Oil:

• control handle pivots

• floor plate hinge

• discharge chute hinge

Generally, all moving metal parts should be oiled

where contact is made with other parts. Keep oil and

grease off belts and pulleys. Remember to wipe fit-

tings and surfaces clean both before and after lubri-

cation.

16

LUBRICATION

Lubricate the unit at the following lubrication points.

Grease:

• front caster wheel axles

• motion control pivot bearings

• suspension a-arms

• mower deck pusher bars

• deck lift pivots

• deck lift foot pedal

• front pivot frame

• mower deck idler arm

• mower deck caster pivots

Use grease fittings when present. Disassemble parts

to apply grease to moving parts when grease fittings

are not installed.

Not all greases are compatible. Ferris Red Grease

(part #22285) is recommended, automotive-type high-

temperature, lithium grease may be used when this is

not available.

Regular Maintenance

BATTERY MAINTENANCE

Checking the Battery Fluid

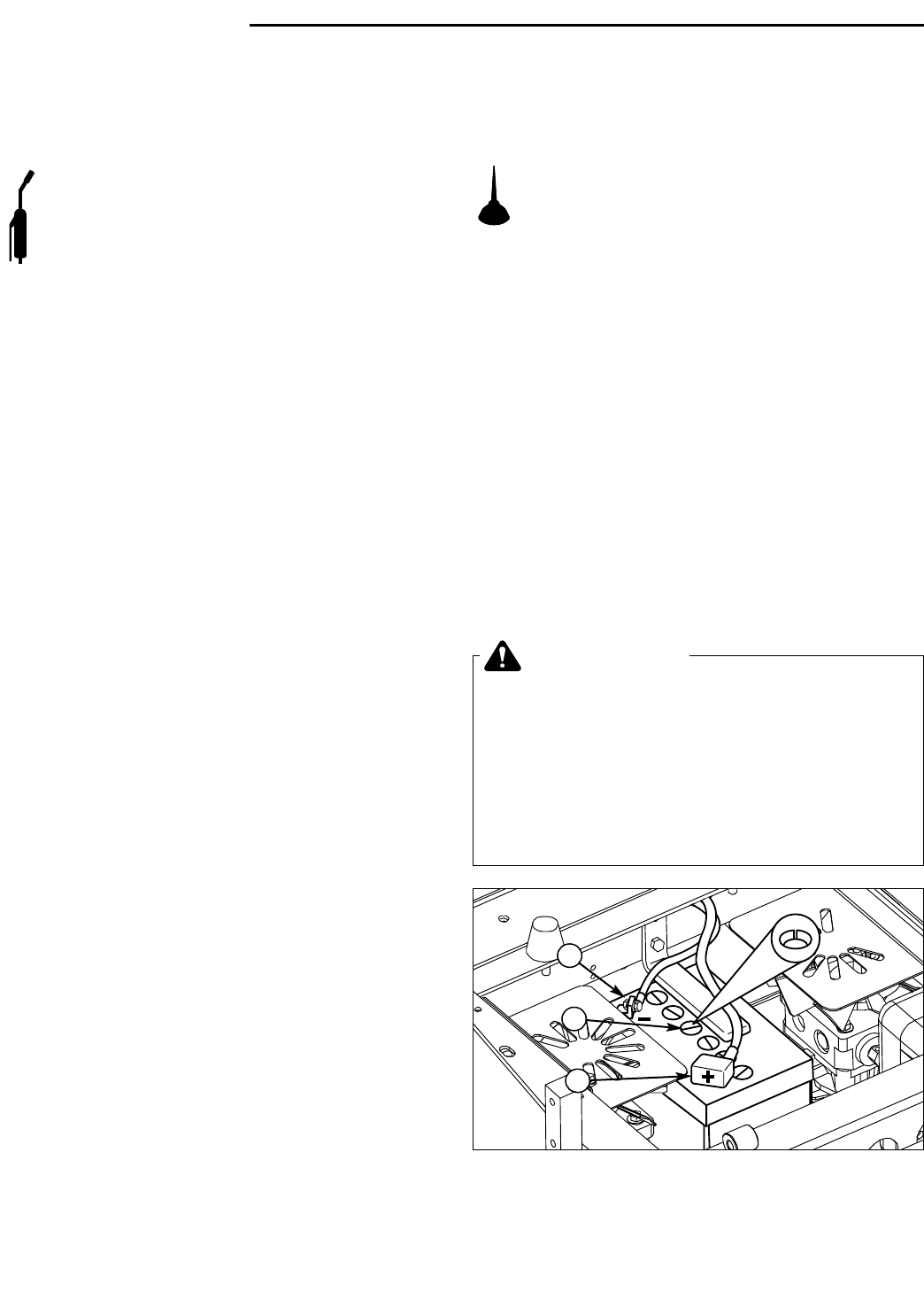

1. Raise the seat plate to access battery.

2. Remove the battery filler cap (A, Figure 15). Fluid

must be even with the split ring full mark. If not, add

distilled water.

3. Reinstall the filler cap.

Cleaning the Battery and Cables

1. Disconnect the cables from the battery, negative

cable first (C, Figure 15).

2. Clean the battery terminals and cable ends with a

wire brush until shiny.

3. Reinstall the battery and reattach the battery cables,

positive cable first (see B, Figure 15)

4. Coat the cable ends and battery terminals with petro-

leum jelly or non-conducting grease.

A

B

C

Figure 15. Battery Compartment

A. Vent Cap(s)

B. Positive (+) Cable & Terminal

C. Negative (-) Cable & Terminal

WARNING

Be careful when handling the battery. Avoid

spilling electrolyte. Keep flames and sparks away

from the battery.

When removing or installing battery cables,

disconnect the negative cable FIRST and reconnect

it LAST. If not done in this order, the positive

terminal can be shorted to the frame by a tool.