General Preparations

Always conduct a visual inspection of the air conditioning system to identify

any damage, excessive wear, refrigerant leaks (oil residue), improper belt adjust-

ment, improper pulley alignment, and plugged condenser cooling fins.

Note: Never use water to clean the condenser or radiator fins. Using compressed

air is the approved method.

Observe the refrigerant flow through the receiver/dryer sight glass (if

equipped), use the correct gauges to check all systems, verify all system compo-

nents and controls are operable, check for loose fittings, replace defective, worn, or

damaged drive belts, and repair system leaks.

Note: The use of the sight glass alone to determine system charge level can be

misleading. Normally operating and correctly charged variable displacement

compressors and R-134a systems will have bubbles showing in the sight

glass under certain conditions.

Discharging

Caution: Refrigerant R-12 has been identified as a compound which causes

damage to the ozone layer. It is unlawful to discharge R-12 into the atmosphere.

Subaru of America encourages you to handle R-12 in a responsible and safe

manner, and according to Federal EPA guidelines and any local and state regulations.

Always follow approved recovery/recycling procedures and utilize approved

recovery/recycling equipment.

Discharging and recovery of the system refrigerant is required before replacement

of major components of the system. It is also required when the system has a leak,

or for the replacement of refrigerant oil. Discharging and recovery of the system

refrigerant is the first step in preparing for major servicing, repair,

or replacement of components; the second step is evacuation.

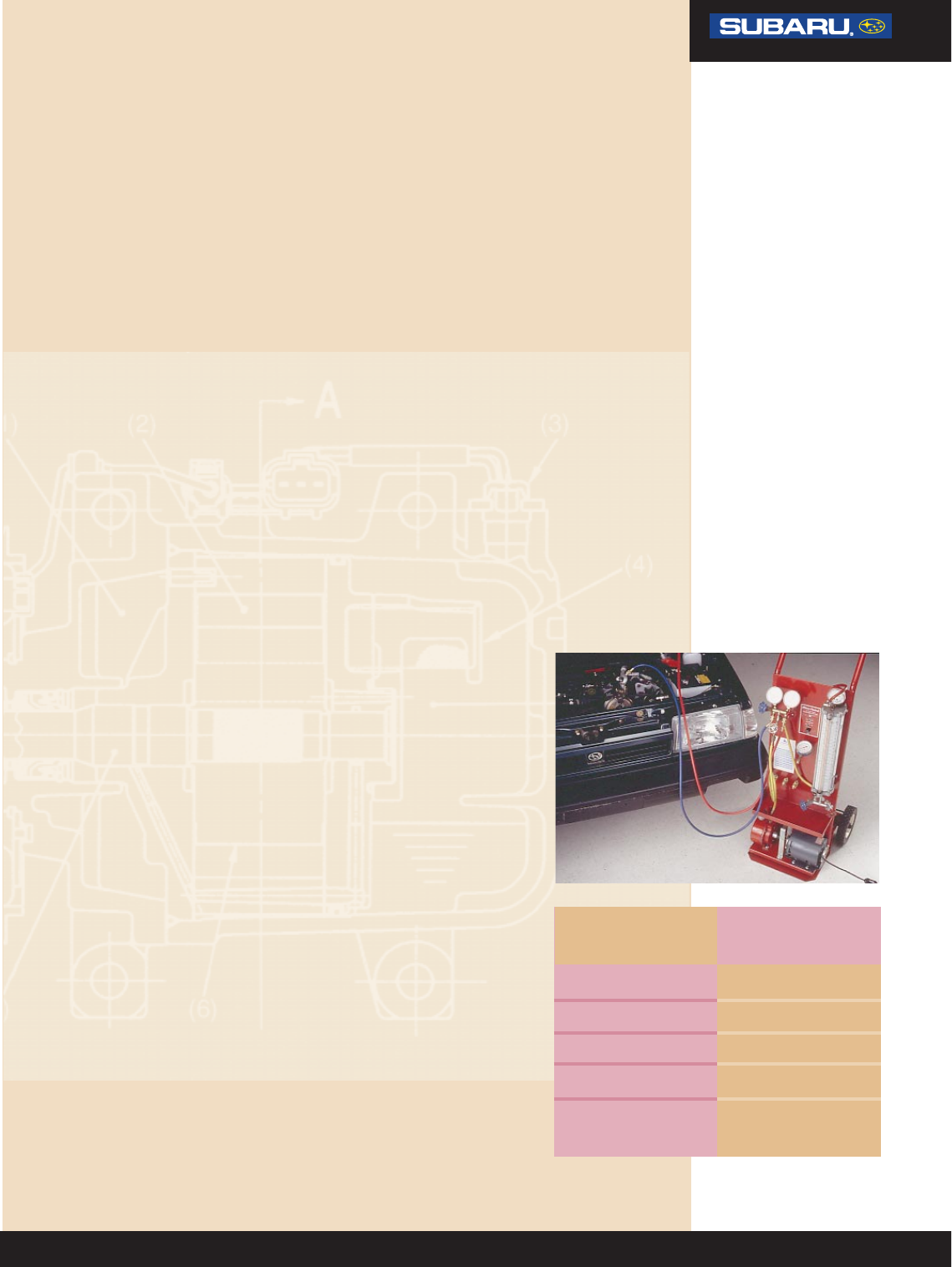

Evacuating

Evacuating the system removes air and moisture from the system.

Discharge and recover the system refrigerant first; then follow the

steps listed below to evacuate the system:

• Fully close both valves of the manifold gauge set.

• Connect a vacuum pump to the center charging hose of

the manifold gauge set.

• Start the vacuum pump.

• Open the low- and high pressure valves slowly.

• When the pressure reading has reached approximately 29.00

in Hg, fully close both valves.

• Stop the vacuum pump.

• Wait 10 minutes, the pressure reading should not change.

If it changes, there is a leak in the system.

Note: Certain types of system leaks such as loose fittings may not

be discovered using this method. Always recheck the system

with a leak detector after the system is charged.

Elevation Vacuum of System

m (ft) mm Hg, in Hg

0 (0) 710 27.95

300 (1,000) 685 26.97

600 (2,000) 660 25.98

900 (3,000) 635 25.00

Note: Values show readings of the low-pressure gauge.

Evacuating The System

Elevation/Pressure Relationship

9