* Shindaiwa One meets or exceeds these specifications and is recommended for all Shindaiwa Products

** The EPA emission compliance referred to on the emission compliance label located on the engine, indicates the number of operating hours for

which the engine has been shown to meet Federal emission requirements. Category C = 50 hours (Moderate), B = 125 hours (Intermediate) and A =

300 hours (Extended).

DESCRIPTION

Engine Code ..................S272E Engine

Dry weight, T272

(less attachment) ............6.7kg/14.7 pounds

Dry weight, T272X

(less attachment) ............6.7kg/14.8 pounds

Type ..............................2-cycle, vertical cylinder, air

cooled

Bore x Stroke .................

34 mm x 30 mm/1.3 in. x 1.2 in.

Displacement .................27.2cc/1.7 cu. in.

Maximum Power Output .1.1 kw/1.4 hp

Operating rpm Range .....4,500-9,000 rpm (min

-1

)

Transmission Type .........Automatic centrifugal clutch

through bevel gears

Fuel/Oil Ratio ................50:1 with ISO-L-EGD or JASO

FC class 2-cycle mixing oil*

Specifications T272X/C272

Fuel Tank Capacity .........670ml/22.6 ounces

Carburetion ...................Walbro diaphragm-type

Ignition .........................Fully electronic, transistor

controlled

Spark Plug ....................Champion CJ8Y

Air Cleaner Type ............Non-reversible heavy-duty

filter element

Starting Method .............

Recoil

Stopping Method ............Slide switch, grounding type

Handle ..........................Loop handle (T272)

Loop handle with barrier bar

(T272X)

EPA Emission Compliance Period** Category A

This unit comes fully assembled with

the exception of the cutting attach-

ment shield and cutting attachment.

Prior to Assembly

Before assembling, make sure you

have all the components required for

a complete unit and inspect unit and

components for any damage.

n Engine and shaft assembly

n Cutting attachment shield

n Cutting attachment

n Kit containing cutting attachment

shield bracket and hardware, this

owner's/opertor's manual and tool

kit for routine maintenance. Tool kits

vary by model and may include a hex

wrench set, spark plug/screwdriver

combination wrench and a spanner.

IMPORTANT!

The terms “left,” “left-hand,” and “LH”:

“right,” “right-hand,” and “RH”; “front” and

“rear” refer to directions as viewed by the

operator during normal operation of this

product.

5

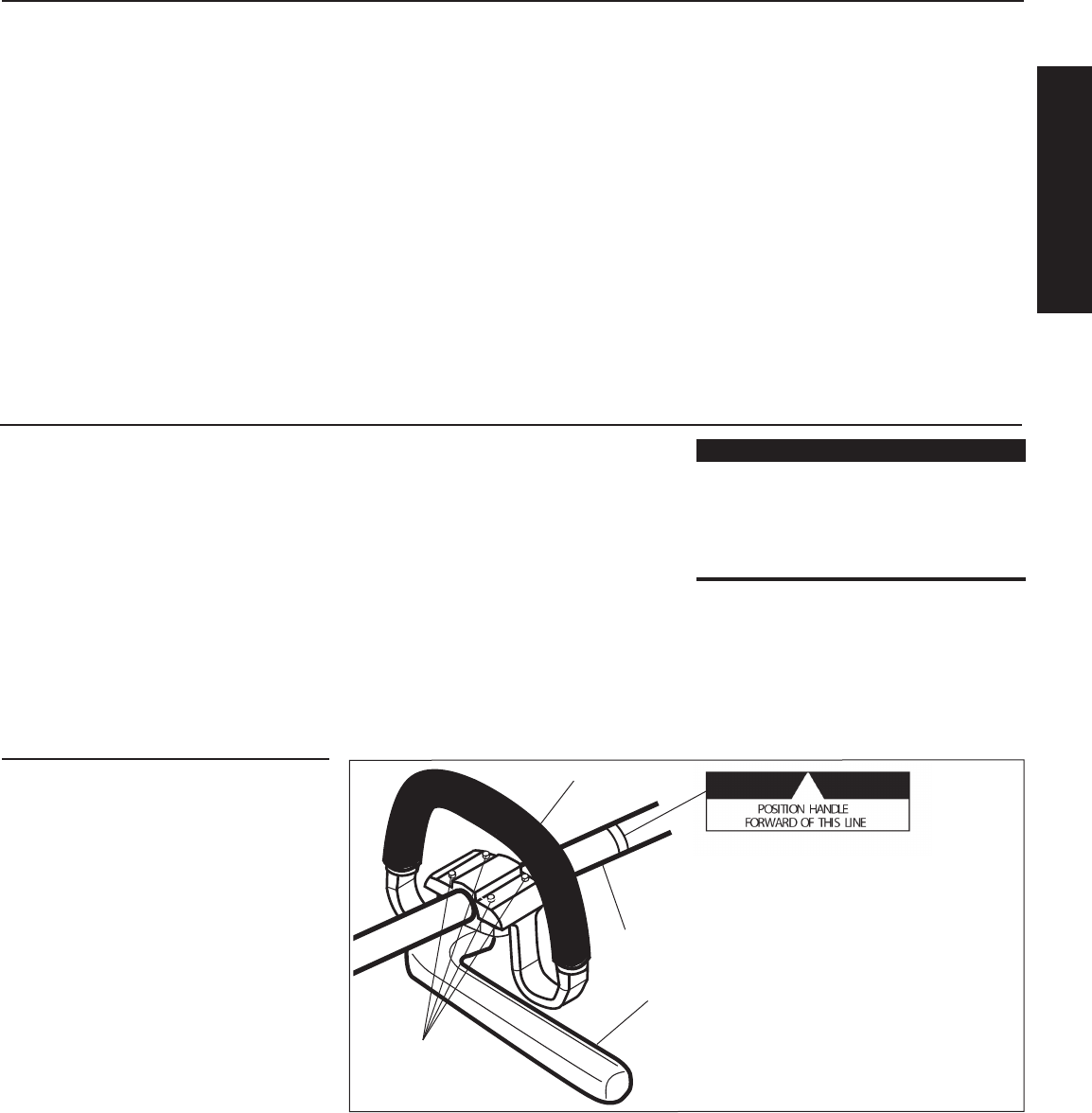

Handle T272/T272X

Assembly and Adjustments

The handle is attached to the outer tube

on the T272/T272X.

To Adjust the Handle.

1. Loosen the 4 socket-head capscrews on

the handle. See Figure 5.

2. Position the handle forward of the

Handle Positioning Label at the best

position for operator comfort (usually

about 10 inches ahead of the throttle

housing).

3. Secure the handle by alternately tight

-

ening the four socket-head cap screws

in a diagonal or “criss-cross” fashion.

Outer Tube

Handle

Handle Positioning Label

4 Socket-head Cap-

screws

Figure 5

Barrier

Bar

T272X Shown