Assembly; AH231

A

H231_13

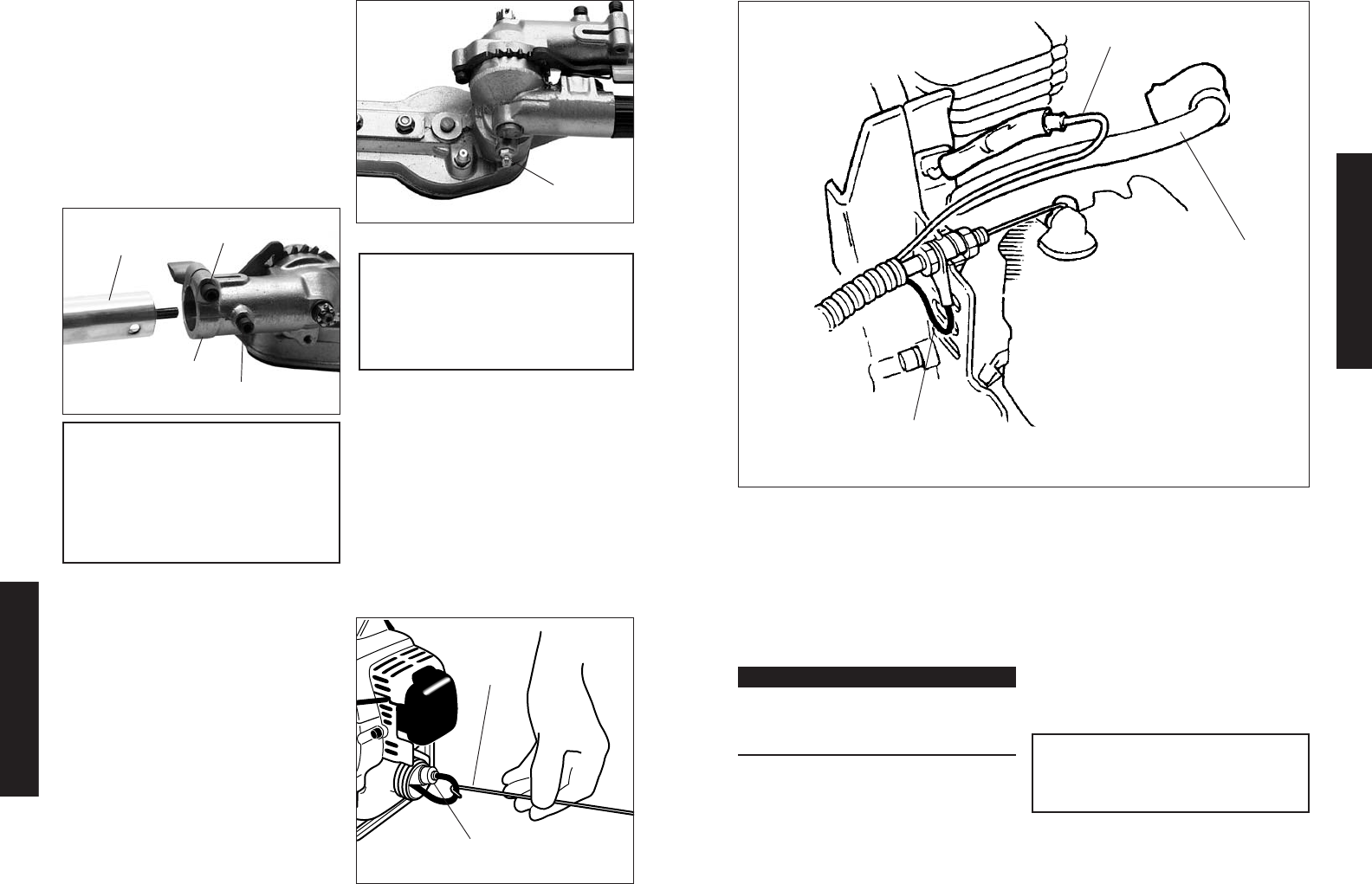

Assemble and Adjust the Throttle Cable.

1. Insert the throttle-cable housing

into the notch on the fan cover, and

clamp the black wire’s connector

between the fan cover and the cable

outer adjuster nut as shown.

2. Tighten the two throttle cable

adjuster nuts.

Black Wire

Black Wire

Connector

3. Using finger pressure only, connect

the black switch wire from the

cable tube to the red ignition wire

on the powerhead. Wire routing

must be as shown in the illustration

with the black wire located over the

spark plug wire.

4. Reinstall the cylinder cover and

tighten the three cover screws.

5. Reinstall the spark plug boot.

Figure 10

Spark Plug

Wire

12

CAUTION!

Wiring routing must not interfere

with throttle operation.

IMPORTANT!

Adjust and tighten the cable nuts to

allow approximately 1/4-inch freeplay

at the throttle trigger.

ASSEMBLY

AH231_35

AH231_34

50-Hour Maintenance

AH231_36

Every 50 hours of operation

(more frequently in dusty or

dirty conditions):

■ Remove and clean the cylinder

cover and clean dirt and debris

from the cylinder cooling fins.

■ Lubricate the gearcase. To

perform this operation, first remove

the gearcase from the outer tube as

follows (Figure 28.):

Servicing the fuel filter

Filter Element

Hooked

Wire

Figure 30

Figure 28

Outer Tube

Gearcase

a. Loosen the gearcase clamp bolt.

b. Remove the index bolt from the

gearcase.

c. Slide the gearcase out of the tube.

Using a grease gun, pump lithium-

base grease (about 10 grams) into

the grease fitting on the gearcase

until you see old grease being

purged from the gearcase (Figure

29). Purged grease will be visible in

the outer tube cavity. Clean up

excess grease, then reassemble the

gearcase onto the outer tube. Make

sure the index bolt fits into the hole

on the outer tube. Securely tighten

both bolts.

Gearcase

Clamp Bolt

Index Bolt

Figure 29

Gearcase

Grease

Fitting

CAUTION!

Make sure you do not pierce the

fuel line with the end of the

hooked wire. The line is delicate

and can be damaged easily.

■ Use a hooked wire to extract the

fuel filter from inside the fuel tank

(Figure 30). Inspect the fuel filter

element. If it shows signs of

contamination from debris, replace

it with a genuine Shindaiwa replace-

ment fuel filter element. Before

reinstalling the filter, inspect the

fuel line. If you discover damage or

deterioration, the unit should be

removed from service until it can be

inspected by a Shindaiwa-trained

service technician.

CAUTION!

Do not remove the D-shaped shim

washer from the gearcase clamp!

The shim washer prevents

damage from overtightening the

tube clamp screw.

23

MAINTENANCE