MHP3 Diesel User Manual ◄ 13

PREPARATION FOR USE

ENGINE

1.

NOTICE

Do not operate the TracHorse until you have read

the engine operating and maintenance instructions

manual furnished in addition to this manual.

Engine Crankcase Oil Level

Always check the oil level before starting the engine.

Make sure the oil level is at the FULL MARK on the

dipstick. Do not overll. Use oil as specied in the

engine operating and maintenance manual.

2.

NOTICE

The engine oil sump must never be overlled.

Overlling can cause the engine to overheat and

cause crankshaft seal damage.

Engine Fuel Level

Check the fuel level. If low, ll with DF-1 or DF-2

diesel fuel (A.S.T.M. D975-66T No. 1 or no. 2 dark).

NOTICE

Shut the engine off before attempting to add fuel to

the fuel tank. Do not remove the fuel cap while the

engine is running. Do not add fuel to the tank while

the engine is hot. Do not ll the fuel tank to a point of

overowing.

HYDRAULIC FLUID

Check the sight gauge in the hydraulic uid reservoir for

the proper uid level.

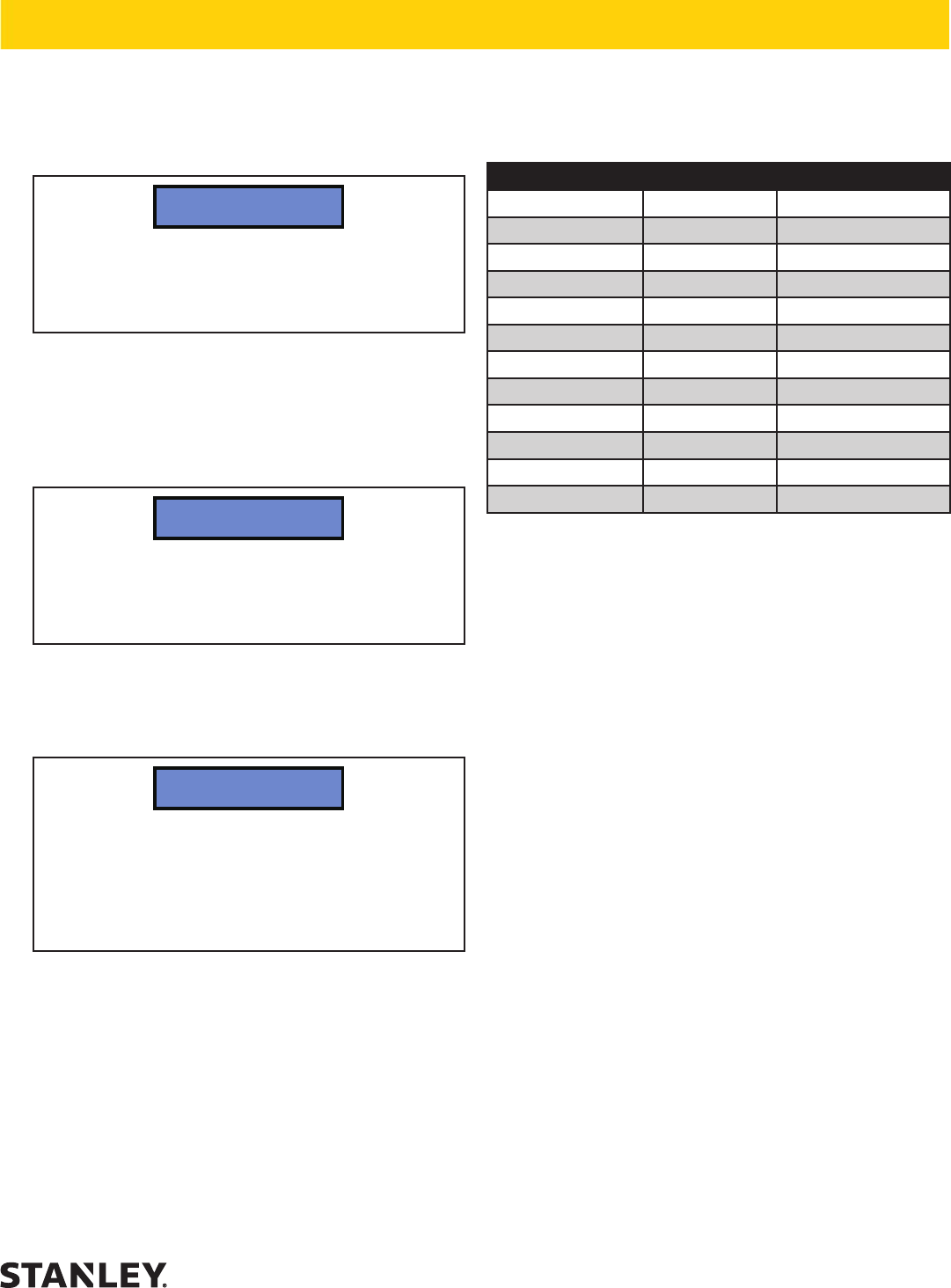

RECOMMENDED HYDRAULIC OILS

Below is a list of recommended oils by brand.

BATTERY

The supplied battery is maintenance free.

NOTE:

Before starting the engine make sure the tool circuit

switch is in the OFF position.

DUAL CIRCUIT OPERATION

Facing the panel, the male quick disconnect ttings are

the PRESSURE FLUID OUT tting. The female quick

disconnect ttings are the RETURN FLUID IN (RE-

TURN) tting.

The “Dual Circuit” control panel contains connections for

two 5 GPM tool circuits. In addition, the two circuits may

be combined into one 10 GPM tool circuit.

1. If using one 5 GPM tool circuit, select either circuit

and connect the PRESSURE FLUID OUT hose to

the male coupler and connect the RETURN FLUID

IN (RETURN) to the female coupler near to it. Con-

nect the other ends of the hoses to the tool.

If using both 5 GPM tool circuits, connect PRES-

SURE FLUID OUT hoses to the male couplers and

connect the RETURN FLUID IN (RETURN) hoses

to the female couplers. Connect the other ends of

the hoses to the tools.

2. Ensure the throttle control is depressed fully to the

idle position.

OPERATION

Brand Biodegradable Description

CITGO No Hydurance AW32

AMS Oil No HVH 32

Exxon Mobil No Univis HVI26*

Exxon Mobil No DTE 10 Excel

Shell No S2 V 32

Chevron No Rando HDZ 32

Conoco Phillips No Unax AW-WR-32

Clarion (CITGO) Yes Green Bio 32

Exxon Mobil Yes EAL 224H

Chevron Yes Clarity AW32

Terresolve Yes Envirologic 132

Shell Yes Naturelle HF-E-32

*Recommended for extreme cold temperatures