SECTION 3

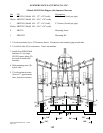

DISK MOUNTING BRACKETS

PN 8H1600 Universal Disk Mounting Bracket,

(13”) Short (w/mounting plate & hardware)

PN 8H1610 Universal Disk Mounting Bracket,

(25”) Long (w/mounting plate & hardware)

PN 8H1602 High-Clearance Disk Mounting Bracket,

(20”) Short (w/mounting plate & hardware)

PN 8H1612 High-Clearance Disk Mounting Bracket,

(29”) Long (w/mounting plate & hardware)

All of the above brackets are designed to be used with Summers M74,

M94, M104 or M106 mounting arms.

When mounting disk brackets directly on disk gangs which run at an

angle, a short and a long bracket are used so harrow sections run square.

When mounting disk brackets on a disk that has a rectangular center

frame, two short brackets are used.

1a. The above fi gure shows two (short) disk mounting brackets. The

universal model on the right is designed to be mounted on top of

the frame with the mounting plate extending up. The high clearance

model on the left is designed to be mounted on top of the frame

with the mounting plate extending down. The high clearance model

is also longer to provide clearance for disk scraper assemblies.

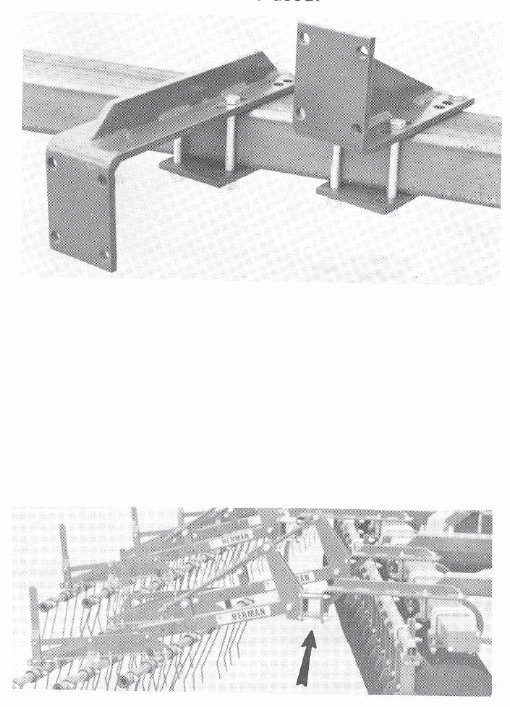

2a. The above fi gure shows a short and a long high clearance disk

bracket used to mount a 7’ section. When carrier arms are spaced 2

teeth apart on high clearance brackets or 3 teeth apart on universal

brackets, the carrier arm bolts directly to the disk mounting bracket

using the four 5/8 x 2” bolts supplied with the disk brackets.

When carrier arms are spaced three teeth apart on high clearance

brackets or four teeth apart on universal brackets, a spacer tube

(see arrow) is used between the carrier arm and the long disk

bracket to keep section square. Order PN 8H1505 for one spacer

tube w/hardware.

19