in bridge

resistance which in turn gives

maximum voltage out for a given

strain.

⎟

⎠

⎞

⎜

⎝

⎛

+=

dT

VdS

dT

SdV

P

dT

dVo

0=

dT

dVo

⎟

⎠

⎞

⎜

⎝

⎛

+−=

dT

dS

SdT

dV

V

11

L

L

R

R

K

Δ

Δ

=