Page 8

WHEEL LOCKOUTS (7016RT)

Place wheels in tilling position.

1. Pull knob in center of wheel out, away from machine.

2. Rotate knob and lockout to align with slot on axle,

release knob. Rotate wheel to align slot in wheel hub

with lockout.

3. Wheel and axle should be firmly locked together

before tilling.

4. Repeat for other wheel.

NOTE: Always have both wheel lockouts in or out.

Do not operate tiller with only one wheel locked.

To place wheels in free-wheel position.

1. Pull knob in center of wheel out, away from machine.

2. Rotate knob and lockout to align lockout with detent

in end of axle. Release knob.

3. Wheel should turn freely on axle.

WHEEL LOCKPINS (6016RT)

Place wheels in tilling position.

1. Remove lockpin. Align hole in axle with hole in wheel

hub.

2. Insert lockpin through holes, fold lockpin ring to

secure pin to axle.

3. Wheel and axle should be firmly locked together

before tilling.

4. Repeat for other wheel.

NOTE: Always have both wheel lockouts in or out.

Do not operate tiller with only one wheel locked.

To place wheels in free-wheel position.

1. Remove lockpin. Slide wheel inward toward machine.

2. Insert pin in axle only.

3. Wheel should turn freely on axle.

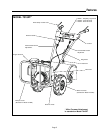

Model

6016RT

(6-hp)

Wheel lockpin in free-wheel position.

(axle hole only)

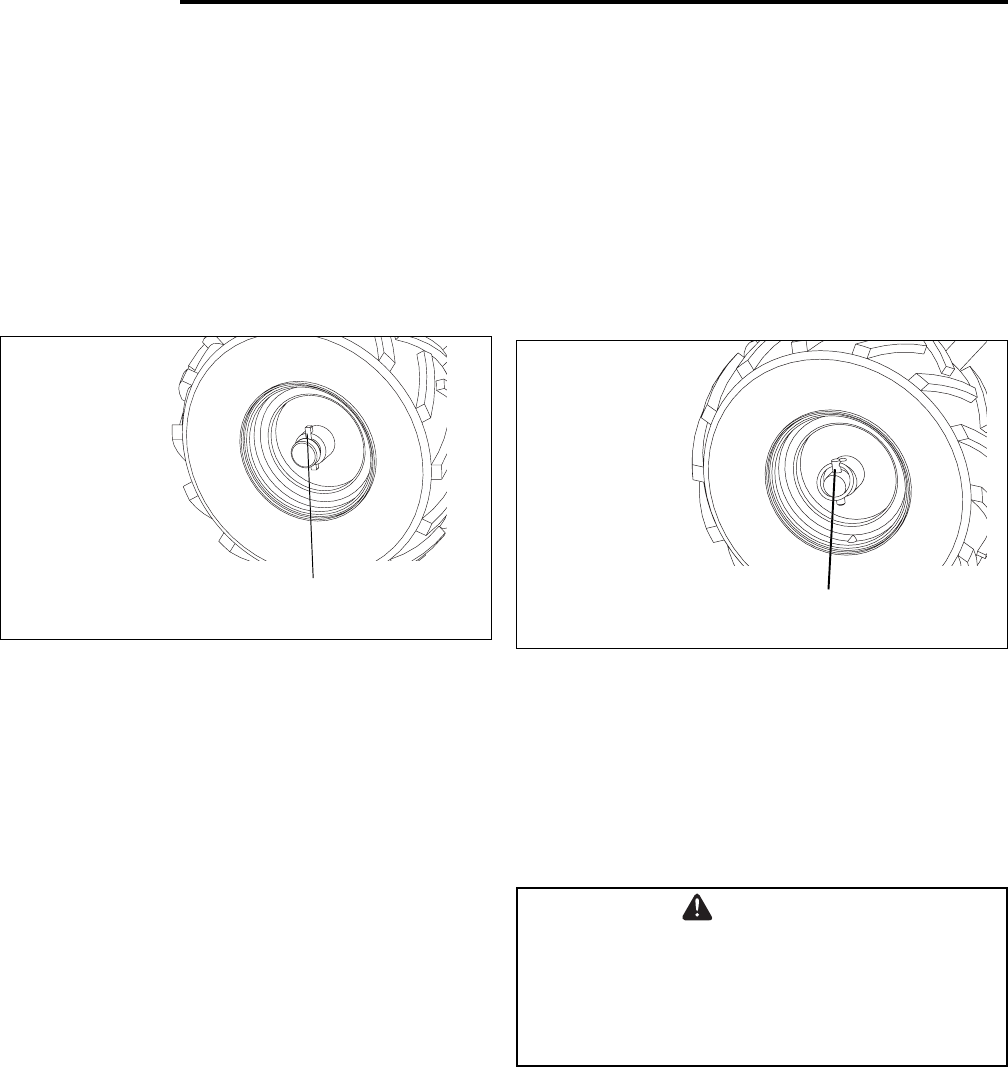

Wheel lockout in tilling position.

(hub & axle slot)

Model

7016RT

(7-hp)

Never start engine or operate tiller with wheels in

free-wheel position. The free-wheel position is for

transporting the tiller long distances over level

ground--do not attempt to move the tiller up or

down steep grades in the free-wheel position.

Adjustments

WARNING