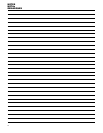

Cable adjustor

Locknut

Throttle cable

Throttle lever free play

5-7 mm (0.2-

0.275”)

Locknut

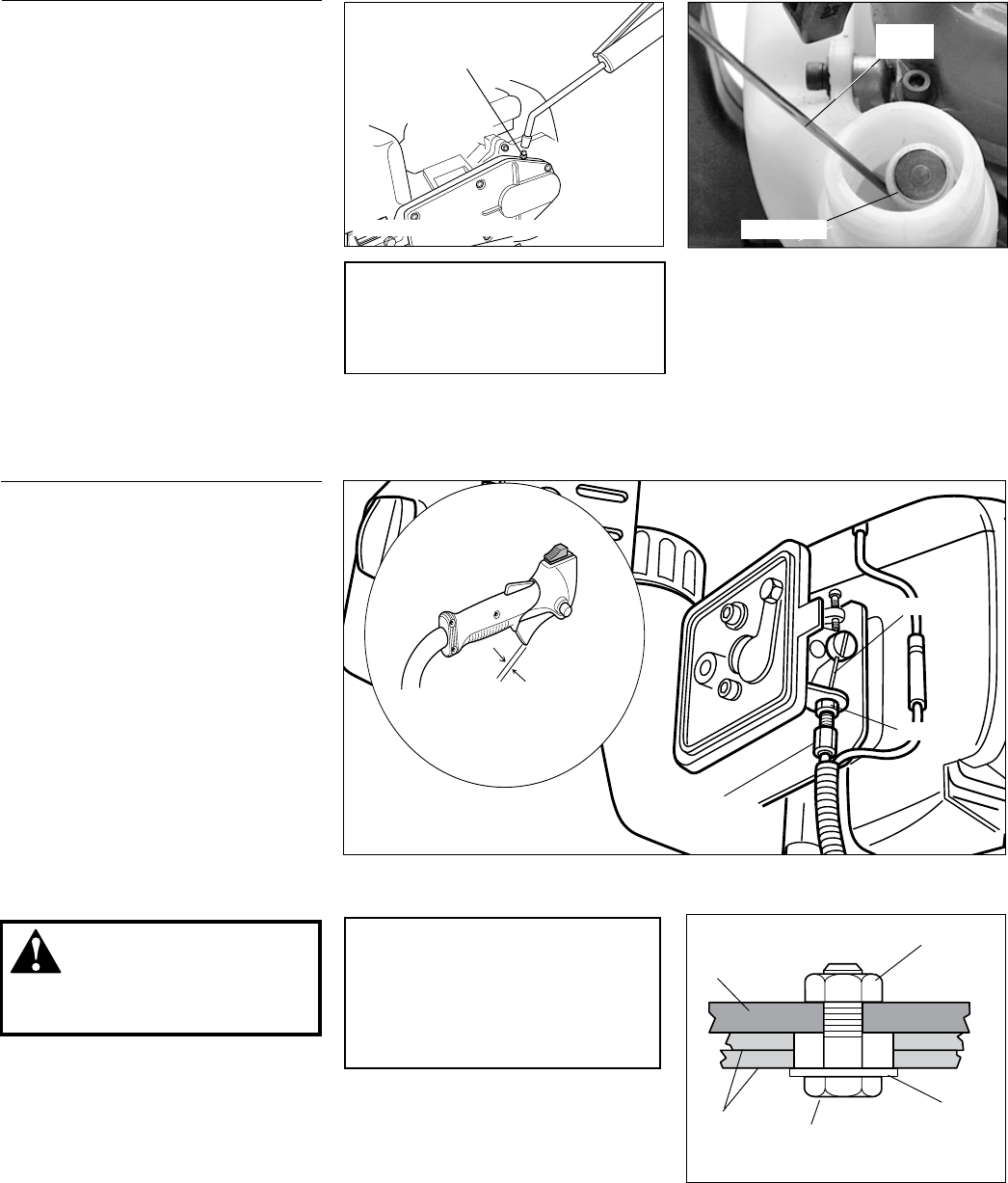

Guide Bar

Cutter

Blades

Shoulder Bolt

Washer

(should turn

freely)

Adjusting cutter blades

)XHO¿OWHU

Hooked

wire

BOTTOM

VIEW

Gearcase grease

¿WWLQJ

50 hour maintenance

11

50 hour maintenance

CAUTION!

Make sure you do not pierce the fuel line

with the end of the hooked wire. The line

is delicate and can be damaged easily.

Every 50 hours of operation (more

often in dusty or dirty conditions):

Remove and clean the cylinder cover and

Ŷ

clean grass and dirt from the cylinder fins.

Gearcase lubrication

Remove the gearcase cover, and use solvent

and a soft brush to remove all old grease

from the gearcase. To refill, hand-pack the

gearcase with approximately 40–50 grams

of high quality lithium-based grease (50–

70% of capacity). DO NOT OVERFILL!

Remove and replace fuel filter element

Use a wire hook to extract the fuel filter Ŷ

from inside the fuel tank. Inspect the

fuel filter element. If it shows signs of

contamination from debris, replace it

with a genuine Shindaiwa replacement

fuel filter element.

Before reinstalling the filter, inspect the

fuel line. If you discover damage or dete-

rioration, the unit should be removed

from service unitl it can be inspected by

a Swisher-trained service technician.

Throttle free play adjustment

If the unit does not return to idle speed

or doesen’t reach full rpm, the throttle

lever free play may need to be adjusted as

follows:

Measure free play at the end of the 1. throt-

tle lever. Throttle lever free play should

be approximately 5-7 mm (0.2-0.275”).

If adjustment is necessary, remove the 2.

air cleaner cover by loosening the two

thumbscrews. Loosen the cable adjuster

lock nut and turn the cable adjustment fit-

ting in or out until throttle lever free play

is approximately 5-7 mm (0.2-0.275”).

Replace the air cleaner cover, and 3.

tighten the cover retaining screws

securely.

Cutting performance of your machine

depends a great deal on proper cutter

blade adjustment. Properly adjusted

blades will oscillate freely yet help pre-

vent binding of cut material between

blades. Adjust blades as follows:

Loosen all blade locknuts at least one 1.

full turn.

Tighten each blade shoulder bolt 2.

firmly, and then loosen the shoulder

bolts 1/4 to 1/2 turn.

Cutter blade adjustment

Working from the gearcase end, lock 3.

each bolt in place by firmly tightening

its locknut while preventing the shoul-

der bolt from turning.

When shoulder bolt adjustment is cor-

rect, there should be a gap of 0.25–0.50

mm between the cutter blades and the

flat washers, and the flat washer beneath

each bolt head should turn freely.

WARNING!

The cutter blades are very

sharp! Always wear gloves when

working around the cutter assembly.

CAUTION!

Operating the trimmer with worn or

improperly adjusted cutters will reduce

cutter performance and may also dam-

age your machine. Never operate the

machine with damaged or worn cutters.