6

DESCRIPTION

Model ....................................................................................................................... 357

Engine Type ................................................................ 2 cycle air cooled gas engine

Displacement .............................................................................. 35.5 cc (2.17 cu.in.)

Fuel ..................... Gasoline-Oil Mixture—50:1 with Shindaiwa 2-cycle Mixing Oil

Carburetor......................................................... Diaphragm (WALBRO Model WT)

Ignition ...................................................... All transistor electronic ignition system

Spark Plug .......................................................................................... Champion CJ6Y

................................................................. For EMC compliance use NGK BPMR7A

Starting ......................................................................................................Auto-rewind

Stopping............................................................................Grounding (toggle switch)

Power transmission......................................................Automatic centrifugal clutch

Chain lubrication ........................................................ Automatic clutch-driven oiler

Chain..................................................................................... 3/8" pitch, gauge 0.050"

Chain oil ................Shindaiwa brand premium Bar and Chain Oil (or equivalent)

Fuel tank capacity ............................................................................... 265 ml (9.0 oz)

Oil tank capacity .................................................................................. 210 ml (7.1 oz)

Front/Rear Handles.............................................. Special anti-vibration mountings

Cooling system ........................................................................................... Forced air

Safety devices .......... Front guard, throttle lock, chain catcher and inertial brake

Weight (less bar and chain)............................................................... 4.2 kg (9.3 lbs)

■ Screwdriver

■ Spark plug/13 mm socket wrench

■ 4 mm hex wrench

■ 5 mm hex wrench

Do not make unauthorized modifi-

cations to this saw, guide bar, or

chain!

Part Number

Size Chain Bar

12-inch Oregon 91 VG-45X 36120-12

14-inch Oregon 91 VG-53X 36349-14

16-inch Oregon 91 VG-57X 36450-16

RECOMMENDED BAR AND CHAIN COMBINATIONS

Specifications

WARNING!

Replacement chain for

this saw must meet applicable

ANSI B175.1-2000 kickback

performance requirements,

and/or be designated as “low

kickback chain” per ANSI

B175.1-2000 standards.

WARNING!

Tools Included

35

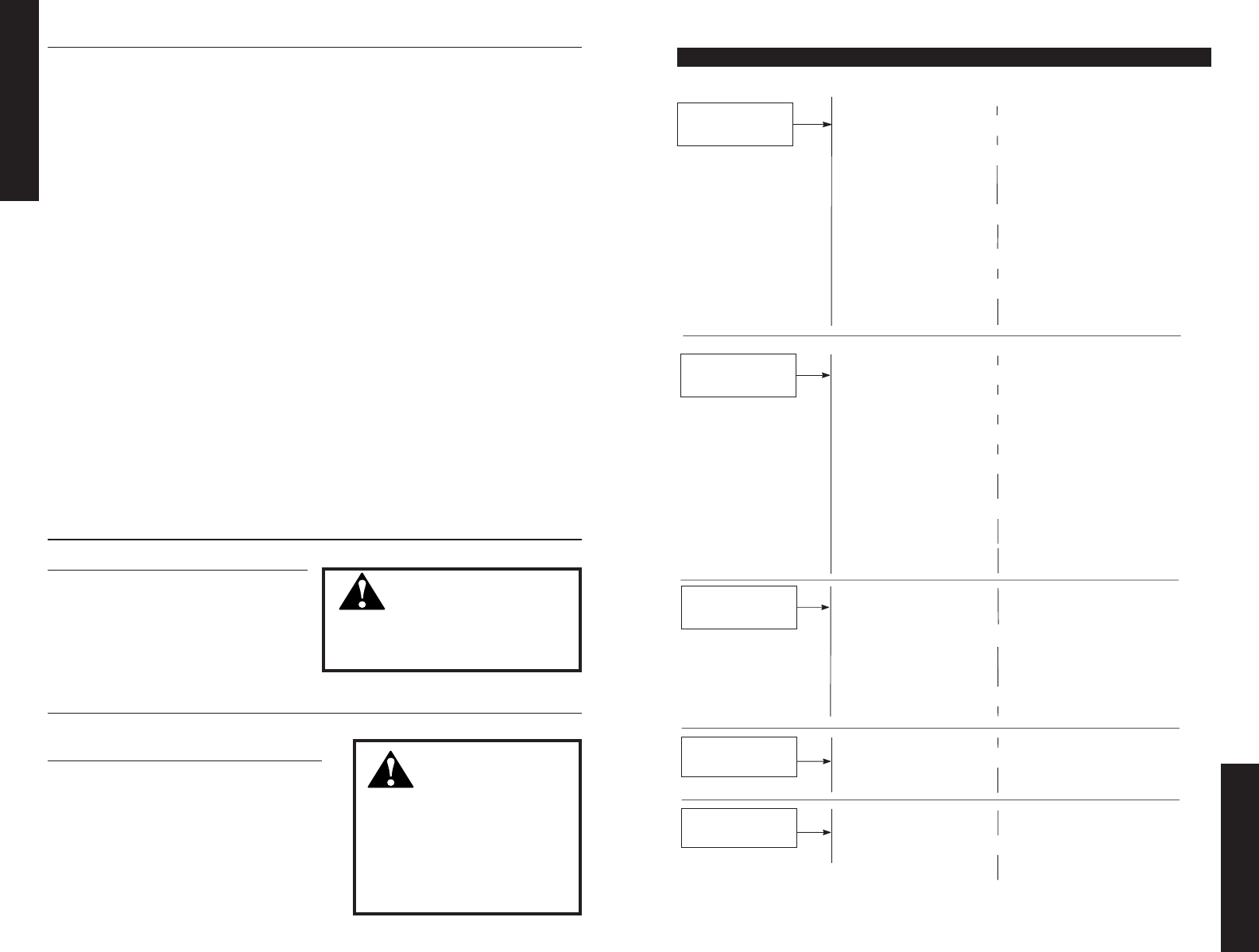

TROUBLESHOOTING

ADDITIONAL PROBLEMS

Poor

acceleration.

Clogged air cleaner.

Clogged fuel filter.

Chain brake engaged

Carburetor mixture

too rich or too lean.

Idle speed set too low.

Spark arrester clogged

Clean the air cleaner element.

Replace the fuel filter.

Inspect and/or test brake.

Consult with an authorized

servicing dealer.

Adjust carburetor.

Adjust: 2,600-3,000 RPM (min

-1

)

Clean spark arrester.

(See page 29).

Symptom Possible Cause

Remedy

Engine stops

abruptly.

Switch turned off.

Fuel tank empty.

Clogged fuel filter.

Water in the fuel.

Shorted spark plug or

loose terminal.

Ignition failure.

Piston seizure.

Set the switch to “I” (ON), re-start.

Refuel.

Clean or replace filter as required.

Drain; replace with clean fuel.

Clean and replace spark plug.

Tighten the terminal.

Consult with an authorized

servicing dealer.

Consult with an authorized

servicing dealer.

Engine difficult

to shut off.

Ground (stop) wire is

disconnected, or switch

is defective.

Overheating due to

incorrect spark plug.

Overheated engine.

Test and replace as required.

Correct plug:

Champion CJ6Y. For EMC

compliance use NGK BPMR 7A

Idle engine until cool.

Chain rotates

at idle speed.

Engine idle too high.

Broken clutch spring

or shoe.

Set idle: 2,600-3,000 RPM (min

-1

).

Replace spring/shoes as

required.

Excessive

vibration.

Worn or damaged

sprocket, chain or bar.

Bent crankshaft.

Inspect and replace chain

components as required.

Consult with an authorized

servicing dealer.

Troubleshooting