Operating and maintenance instructions

ENGLISH 12

8. Operating and maintenance

instructions

The maintenance and the repair of modern

machines as well as their safety-relevant assemblies

require qualified specialised training and a

workshop equipped with special tools and test

equipment. Consequently the manufacturer

recommends that all tasks not described in these

operating instructions be carried out by a specialised

workshop. That specialist has the required training,

experience, and equipment at his disposal, to

provide you with the most cost-effective solution for

such work. He will provide additional help in word

and deed.

After a running-in time of app. 5 hours, all

accessible screws and nuts (except the carburettor

adjusting screws) must be checked for tightness and

they must be retightened, if required.

8.1 Blade

Before hedge trimming and after cleaning, treat the

clean blade with maintenance and treatment oil.

We recommend the "Solo maintenance and

treatment oil" (Part no: 00 83 163).

To clean the blade after hedge trimming, we

recommend the use of "SOLO Universal-Reiniger

(Cleaner)" (Part no: 00 83 116). After a short period

of soaking in, the ingrained remains of cuttings on

the blade are soft and solvent. They can then be

removed easily with a cloth.

Check the blade at regular intervals and when

cutters operate unusually or if the blades are

jammed. For this, the engine must be switched off

and the blade must be stopped. Clean cuttings,

undergrowth etc. from the blade. Immediately

replace blunt or damaged tools, even if only slightly

damaged.

Sharpening the cutting blade

Sharpening of the cutting blade must only be

carried out by an authorised agent.

• Sharpening angle: 45°

• Always sharpen towards the cutting edge

• Only work with a forward stroke

• Following sharpening, remove the burr with a

whetstone and spray the blade with a

maintenance and treatment oil.

8.2 Gear lubrication

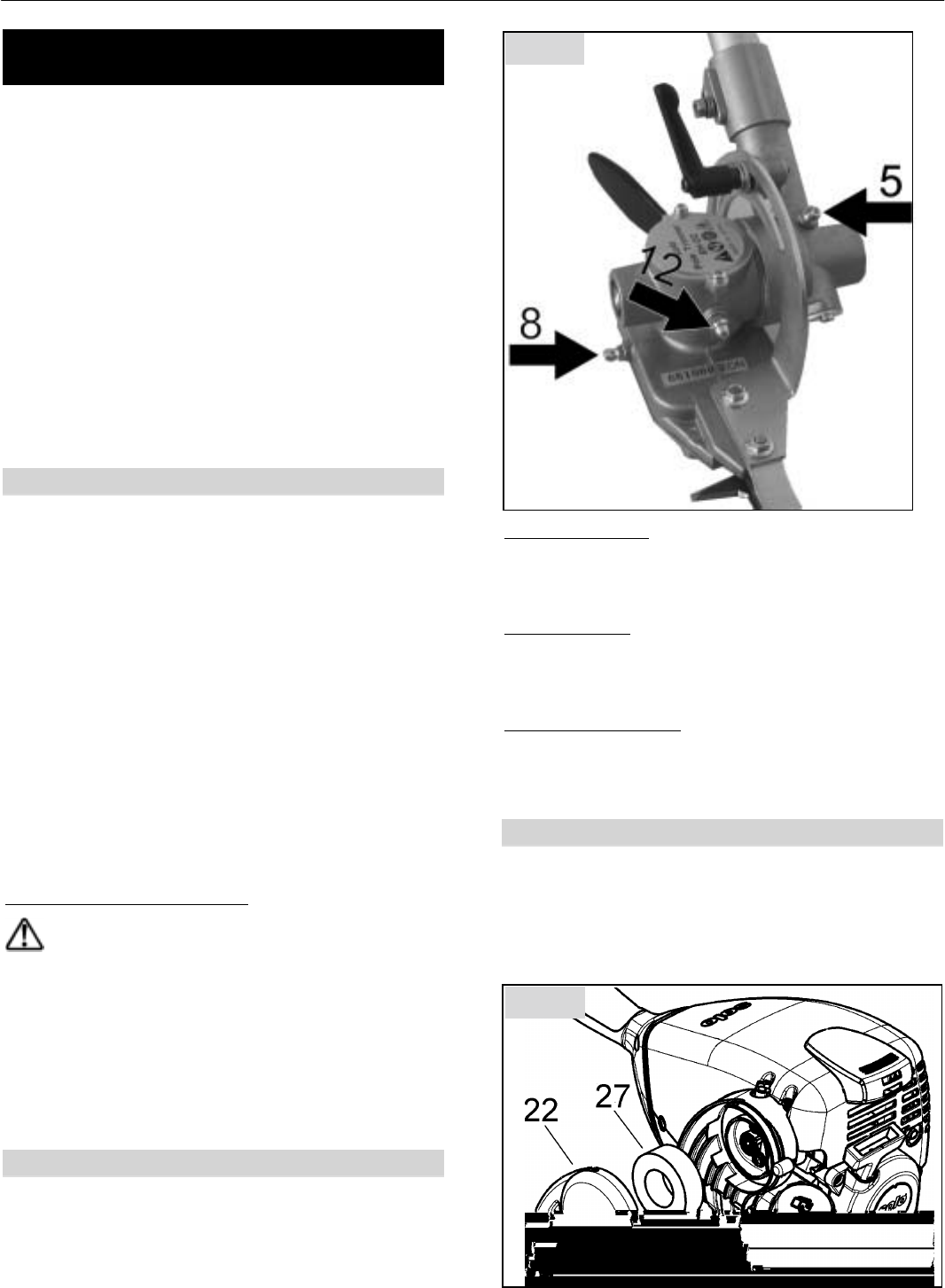

Re-lubricate the blade gearbox (8), angular gear (5)

and clutch mid-section (12) with SOLO "Special

gearbox flow grease" (part no.

00 83 180) approx. Every 20 operating hours.

Cutter gearbox:

With a grease gun, press about 20g gearbox flow

grease into the blade gearbox grease nipple (8) (3-5

shots).

Angular gear:

With a grease gun, press about 10 g gearbox flow

grease into the angular gear grease nipple (5) (2-3

shots).

Clutch mid-section:

With a grease gun, press about 20g gearbox flow

grease into the clutch mid -section grease nipple

(12) (3-5 shots).

8.3 Air Filter Maintenance

Contaminated air filters cause a reduction in engine

performance and increase fuel consumption with

more pollutants in the exhaust gas. Engines are less

likely to start readily with a contaminated air filter.

Carry out the following maintenance jobs regularly.

Fig. 16

Fig. 17