69

ENGLISH

EN

5.11.2 Charging using battery charger

When charging using a battery charger, a battery

charger with constant voltage must be used.

Contact your dealer to purchase a battery charger

with constant voltage.

The battery can be damaged if a standard type

battery charger is used.

5.11.3 Removal/Installation

The battery is placed under the engine casing. Dur-

ing removal/installation, the following applies re-

garding connection of the cables:

• During removal. First disconnect the black ca-

ble from the battery’s negative terminal (-).

Then disconnect the red cable from the battery’s

positive terminal (-).

• During installation. First connect the red cable

to the battery’s positive terminal (+). Then con-

nect the black cable to the battery’s negative ter-

minal (-).

If the cables are disconnected/connect-

ed in the wrong order, there is a risk of

a short-circuit and damage to the bat-

tery.

If the cables are interchanged, the gen-

erator and the battery will be damaged.

Tighten the cables securely. Loose ca-

bles can cause a fire.

The engine must never be driven with

the battery disconnected. There is a risk

of serious damage to the generator and

the electrical system.

5.11.4 Cleaning

If the battery terminals are coated with oxide, they

should be cleaned. Clean the battery terminals with

a wire brush and lubricate them with terminal

grease.

5.12 Air filter, engine

A damaged air filter allows contaminat-

ed air into the engine. This will cause se-

rious damage to the engine.

The air filter must be cleaned after every 50 hours

of operation. The oil filter must be replaced as nec-

essary, or after every 500 hours of operation.

NOTE! Clean/replace the filter more often if the

machine operates in dusty conditions.

Remove/install the air filters as follows.

1. Disconnect the splash guard (23:G) by remov-

ing the nuts (23:K).

2. Clean carefully around the air filter housing.

3. Disconnect the air filter housing by slackening

off the wing nut (23:H).

4. Remove the filter (24:I) by slackening off the

ridged nut (24:J).

Never direct the flow of compressed air

towards the body. The penetration of

air into the blood stream can be fatal.

5. Clean off any dry dirt on the filter by blowing

compressed air in and out of the filter. The pres-

sure must not exceed 5 bar.

Check for cracks or other damage after clean-

ing. This can be visually checked against a light

source.

Check that the filter’s mating surfaces are free

of faults.

If the filter is damaged, it must be replaced.

If the filter is contaminated by moisture/oily

dirt, it must be replaced.

6. Assemble in reverse order.

Do not use compressed air or petroleum based sol-

vents such as kerosene to clean the paper filter in-

sert. This will damage the filter.

5.13 Air intake

See 10:W. The engine is air-cooled. A blocked

cooling system can damage the engine. Clean the

engine’s air intake after 50 hours of operation.

More meticulous cleaning of the cooling system is

carried out during each basic service.

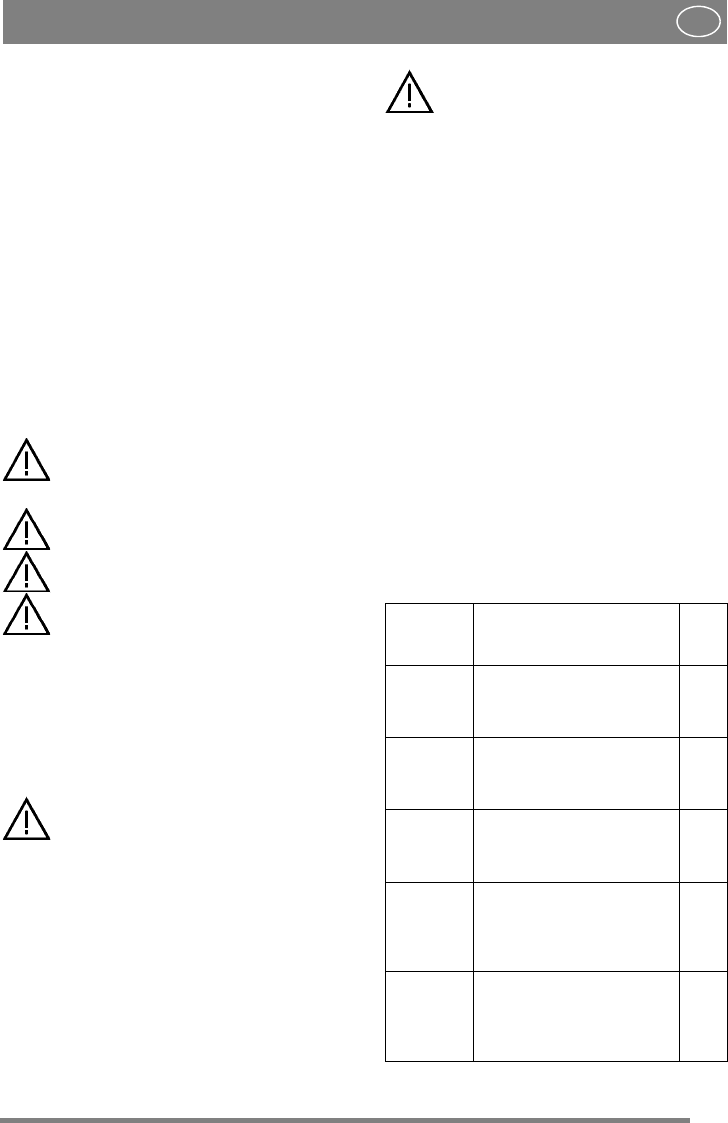

5.14 Lubrication

All lubrication points in accordance with the table

below must be lubricated every 50 hours of opera-

tion as well as after every wash.

Object Action Fig-

ure

Wheel bear-

ing

2 grease nipples.

Use a grease gun filled with

universal grease. Pump until

the grease emerges.

25

Centre point 4 grease nipples.

Use a grease gun filled with

universal grease. Pump until

the grease emerges.

26

Steering

chains

Brush the chains clean with a

wire brush.

Lubricate with universal

chain spray.

-

Tensioning

arms

Lubricate the bearing points

with an oil can when each

control is activated.

Ideally carried out by two

people.

27

Control

cables

Lubricate the cable ends with

an oil can when each control

is activated.

Must be carried out by two

people.

28