Troubleshooting, Adjustments, & Service

25

NEUTRAL ADJUSTMENTS

If the machine creeps while the motion control levers are

locked into their neutral locked positions, then it may be

necessary to adjust the link rods.

Perform this adjustment on a hard level surface such as

a concrete floor.

IMPORTANT NOTE:This adjustment should be per-

formed with the engine OFF. Perform the adjustment,

then start the engine to check the adjustment. If further

adjustment is required, stop the engine before perform-

ing the adjustment.

1. Determine which wheel is creeping. The left side

transmission and link rod control the left wheel, the

right link rod controls the right wheel.

2. Disengage the PTO, lock the motion control levers

into their neutral locked positions, turn the engine off,

remove the key, and wait for all moving parts to stop.

3. Remove the hardware (C, Figure 23) connecting the

rod end (B) to the control bracket weldment (A).

Note: The rod end is located under the fender beside

the operator seat.

4. Loosen the rod end jam nut (B).

If the transmission is creeping forward, turn the rod

end in (clockwise) one or two turns to shorten the link

rod (E).

If the transmission is creeping in reverse, turn the rod

end out (counterclockwise) one to two turns to length-

en the link rod.

5. Retighten the jam nut, and reconnect the rod end to

the control bracket weldment.

6. Start the unit and check for transmission creep.

Repeat steps 2-5 if necessary.

7. Once the correct adjustment is achieved, check

adjustment of the compression spring (F). With the

motion control levers in their neutral locked positions,

the spring should have no compression, and should

have approximately 1/16-1/8” of free play between the

washers at either end. Turn the two adjustment nuts

(G) in or out until the desired adjustment is achieved.

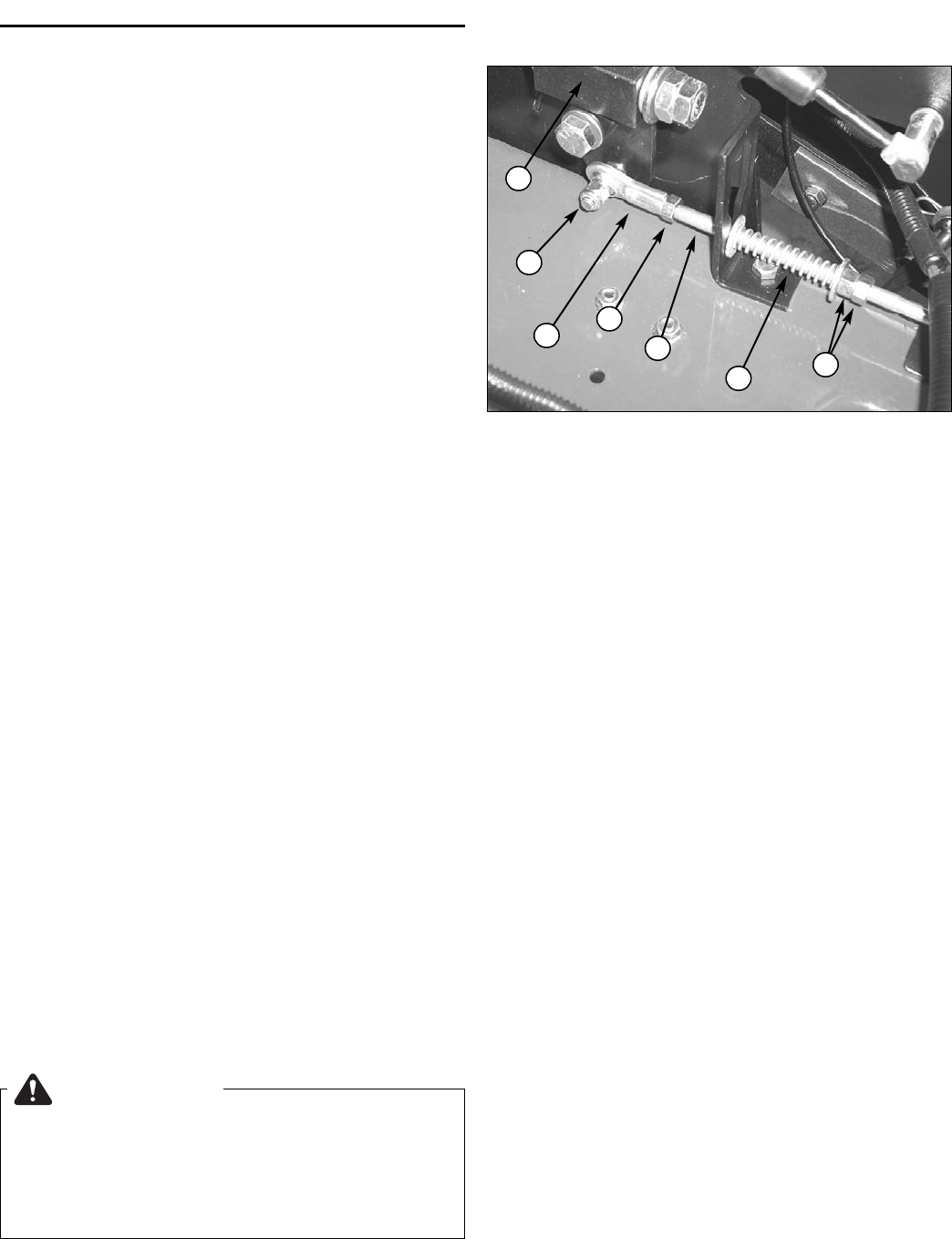

Figure 23. Neutral Adjustment

A. Control Bracket Weldment

B. Rod End

C. Rod End Connecting Hardware

D. Jam Nut

E. Link Rod

F. Compression Spring

G. Spring Adjustment Nuts (2)

B

D

C

E

F

A

G

WARNING

Incorrect adjustment of the compression springs

can cause motion control levers to move from

neutral into forward or reverse. This can cause

unexpected machine movement, and may result in

possible injury and/or equipment damage.