MHP3 Diesel User Manual ◄ 21

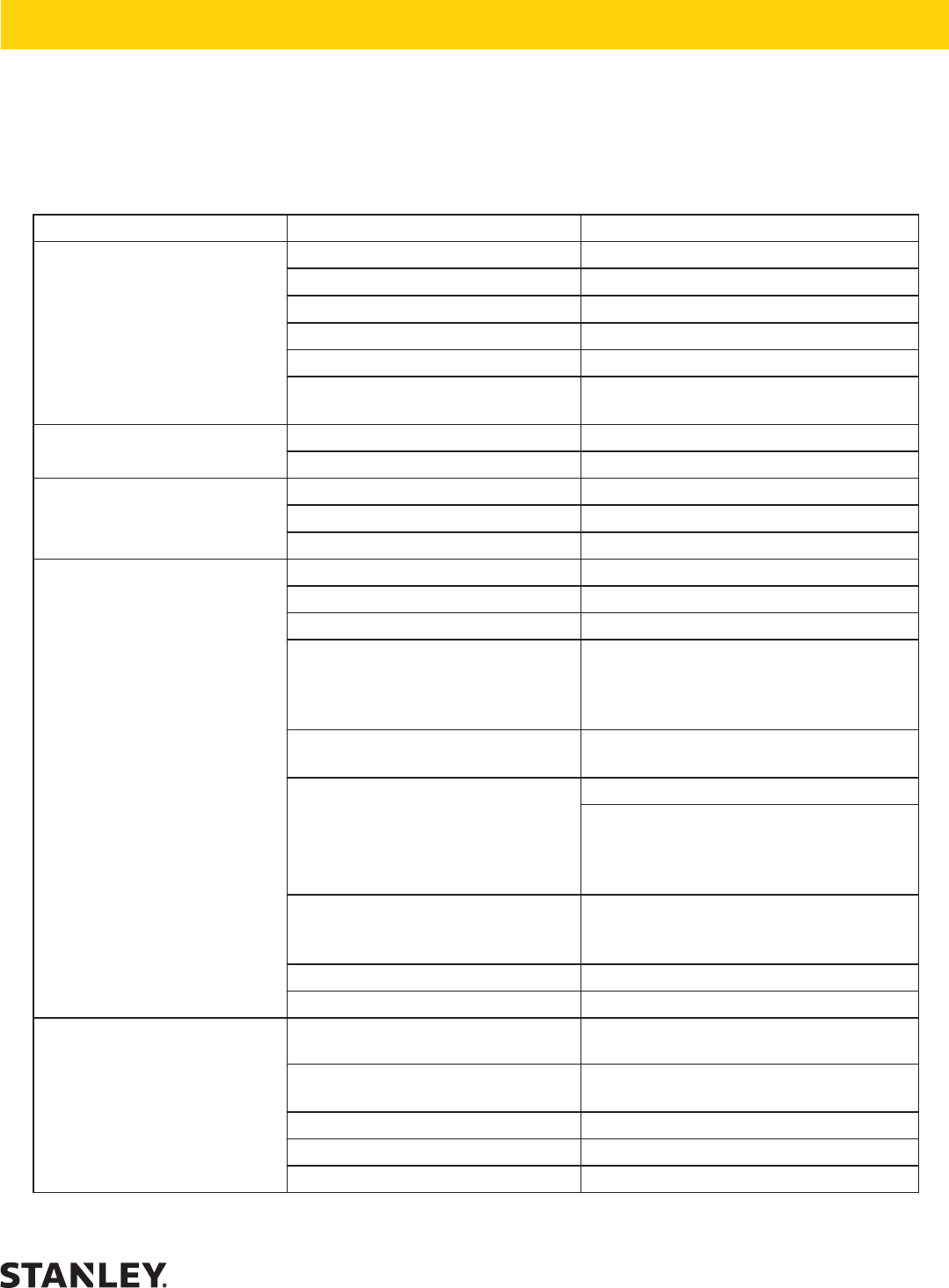

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the machine or tool, always check that the hydraulic power source is supply-

ing the correct hydraulic ow and pressure as listed in the table. Use a owmeter known to be accurate. Check the

ow with the hydraulic oil temperature at least 80 °F/27 °C.

Problem Cause Solution

Machine will not start. Fuel lter plugged. Replace fuel lter.

No fuel. Add fuel.

Tool circuit switch is on. Turn tool circuit switch off.

Battery not connected. Attach battery cables, check wires.

Weak battery. Test battery, charge or replace.

Solenoid not working. Check solenoid operation and electrical

connections.

Fluid blowing out of uid

reservoir vent.

Hydraulic tank overlled. Correct uid level.

Pump suction leak. Check suction connections.

Machine stalls when track

controls are pushed.

Not enough throttle. Increase throttle setting / use low range.

Heavy load. Increase throttle setting / use low range.

Over maximum pay load. Max load 1000/454 kg.

Hydraulic tool will not operate. Tool circuit lever is OFF. Turn tool circuit lever ON.

Not enough throttle. Move throttle to FAST position.

Incorrect tool/hose connection. Check for correct connections.

Incorrect hose connection to tool. Make sure the tool hose circuit goes from

left (pressure) tting to tool and back

to the right tting (return). Fluid always

ows from the male to female ttings.

Quick disconnect ttings. Detach from hose, connect set together

and check for free ow.

Pump coupling defective. With the engine not running.

Check the coupling between the pump

and engine that it is engaged and is not

damaged. Caution: Keep hands clear of

rotating objects.

Suction hose kinked. Make sure suction hose from uid

reservoir to pump inlet has a smooth

curve.

Tool is defective. Refer to tool manual.

Relief valve defective Have machine serviced.

Machine cannot be moved

using hydraulic controls.

Defective gear box(es). Have machine serviced.

One or more defective hydraulic

component.

Have machine serviced.

Hydraulic uid level low. Check for correct level.

Pump coupling defective. Have machine serviced.

Relief valve stuck open. Have machine serviced.

TROUBLESHOOTING