SECTION 2

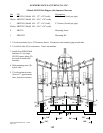

1a. The above 29’ JD1610 chisel plow is shown with a 4 bar mounted

harrow using M74 carrier arms. Two 7’ sections were used in the

center and one 8’ section was used on each wing. An optional

method is to use one 14’ section in the center with 3 carrier arms.

Wing section sizes will vary with the width of the chisel plow.

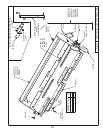

2a. Position frame mounting brackets on the frame as shown above.

All measurements are from bracket center to bracket center. Again

spacing on wing sections will vary with the width of the chisel

plow.

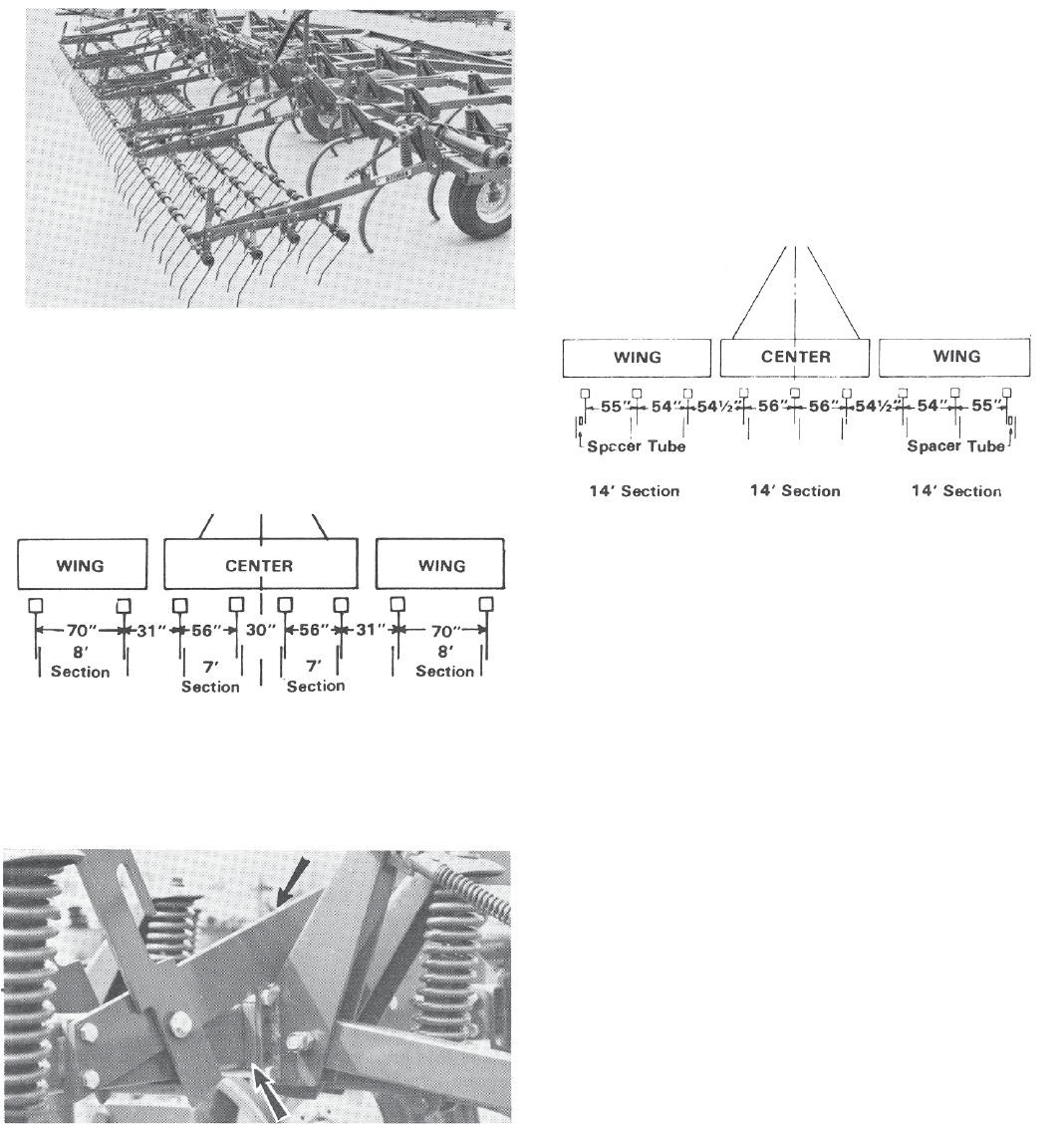

3a. The fi rst mounting bracket on each wing is located under a brace

and needs special spacers (see arrow) and longer bolts for

mounting. Summers JD1510 Chisel Plow mounting package (PN

8H1590) includes 8 spacer plates and 16 - 5/8 x 7” bolts. Spacer

plates are also supplied for use on the outer mounting bracket on

each wing so sections run perfectly square.

SPECIAL BRACKETS FOR JD1610

CHISEL PLOWS

MOUNTING INSTRUCTIONS

FOR SUMMERS MOUNTED HAR-

ROWS

Shown below is the layout of mounted harrows on a 41’ JD610 Chisel

Plow (over center fold with 12” shank spacing). Three 14’ sections are

used with three model 74 carrier arms per section. Two spacer tubes

for lateral positioning are recommended (order Summers PN 8H1502

for one spacer tube).

An optional method is to use two 7’ sections in place of one 14’ section.

Also, wing section sizes will vary with the width of the chisel plow.

SPECIAL NOTES REGARDING

JD610 MOUNTING:

1. Frame mounting brackets on the center frame cannot be more

than 56” from the machine center-line or they will interfere with the shank

standards when wings fold over center.

2. On the above layout, all lever linkage assemblies mount two

teeth in from the end of a section. Again, this may vary with different

size machines and sections.

3. When the wings of the chisel plow are folded to transport

position, they go over center and the top ends touch each other (41’

model).

To limit the travel of the mounted harrow sections as they

fold over center with the chisel plow wings, the lock collars located on

the 3/4” dia. support rods should be slid down 3” on the rod and locked

in place with a 7/16 x 1” set screw and nut. This should be done on all

three support rods per wing (41’ model). This adjustment is necessary

on all size models where top ends of wings touch each other.

4. With the above adjustment, mounted harrow sections may still

touch each other; however, the contact should be reduced to a point

where no parts bend or get permanently tangles.

18