18 ► CS25/28 User Manual

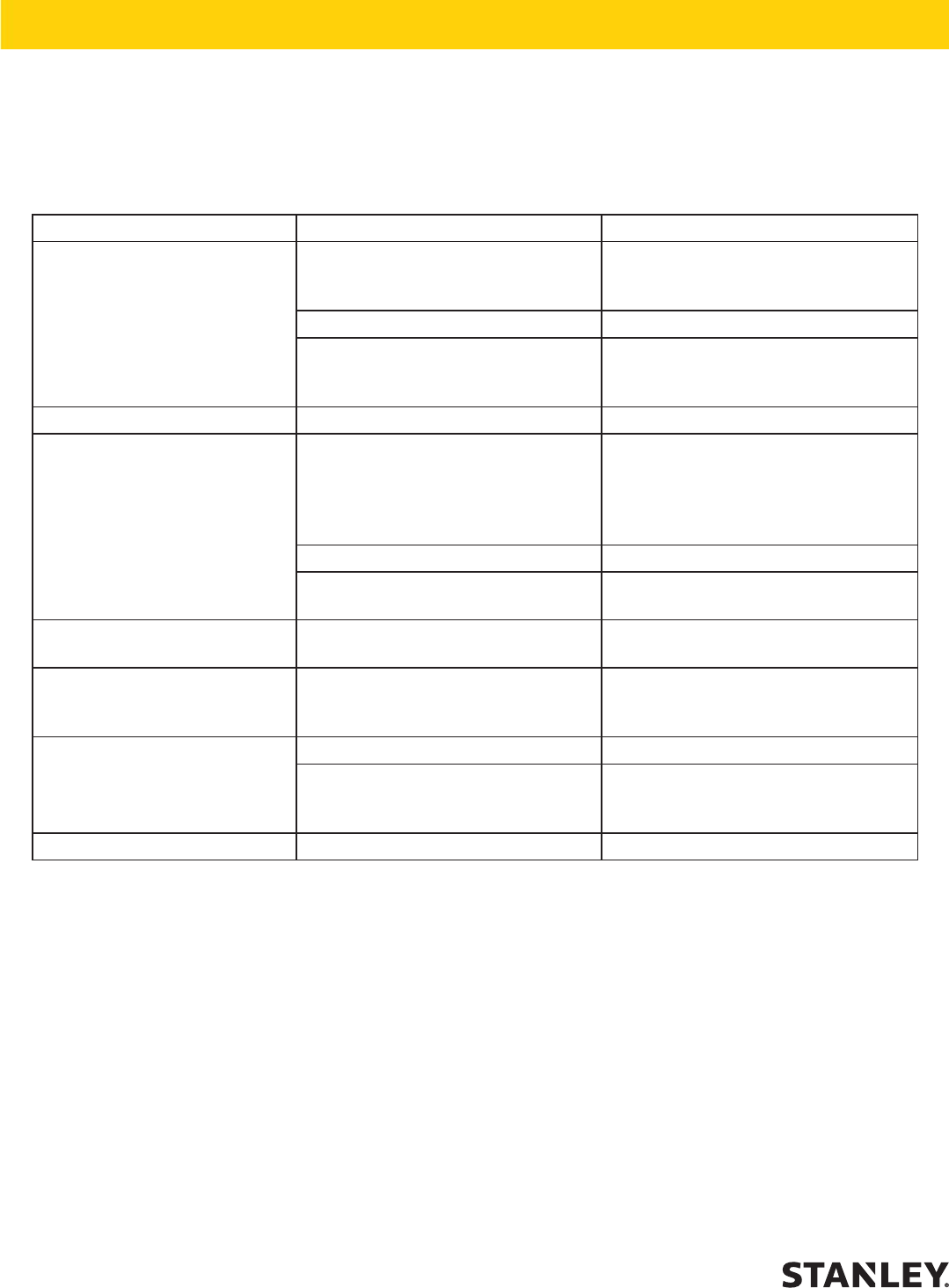

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the pole chain saw, always make sure the hydraulic power source is supply-

ing the correct hydraulic ow and pressure as listed in the table. Use a owmeter know to be accurate. Check the

ow with the hydraulic uid temperature at least 80 °F/27 °C.

PROBLEM CAUSE SOLUTION

Cuts slow. Insufcient uid ow or low relief

valve setting.

Adjust uid ow to proper gpm. For

optimum performance adjust relief

valve to 2250 psi/155 bar.

Chain dull. Sharpen per instructions or replace.

Back-pressure too high. Should not exceed 250 psi/17 bar at

rated ow measured at the end of the

tool operating hoses.

Bar turns color. Insufcient oiler ow. Adjust oiler per service instructions.

Tool does not run. Power unit not functioning. Check power unit for proper ow and

pressure 4–6 gpm/15–22 lpm at 1500

psi/104 bar minimum for CS28. 7–9

gpm/26–34 lpm at 1000 psi/70 bar

minimum for the CS25.

Coupler or hoses blocked. Remove obstruction.

Mechanical failure. Disassemble tool and inspect for

damage.

Tool runs backwards. Pressure and return hoses reversed. Correct for proper ow direction.

Motor shaft rotates clockwise.

Oil leakage around drive

sprocket.

Motor shaft seal failure. Replace as required. Make sure that

oil present is not the result of excess

oiler ow.

On/Off trigger is hard to press. Pressure and return hoses reversed. Correct for proper ow direction.

Back-pressure too high. Should not exceed 250 psi/17 bar at

rated ow measured at the end of the

tool operating hoses.

Motor sections oil leakage. Motor face seal failure. Replace as required.

TROUBLESHOOTING