13

OPERATION

35710

WARNING!

Inspect chain tension

often during operation,

especially when breaking in a new

chain. A loose saw chain can

unexpectedly jump the guide bar

during operation, possibly causing

serious personal injury!

IMPORTANT!

Proper chain adjustment is essential

for maximum performance, chain life,

and operator safety. Always inspect

chain tension before operating the saw!

NOTE:

For longest chain life, place new or

replacement chain loops in oil and soak

overnight before installation.

8. Place the saw on a flat surface, and

lift the bar nose slightly.

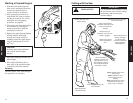

9. To adjust chain tension:

■ turn the chain tension screw

clockwise to tighten the chain.

■ turn the chain tension adjuster

counter-clockwise to loosen the

chain.

57707

Check the gap between chain side

plates and the bar rail

Chain

Adjusting

Screw

Turn clockwise to tighten

the chain (extend the

guide bar)

■ Hard-nose Guide Bar Gently lift

the chain at about mid-bar. Tension

is correct when there is a gap of

3–3.5 mm (about 0.125") between

the chain side plates and the bar

rail.

■ Sprocket-nose Guide Bar The

chain should be adjusted slightly

tighter than on a hard-nose bar, but

must still pull freely around the bar.

10.Tighten both bar nuts securely,

making sure chain adjustment is

correct for the type of bar installed.

Adjusting Chain Tension in the

Field Stop the saw, loosen both bar

nuts about 1 turn each, then repeat

Steps 8 through 10 (above). Never

operate the saw when the chain is

loose!

Installing and Adjusting the Guide Bar and Saw Chain

28

35720

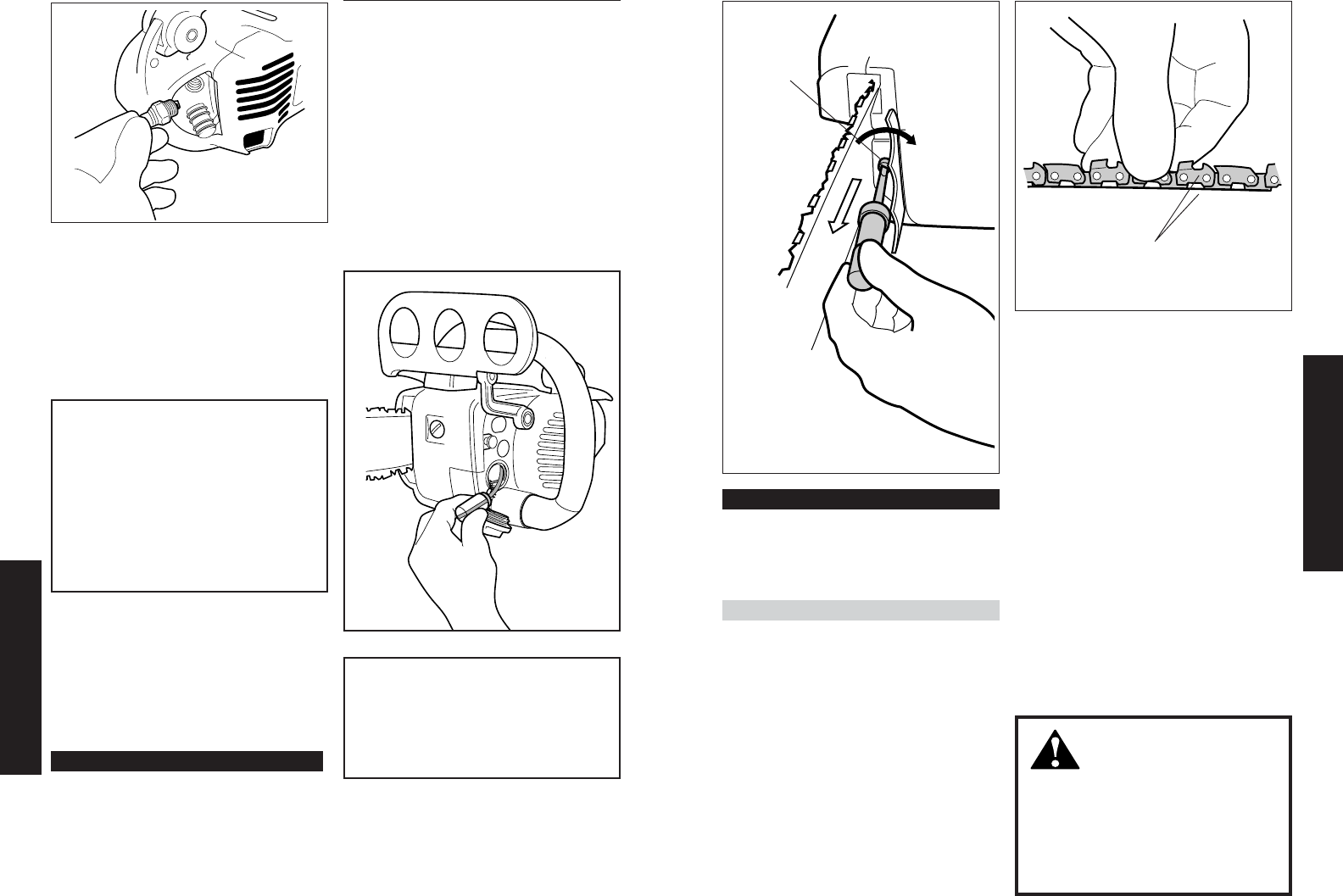

40/50 Hour Maintenance

■ Replace the spark plug with a

Champion CJ6Y (or equivalent),

gapped to 0.024" (0.6 mm). For EMC

compliance use NGK BPMR 7A.

■ Extract the fuel filter from inside the

fuel tank. Remove and wash both

filter elements in clean fuel. If you

discover damage or deterioration to

the fuel lines or other fuel system

components, remove the saw from

service until it can be inspected by a

Shindaiwa-trained service technician.

CAUTION!

The fuel line can be punctured or

torn by careless handling! Never

use sharp or jagged-edged tools to

extract the fuel line.

35719

10/15 Hour Maintenance

■ Remove and clean the spark plug.

Adjust the spark plug gap to 0.024"

(0.6 mm), and reinstall. If a torque

wrench is available, torque the plug

to 148–165 in.-lbs. Replace a

damaged or visibly worn plug with

a Champion CJ6Y or For EMC

compliance use NGK BPMR 7A.

CAUTION!

Incorrect spark plug installation

can result in serious engine

damage!

Never allow chips or other

debris to enter the cylinder bore!

Before removing the spark plug,

thoroughly clean the spark plug

and cylinder head area!

■ Remove the guide bar and chain.

Carefully inspect the drive sprocket

for wear or damage, and replace if

needed. Inspect the guide bar

grooves and tip for wear or dam-

age, and repair or replace compo-

nents as required.

IMPORTANT!

Always replace the drive sprocket and

cutting chain loop as a set! For

economy, rotate the same 2 or 3

chains daily. When these chains are

worn out, replace both the chains and

the sprocket at the same time.

MAINTENANCE