Operating and maintenance instructions

ENGLISH 13

Before opening the air filter, close the choke to

prevent dirt entering the carburettor.

Turn air filter lid (22) clockwise (viewed onto the air

filter lid), and remove the lid. Remove foam filter

(27) from the lid and clean the area around the

filter.

Clean the foam filter daily, if the equipment is used

all day. Clean more frequently, if you are working

under very dusty conditions. Simply knocking the

filter casing or blowing dust from the filter bowl are

the best methods of daily maintenance. Immediately

replace the foam filter, if it shows any sign of

damage. Engine failure due to incorrect

maintenance and care are excluded from our

warranty.

Insert the new or cleaned foam filter into the air

filter lid. Position the lid onto the filter casing,

guided by the guide spigot, and lock into place with

an anti-clockwise rotation.

Never insert moist or wet foam filters!

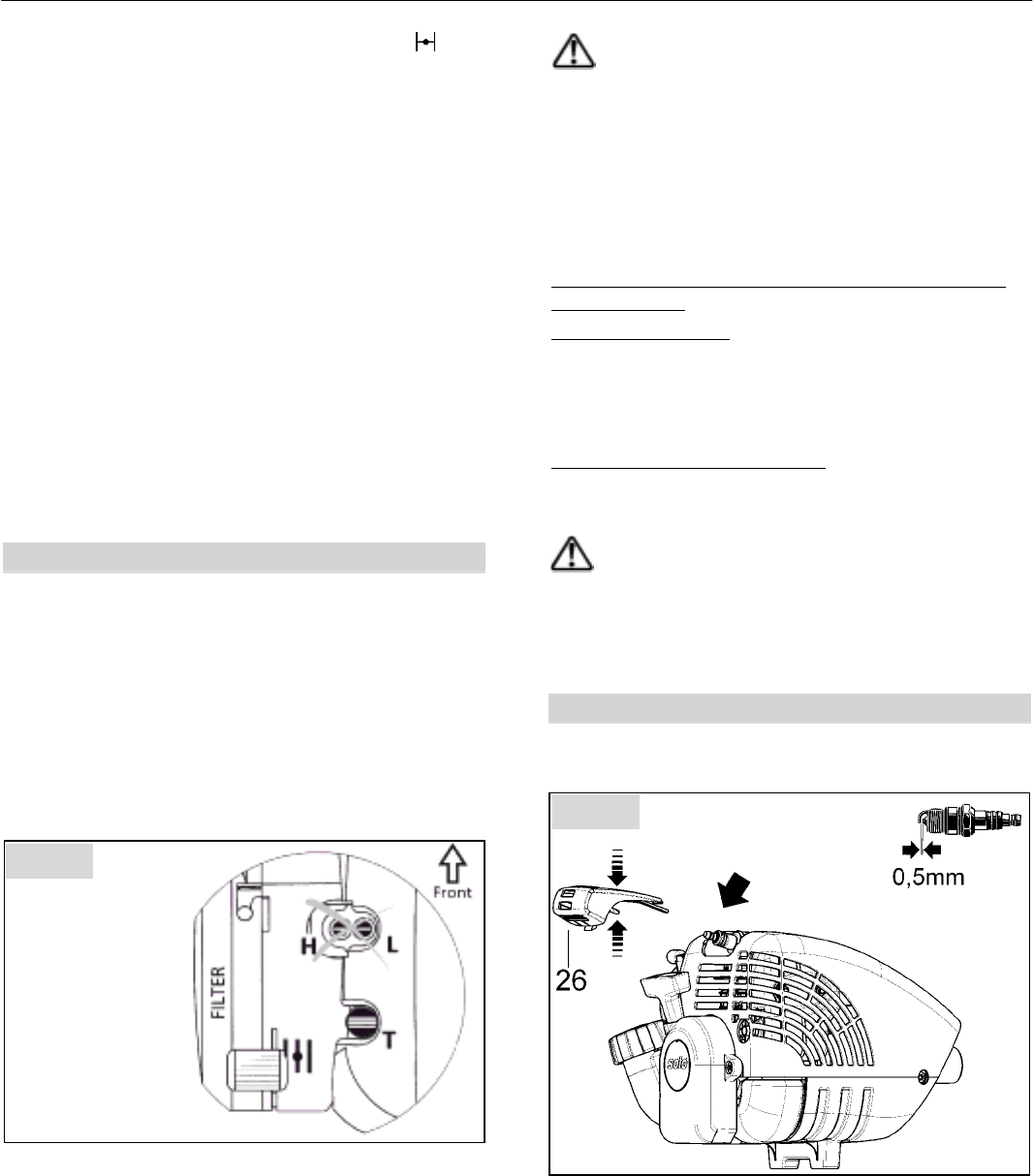

8.4 Carburettor adjustment

The carburettor has been adjusted optimally at the

factory. Subject to the operational altitude

(mountains or low lying areas), the carburettor may

require readjustment.

If the idle speed is correctly adjusted, the engine

should run without moving the blade. Slight

adjustments of the idle throttle into the average

idle speed given in the specification can be made via

the idle stop screw "T" by following the instructions

below (the use of a tachometer is recommended):

The air filter must be clean to ensure correct idle

speed adjustment. Let the engine run until it is

warm, before making any adjustments.

• If the engine idles too fast (in particular if the

power tool has already operated at idle speed),

turn the idle speed stop screw "T" anti-

clockwise.

• If the engine idles too slowly (i.e. the engine

always dies in idle), turn the idle speed stop

screw "T" clockwise a little, until the engine

runs smoothly.

Under no circumstances must the cutter be

driven at idle speed!

Only qualified mechanics must adjust the

regulating screws for idle mixture "L" and full

load mixture "H".

If the idling speed cannot be set correctly with the

idling end-stop screw "T", request an authorised

service centre to tune the carburettor.

The following instructions are for authorised

service shops

D-CUT carburettors:

Use the D-CUT carburettor key to adjust the idle

mixture screw "L" and the full load mixture screw

"H". Check with our customer service team

regarding the basic setting.

Carburettors with limiter caps:

The regulating screws for idle mixture and full load

mixture can only be adjusted in a limited range.

The carburettor is tuned for optimum engine

performance. Use a rev counter to tune the

carburettor correctly!

Do not adjust the engine to a higher speed.

Excessive engine speed can lead to major engine

damage!

8.5 Information about the spark plug

Check the spark plug regularly after 50 hours of

operation.

• Press the spark plug cover (26) together at the top

and bottom, and move it away from the engine

casing by pushing it back.

• Disconnect the spark plug cap.

• Unscrew the spark plug and dry the electrodes.

The spark plug should be replaced after 100 hours

of operation or if the electrodes are badly worn.

Do not turn the engine over while the spark plug

has been removed or the spark plug cap has been

Fig. 18

Fig. 19