13

SECTION 2 – OPERATING INSTRUCTIONS

2.1 PRE-START CHECK LIST

Make the following checks and perform all service as

required before starting and operating the machine.

2.1.1. Read Manuals. Read, understand, and follow

instructions and warnings in this manual and all other

supplied manuals, as well as instructions and warnings

on the machine, engine and attachments. Know the

controls and the proper use of the machine before

starting.

2.1.2. Perform General Inspection. Thoroughly

inspect the entire machine for damage, wear, and loose

and missing hardware. Repair or replace damaged,

worn, loose and missing components prior to starting

and operating machine.

2.1.3. Check Tires. Check and adjust tire pressure to

15 psi. front and rear. Inspect condition of tires for

wear, deterioration, cuts, and damage. Replace worn,

damaged or deteriorated tires before operating

machine, using only tires of original size, type and

construction.

2.1.4. Check Accelerator Pedal. With engine off,

depress pedal fully. The pedal must move freely, and

immediately return to original position when released.

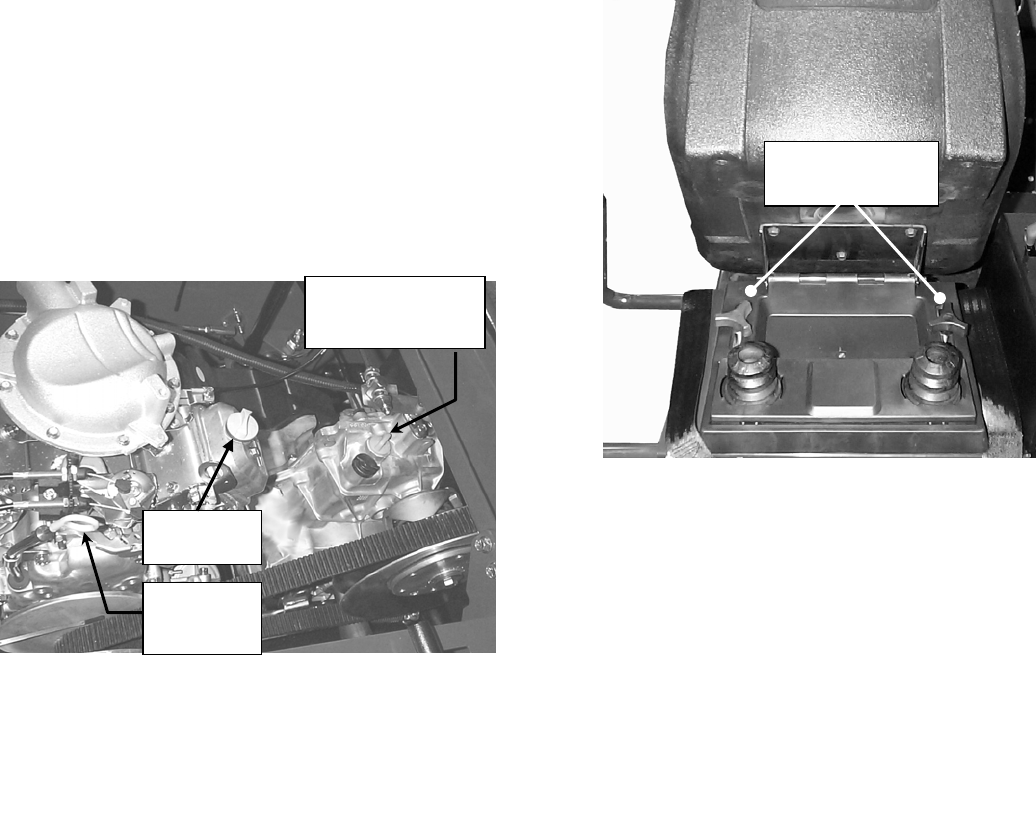

2.1.5. Check Engine oil and Transmission fluid.

Raise empty cargo bed and carefully secure with prop

rod. Add oil as needed to bring engine to FULL mark

on dipstick. See Figure 2.1. Refer to Engine Owner’s

manual for engine oil specifications. Add fluid as

needed to bring transmission to FULL mark on dipstick.

See Figure 2.1. Use MOBILFLUID 424 or equivalent.

IMPORTANT! Do Not overfill. Always fully thread dip stick

when checking transmission fluid levels.

FIGURE 2.1

2.1.6. Add Fuel to tank. (Refer to Engine Owner’s

manual for fuel specifications.) Make sure fuel filler cap

is tight after fueling. IMPORTANT NOTE: Always fuel

machine out of doors, where fumes can safely

dissipate. Do not smoke while fueling.

2.1.7. Check Steering for excessive play. Do not

operate machine if steering is loose or sloppy.

2.1.8. Check Headlights. Both headlights should be

functional before operating machine. Headlight lenses

and rear reflectors must be clean. (NOTE: Ignition

must be set to ‘Run’ position for headlights to function.)

2.1.9. Check Engine and surrounding areas for

buildup of dirt, debris, oil, grease, etc.

IMPORTANT! ENGINE AND SURROUNDING AREAS

MUST BE KEPT CLEAN. Debris buildup can cause

engine overheating, severe damage, and fire.

2.1.10. Adjust Operator’s Seat. With engine stopped,

and park brake set, loosen two seat adjusting knobs

and move seat to desired position. Re-tighten both

knobs securely. See Figure 2.2.

FIGURE 2.2

2.1.11. Check Seat Belts. Mounting hardware must

be tight. Buckle must latch securely. Webbing must

not display signs of deterioration, wear, or damage.

2.1.12. Check Operator Protective Structure (OPS).

Check OPS for structural soundness (i.e. cracks,

damage, etc.) All OPS mounting hardware must be

tight. DO NOT operate a machine that has had the OPS

removed, damaged, or modified in any way.

SEAT ADJUSTING

KNOBS

ENGINE

OIL FILL

TRANSMISSION

FLUID

DIPSTICK/FILL

ENGINE

OIL

DIPSTICK

13