18

Combustion chamber should be decarbonized, and the valve clearance should be adjusted. It is highly recommended ■

that this is done by a Shindaiwa-trained service technician.

Replace the spark plug annually: Use only the type recommended in the ”Specications” section or an equivalent resis-

■

tor type spark plug of the correct heat range. Set spark plug electrode gap to 0.6 mm (0.024 in).

Maintenance (continued)

50-hour maintenance

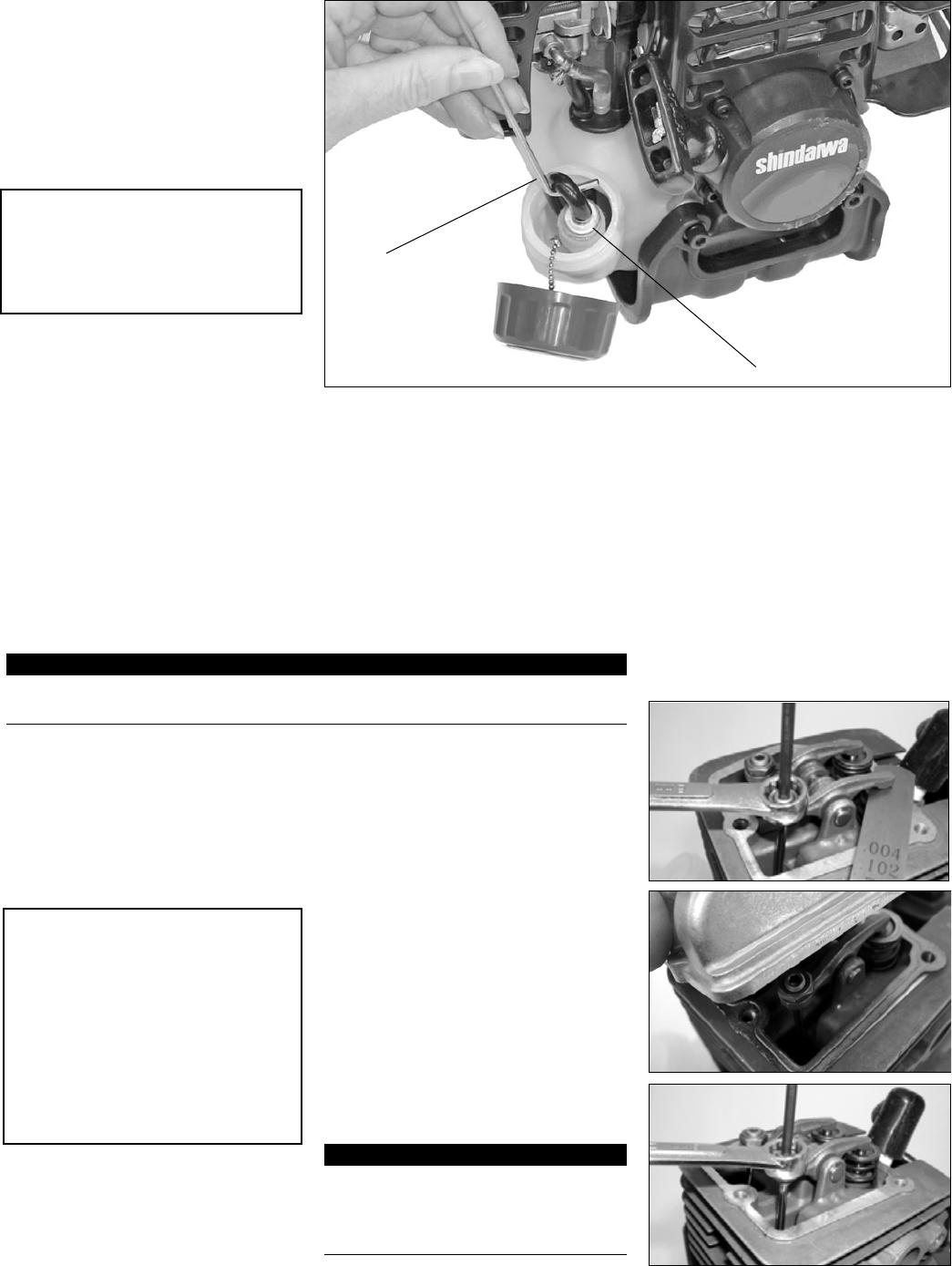

Remove and replace the fuel lter

element.

Use a hooked wire to extract the fuel ■

lter from inside the fuel tank. Inspect

the fuel lter element. If it shows signs

of contamination, replace with a genu-

ine Shindaiwa replacement fuel lter

element.

CAUTION!

Make sure you do not pierce the fuel

line with the end of the hooked wire.

The line is delicate and can be dam-

aged easily.

135-Hour Maintenance

Before reinstalling the new lter ele- ■

ment, inspect the condition of all the

fuel system components (fuel pick-

up line, fuel return line, tank vent

line, tank vent, fuel cap and fuel

tank). If damage, splitting or dete-

rioration is noted, the unit should

be removed from service until it can

be inspected or repaired by a Shin-

daiwa-trained service technician.

IMPORTANT!

If a new gasket is not available and/

or the old gasket is not damaged, the

old gasket may be reused. Never use

cracked or damaged gaskets!

Turn adjustment screw (clockwise = 4.

tighter, counter-clockwise = looser)

until feeler gauge is almost snug.

Back off just enough to allow gauge

to slip out with limited resistance.

While holding the adjustment 5.

screw in place with the Allen driver,

tighten the locknut with a wrench.

Turn engine over several times, and 6.

returnthe to TDC-compression.

Recheck with proper feeler gauge

to make sure clearance adjust-

ment did not change as a result of

tightening the locknut. Readjust as

necessary.

Replace rocker arm cover gasket 7.

to assure proper sealing and install

cover.

Remove cylinder cover, rocker arm 1.

cover, and spark plug.

Rotate the

crankshaft while observing the piston

through the spark plug opening. When

the piston is at the top of the compres-

sion stroke (TDC), the valves can be

adjusted.

Loosen adjuster locknut so that the 2.

2.5 mm Allen socket head adjust-

ment screw can turn freely.

Insert 0.10 mm feeler gauge 3.

between valve stem tip and rocker

arm.

CAUTION!

Performing a valve adjustment

■

incorrectly may cause hard

starting and/or can damage the

engine.

If you are unfamiliar with this

■

engine or uncomfortable with

this procedure, consult with an

authorized Shindaiwa servicing

dealer.

Valve Adjustment

Fuel lter element

Hooked wire

IMPORTANT!

The valve clearance should be adjusted. It is highly recommended that this is

done by a Shindaiwa-trained service technician.