www.tanaka-usa.com 9 custsvc@tanaka-ism.com

Owner’s Manual

TPE-2501,TPE-2510,TPE-270PF/PN,TPE-250PF

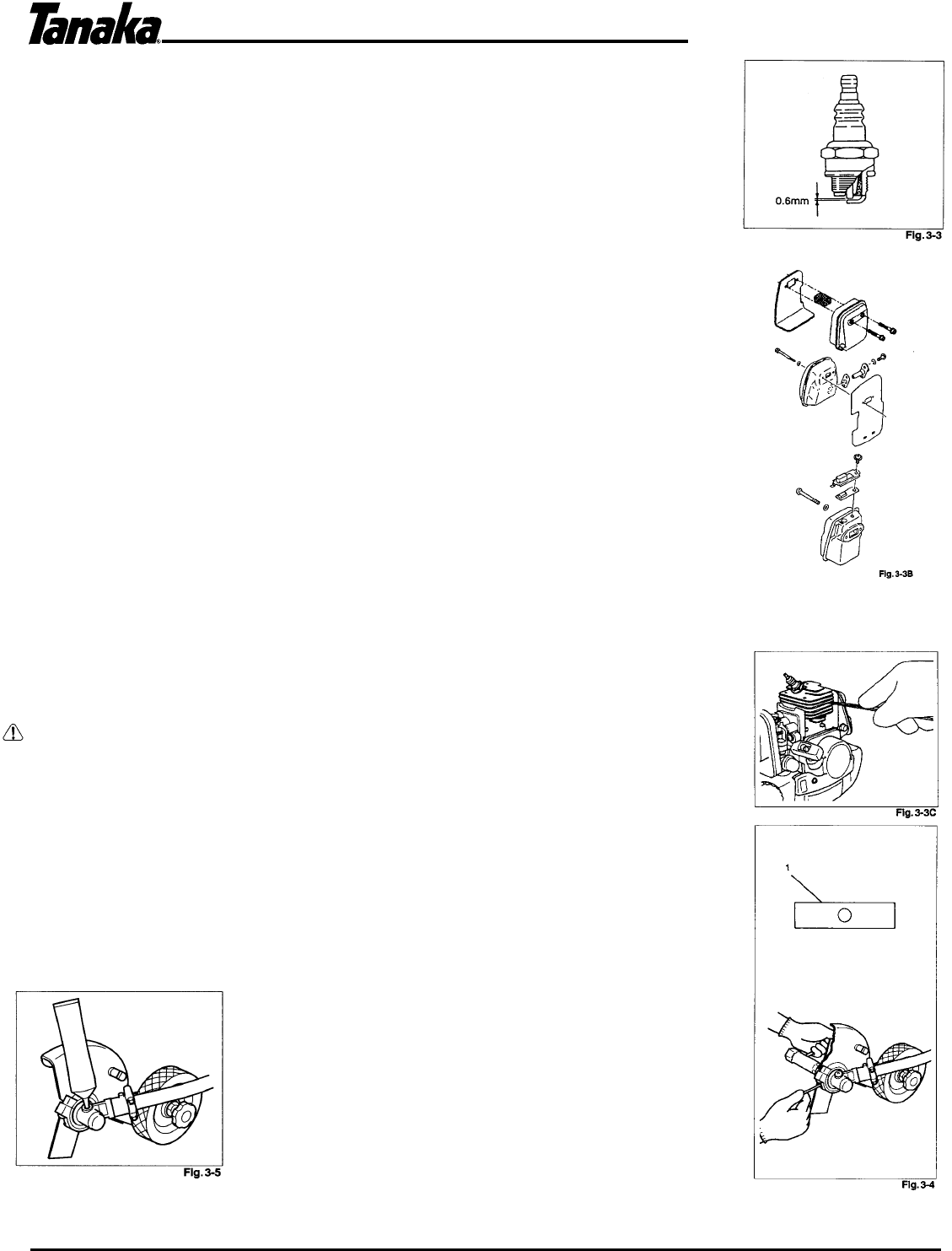

Spark plug (Fig. 3-3)

The spark plug condition is influenced by:

• An incorrect carburetor setting.

• Wrong fuel mixture (too much oil in the gasoline)

• A dirty air filter.

• Hard running conditions (such as cold weather).

These factors cause deposits on the spark plug electrodes, which may result in malfunction

and starting difficulties. If the engine is low on power, difficult to start or runs poorly at idling

speed, always check the spark plug first. If the spark plug is dirty, clean it and check the

electrode gap. Readjust if necessary. The correct gap is 0.6 mm. The spark plug should be

replaced after about 100 operation hours or earlier if the electrodes are badly eroded.

NOTE!

In some areas, local law requires using a resistor spark plug to suppress ignition signals. If this

machine was originally equipped with resistor spark plug, use same type of spark plug for

replacement.

Muffler (Fig. 3-3B)

Remove the muffler and clean out any excess carbon from the exhaust port or muffler inlet

every 100 hours of operation.

Cylinder (Engine cooling) (Fig. 3-3C)

The engine is air cooled, and air must circulate freely around engine and over cooling fins on

cylinder head to prevent overheating.

Every 100 Operating hours, or once a year (more often if conditions require), clean fins and

external surfaces of engine of dust, dirt and oil deposits which can contribute to improper cooling.

NOTE!

Do not operate engine with engine shroud or muffler guard removed as this will cause

overheating and engine damage.

Blade (1) (Fig. 3-4)

WARNING!

• Wear protective gloves when handling or performing maintenance on the blade.

• When replacing blade, purchase one recommended by TANAKA, with a 25.4mm (one

inch) fitting hole.

• Use correct blade for the type of work.

• When replacing blade, use appropriate tools.

•

Discard blades that are bent, warped, cracked, broken or damaged in any way.

Angle transmission (Fig. 3-5)

Check angle transmission or angle gear for grease level about every 50 hours of operation by

removing the grease filler plug on the side of angle transmission.

If no grease can be seen on the flanks of the gears, fill the

transmission with a quality lithium based multipurpose grease up

to 3/4.

Do not completely fill the transmission.

Spark Arrestor

If your unit comes with spark arrestor screen and yet your local

regulation requires use of spark arrestor for prevention against a

possible fire, please attach it to the muffler by removing muffler

protector and other related parts. (The spark arrestor meets the

regulation of SAE J335-SEP90 and CSA CAN3-Z62.1-M77.)