21

AIR FILTER REPLACEMENT/SERVICE

The engine air filter element filters and removes airborne

dirt, dust, and other work site debris from the air before it

can enter the carburetor and damage sensitive fuel pas-

sages.

Depending on the type of air filter element installed on

your chipper/shredder engine, you should periodically

perform one of the following steps:

Oil Foam Element:

• Clean the element in a safe solvent (not gasoline

because it is flammable) and dry with a paper towel

• Moisten the element with clean engine oil

• Ring out the excess oil with a paper towel

Paper Element

• Shake/blow out any debris caught in the element

• Inspect the element and replace if it is dirty or discol-

ored, clean and oil the air filter (foam filter only),

Note: Consult the engine manufacturer’s manual for

additional recommendations.

If you have any doubts about what type of filter element

you have, consult you local authorized dealer for help.

INSPECT STARTER ROPE & HANDLE

The recoil starter rope and handle should be inspected

for signs of abrasion or wear that could result in break-

age. It is much easier to replace a frayed rope than a

broken one.

Regular Maintenance

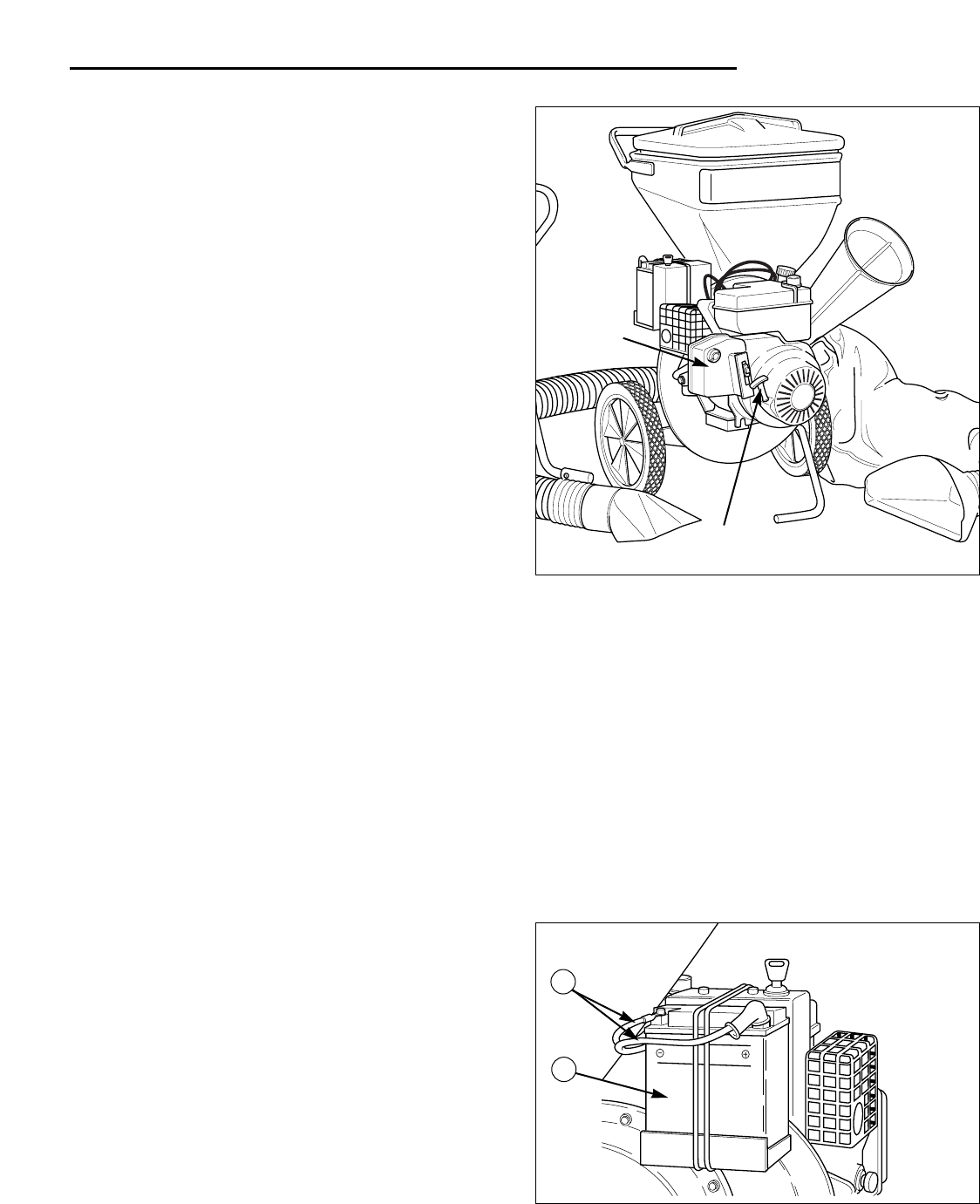

Figure 19. Air Filter and Recoil Starter Location

Air Filter

INSPECT BATTERY

& ELECTRICAL CONNECTIONS

The battery should be inspected and cleaned every 100

hours of service or as needed. Check the electrolyte

level and fill with distilled water if necessary. Fill the cells

up to the bottom of the inside split ring. Clean and

inspect the battery cables and terminals. Replace if cor-

roded.

Figure 20. Battery and Cables

A. Battery B. Cables

A

B

Recoil

Starter