www.tanakapowerequipment.com 4 custsvc@tanaka-ism.com

Owner’s Manual

TCS-3401

3. Assembly procedures

NOTE!

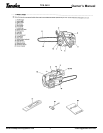

Slightly move the bar back and forth and make sure the chain tension boss (4) fits into the hole (5) in the bar properly.

4. Confirm the direction of saw chain (1) is correct as in the figure, and align the chain on the sprocket. (Fig. 1-3)

5. Guide the chain drive links into the bar groove all around the bar.

6. Install the side case (1) onto the guide bar clamp bolts after inserting it on the alignment/locking tab on the engine case

(2). (Fig. 1 - 1 )

Then fix the clamp nuts temporarily.

WARNING!

Never try to start engine without side case securely fastened.

1. Remove chain bar clamp nuts.

2. Remove the side case (1) while pinching the rear part of the side case (1) .(Fig.1 -1)

Install the spiked bumper (1) (if so equipped) to the unit with the two screws. (Fig. 1 -1 B)

3. Install, the chain bar (1) onto the bolts (2), then push it toward the sprocket (3) as far as it will go. Make sure that the

boss of chain tension adjust bolt (4) fits into the hole of the bar (5). (Fig. 1-2)

CAUTION!

• PROPER TENSION IS EXTREMELY IMPORTANT!

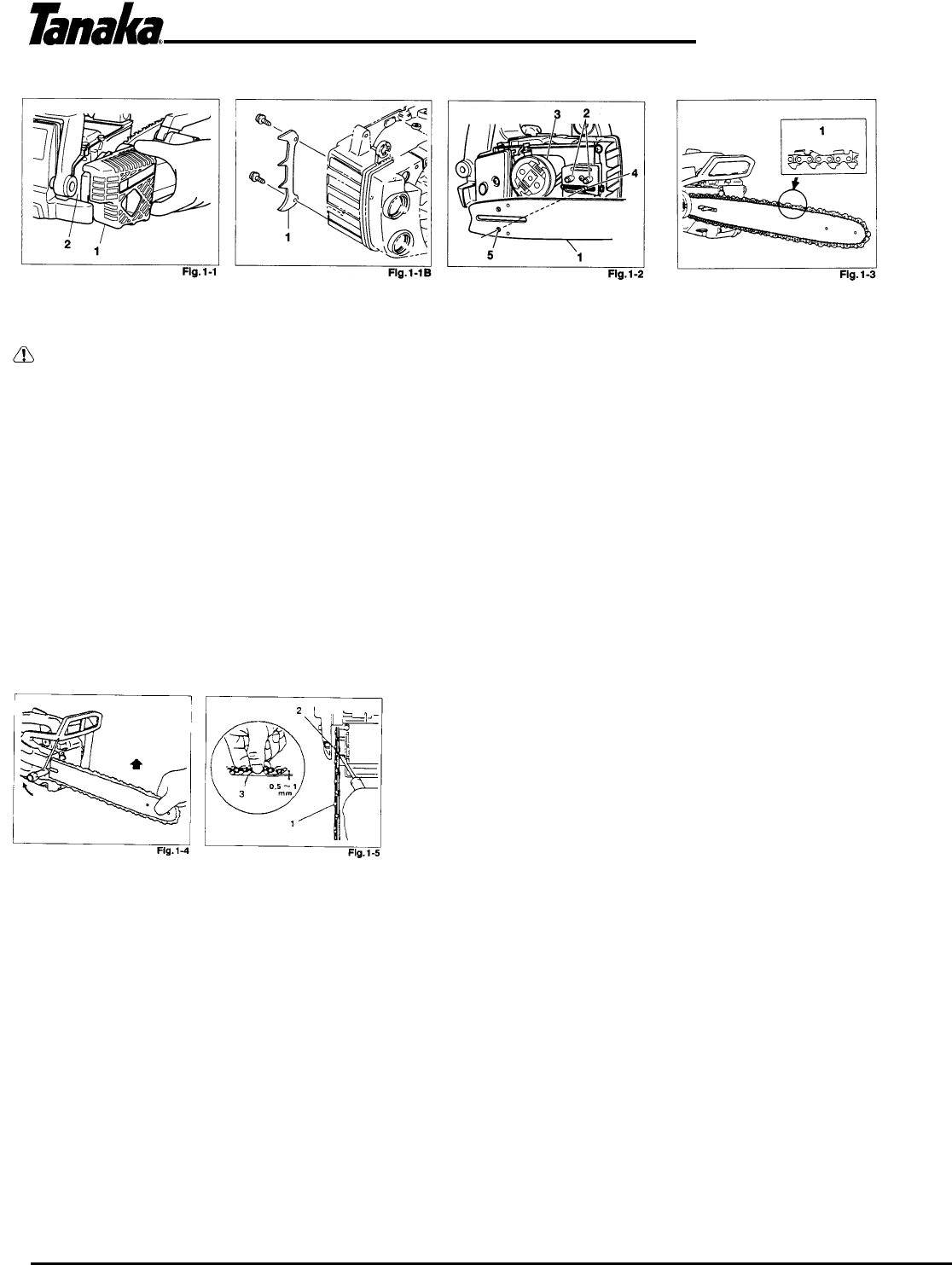

8. Raise the bar end and securely tighten the chain bar clamp nuts with the box wrench. (Fig. 1 -4)

9. A new chain will stretch so adjust the chain after a few cuts and watch chain tension carefully for the first half hour of

cutting.

NOTE!

Check the chain tension frequently for optimum performance and durability.

WARNING!

During operation, hold chain saw firmly with both hands. A single hand operation may cause serious injury.

CAUTION!

• When the chain is excessively tightened, the bar and chain will be damaged rapidly. Conversely, when the chain

is excessively loosened, it may get out of the groove in the bar.

• Always wear gloves when touching the chain.

7. Raise the bar end, and tighten the chain (1) by turning the

tension adjustment bolt (2) clockwise. To check proper tension,

lightly lift up the center of chain and there should be about 0.5-

1.0 mm clearance between bar and edge of drive link (3).

(Fig.1 -4, 5)