30

Troubleshooting, Adjustments, & Service

TRANSMISSION DRIVE BELT

REPLACEMENT

1. Park the rider on a smooth, level surface such as a

concrete floor. Disengage the PTO, lock the motion

control levers into their neutral locked positions, turn

off the engine, and remove the ignition key.

2. Remove the mower belt from the PTO pulley (see

MOWER BELT REPLACEMENT for instructions).

3. Relieve tension on the transmission belt (A, Figure

33a) by moving the idler arm (E) in the direction indi-

cated by the curved arrow, and remove the old belt

from the crankshaft and transmission pulleys.

4. Loosen (do not remove) the anti-rotation bracket

hardware (C, Figure 33a), and slip the old belt out

between the anti-rotation pin (B) and the PTO (A).

Note: The PTO wiring harness must be disconnected

from the main wiring harness in order to remove and

replace the transmission belt. Be sure to reconnect the

harness after the belt is replaced.

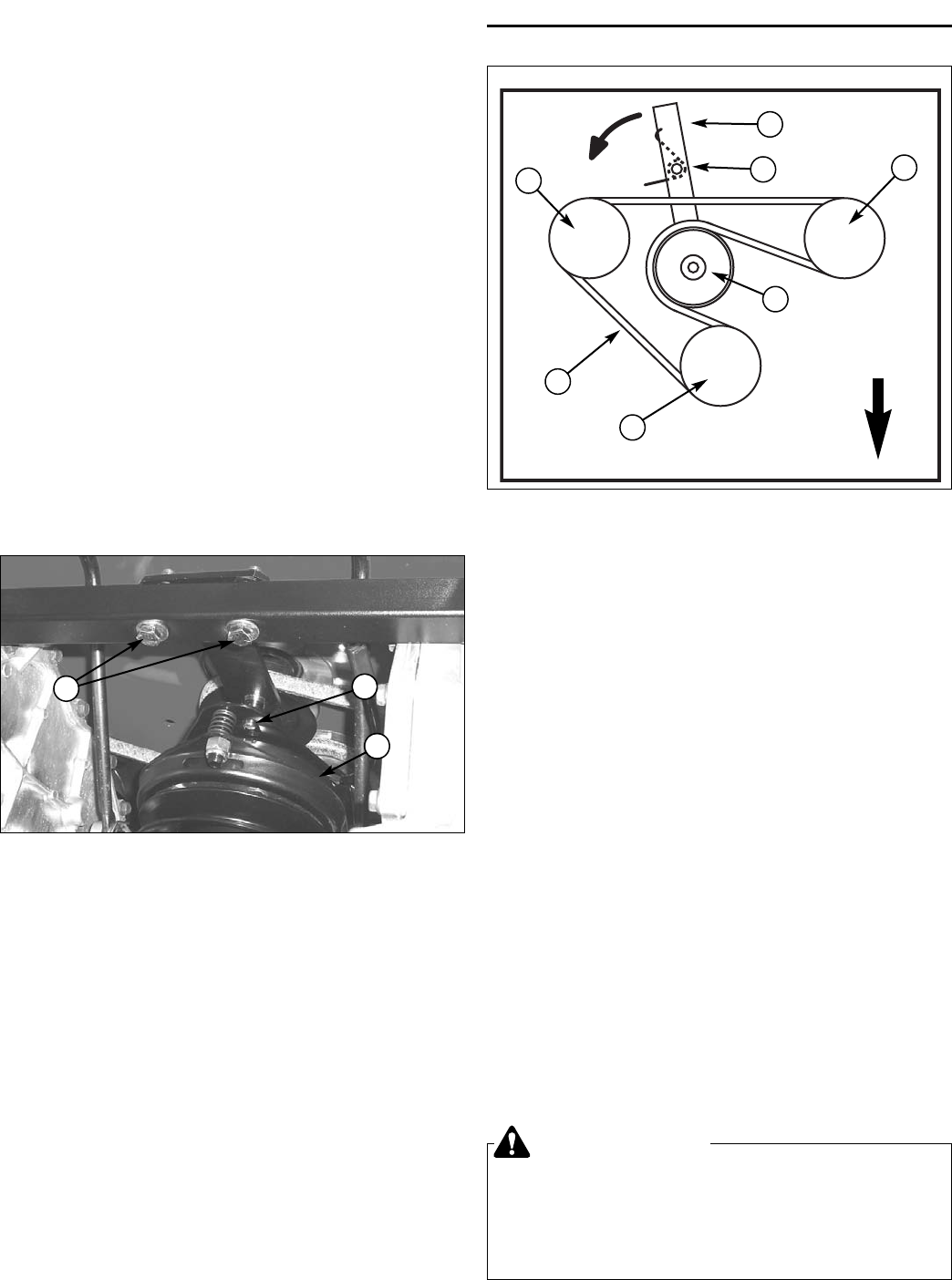

Figure 33b. Transmission Drive Belt Replacement

(Shown from Below; Components Removed for

Clarity)

A. Transmission Drive Belt

B. Crankshaft Pulley

C. Transmission Pulley (2)

D. Idler Pulley

E. Idler Arm

F. Idler Tension Spring

F

BATTERY CHARGING

A dead battery or one too weak to start the engine may

be the result of a defect in the charging system or other

electrical component. If there is any doubt about the

cause of the problem, see your dealer. If you need to

replace the battery, follow the steps under Cleaning the

Battery & Cables in the Regular Maintenance Section.

To charge the battery, follow the instructions provided by

the battery charger manufacturer as well as all warnings

included in the safety rules sections of this book.

WARNING

Keep open flames and sparks away from the

battery; the gasses coming from it are highly

explosive.Ventilate the battery well during

charging.

C

D

C

FRONT

B

A

E

Remove the battery from the rider and place on a level,

non-concrete surface. Charge the battery at 6-10 amps

for 1 hour. Do not charge at a rate higher than 10 amps.

Figure 33a. Anti-Rotation Bracket

(View Looking Back from Mower Deck)

A. PTO Clutch

B. Anti-Rotation Pin

C. Anti-Rotation Bracket Hardware

A

B

C

5. Reversing steps 3-4, install the new belt, following the

routing in Figure 33b. Make sure the V-side of the

belt runs in the grooves of the crankshaft pulley and

transmission pulleys (B & C). Also, make sure that

the anti-rotation pin (B, Figure 33a) is inserted into

the anti-rotation slot on the PTO before tightening

hardware (C).

6. Reinstall the PTO drive belt.