14

Maintenance (continued)

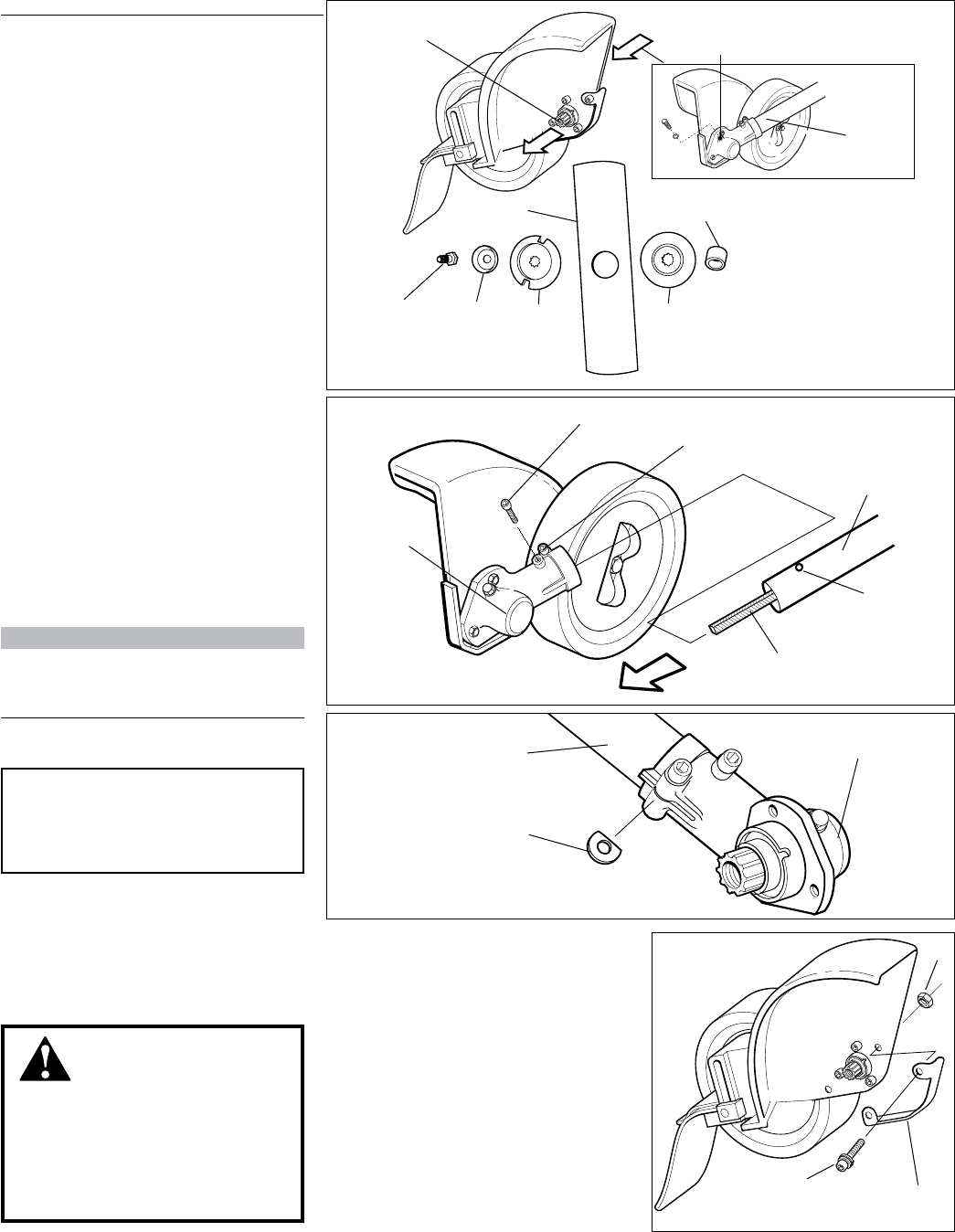

Remove the shaft bolt, bolt guard, ■

holder A, blade, holder B, and

the output shaft collar. Press new

grease into the gearcase until the

old grease has been pushed out.

Use only lithium-base grease.

Inspect the Gearcase Protector

The metal gearcase protector is installed

to protect the gearcase ange from

damage when working close to side-

walks or other abrasive surfaces, and

should be routinely inspected for dam-

age or excessive wear.

When replacing the protector, inspect to

be sure that both of the protector mount-

ing screws are rmly tightened and each

screw is locked in place with a nut as

shown.

Lubricate the Flexible Shaft

Lack of lubrication will cause rapid

wear to the exible shaft and also

to the shaft tube liner, resulting

in increased vibration and greatly

decreased service life. Remove and

lubricate the exible shaft as follows:

Loosen the gearcase clamp screw.1.

Remove the gearcase index screw.2.

Slide the gearcase and shield 3.

assembly from the shaft tube.

Pull the exible shaft from the shaft 4.

tube assembly, and clean the shaft

thoroughly in solvent.

Inspect the shaft carefully, and 5.

replace if worn or damaged. If exi-

ble shaft is worn and needs replace-

ment, liner should also be replaced.

Coat the entire length of the shaft 6.

with a premium gearcase lube and

reinstall the shaft in the shaft tube

assembly.

Insert the exible shaft into the 7.

female end of the gearcase pinion.

NOTE:

For extended shaft life, the exible

cable should be reversed end-for-end

during the reinstallation process.

New

Grease

Old

Grease

Shaft Bolt

Bolt

Guard

Holder

A

Holder

B

Output Shaft Collar

Blade

Shaft

Tube

Assembly

Gearcase lubrication

CAUTION!

The D-shaped shim washer must be

positioned with its at edge toward

the shaft tube.

Gearcase

Index Screw

Flexible shaft lubrication

Flexible shaft

Gearcase

Shaft Tube

Assembly

D-shaped shim washer

(at side toward tube)

Shaft

Tube

Assembly

Gearcase

Reinstall the gearcase onto the outer tube

Gearcase

protector

Nut

Mounting

screw

Inspect the gearcase protector

Gearcase lubrication

Shaft Index

Hole

WARNING!

Blades are not inter-

changeable between Shindaiwa

edgers and unit/brushcutter

models. Operating any unit

with a blade or attachment not

approved for the unit can be

hazardous and may cause seri-

ous injury.

50-hour Maintenance

Reinstall the gearcase onto the 8.

shaft tube assembly.

Align index screw hole in gearcase 9.

with index hole in shaft tube,

and install index screw. Tighten

securely.

Tighten the clamp screw and torque 10.

to 5.9 - 8.0 N•m (52 - 69 in•lbs).

Gearcase

Clamp Screw