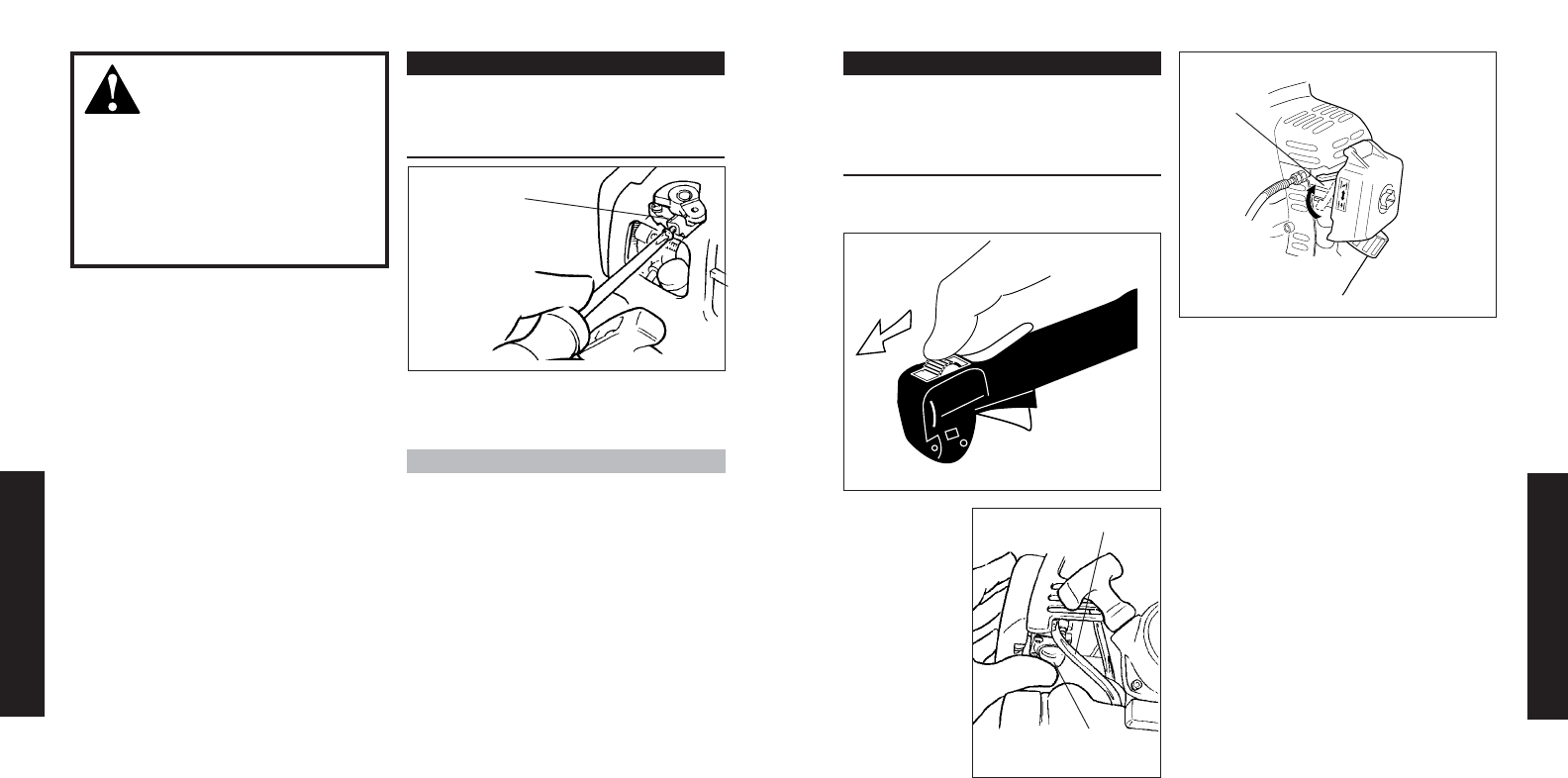

Starting A Cold Engine – Restarting After Refueling

Figure 16

IMPORTANT!

Engine ignition is controlled by a two-

position START-STOP switch mounted

on the throttle body, typically labelled

“I” for START and “O” for STOP.

A

H231_22

Primer

Bulb

Return Tube

Figure 17

Choke

Lever

Closed

3. Choke the engine by moving the

choke lever up to the “closed”

position. See Figure 18.

Before starting the engine, make sure

the cutter assembly is in the cutting

position (extended). Refer to page 13

for adjustment procedures. Never

start the engine with the cutter

assembly in the storage/transporta-

tion position.

Figure 18

AH231_23

16

2. Prime the

engine by

depressing

the carbure-

tor primer

bulb four or

five times.

See Figure

17. You

should be

able to see

fuel inside

the bulb.

Control Positions (warm engine)

1. Slide the ignition switch to the “I”

(START) position.

2. Move the choke lever down to the

“open” position.

1. Slide the ignition switch to the “I”

(START) position. See Figure 16.

OPERATION

WARNING!

The cutter attachment must never

oscillate at engine idle speed. If

the idle speed cannot be adjusted

by the procedures described here,

return the trimmer to your

Shindaiwa dealer for inspection.

Adjusting The Carburetor

Idle Adjusting

Screw

Figure 23

AH231_28

19

NOTE

This model is equipped with an EPA

approved carburetor with no mixture

adjustment.

IMPORTANT!

Use a tachometer, if one is available, to

set engine idle. Standard idle speed is:

2,750 (±250) rpm (min

-1

).

The engine must return to idle speed

whenever the throttle trigger is released.

Idle speed is adjustable and must be set

low enough to permit the engine clutch

to disengage the cutter attachment when

throttle trigger is released.

Check and Adjust Idle Speed

1. Start the engine and allow it to idle two

or three minutes, or until it warms up.

2. If the cutter attachment rotates at

engine idle, reduce idle speed by

turning the idle adjusting screw

counter-clockwise as necessary.

See Figure 23.

3. If the engine is stalling and won’t

idle, increase idle speed by turning

the idle adjustment screw clockwise.

OPERATION