SHARK SSG • 8.914-337.0 / 97-6134 • Rev. 8/07

13

PRESSURE WASHER

OPERATOR’S MANUAL

MAINTENANCE

Step 4 After circulating solution, flush the entire

system with fresh water. Clean out float tank

and then reinstall wand assembly to spray

gun.

Removal of Soot from Heating Coil:

In the heating process, fuel residue in the form of soot

deposits may develop between the heating coil pipe,

and block air flow which will affect burner combustion.

When soot has been detected on visual observation,

the soot on the coil must be washed off after following

the coil removal steps (See Coil Removal section).

Rupture Disk:

If pressure from pump or thermal expansion should

exceed safe limits, the rupture disk will burst allowing

high pressure to be discharged through hose to ground.

When disk ruptures it will need to be replaced.

Fuel:

Use clean fuel oil that is not contaminated with water

and debris. Replace fuel filter and drain tank every 100

hours of operation.

Use No.1 or No 2 Heating Oil (ASTM D306) only.

NEVER use gasoline in your burner fuel tank. Gasoline

is more combustible than fuel oil and could result in a

serious explosion. NEVER use crankcase or waste oil

in your burner. Fuel unit malfunction could result from

contamination.

Fuel Control System:

This machine utilizes a fuel solenoid valve located on

the fuel pump to control the flow of fuel to the combus-

tion chamber. The solenoid, which is normally closed,

is activated by a flow switch when water flows through

it. When the operator releases the trigger on the spray

gun, the flow of water through the flow switch stops,

turning off the electrical current to the fuel solenoid.

The solenoid then closes, shutting off the supply of

fuel to the combustion chamber. Controlling the flow

of fuel in this way gives an instantaneous burn-or-no-

burn situation, thereby eliminating high and low water

temperatures and the combustion smoke normally

associated with machines incorporating a spray gun.

Periodic inspection, to insure that the fuel solenoid

valve functions properly, is recommended. This can

be done by operating the machine and checking to

see that the burner is not firing when the spray gun is

in the OFF position.

Fuel Pressure Adjustment:

To control water temperature, adjust fuel pressure

by turning the regulating pressure adjusting screw

clockwise to increase, counterclockwise to decrease.

Do not exceed 200 psi. NOTE: When changing fuel

pump, a bypass plug must be installed in return port

or fuel pump will not prime.

Burner Nozzle:

Keep the tip free of surface deposits by wiping it with

a clean, solvent saturated cloth, being careful not to

plug or enlarge the nozzle. For maximum efficiency,

replace the nozzle each season.

Air Adjustment:

Machines are preset and performance tested at the

factory - elevation 100'. A one-time initial correction for

your location will pay off in economy, performance, and

extended service life. If a smoky or eye-burning exhaust

is being emitted from the stack, two things should be

checked. First, check the fuel to be certain that kerosene

or No. 1 home heating fuel is being used. Next, check

the air adjustment on the burner.

To adjust, start machine and turn burner ON. Loosen two

locking screws found in the air shutter openings (refer

to illustration) and close air shutter until black smoke

appears from burner exhaust vent. Note air band posi-

tion. Next, slowly open the air shutter until white smoke

just starts to appear. Turn air shutter halfway back to the

black smoke position previously noted. Tighten locking

screws.

If the desired position cannot be obtained using only the

air shutter, lock the air shutter in as close a position as

can be obtained, then repeat the above procedure on

the air band setting.

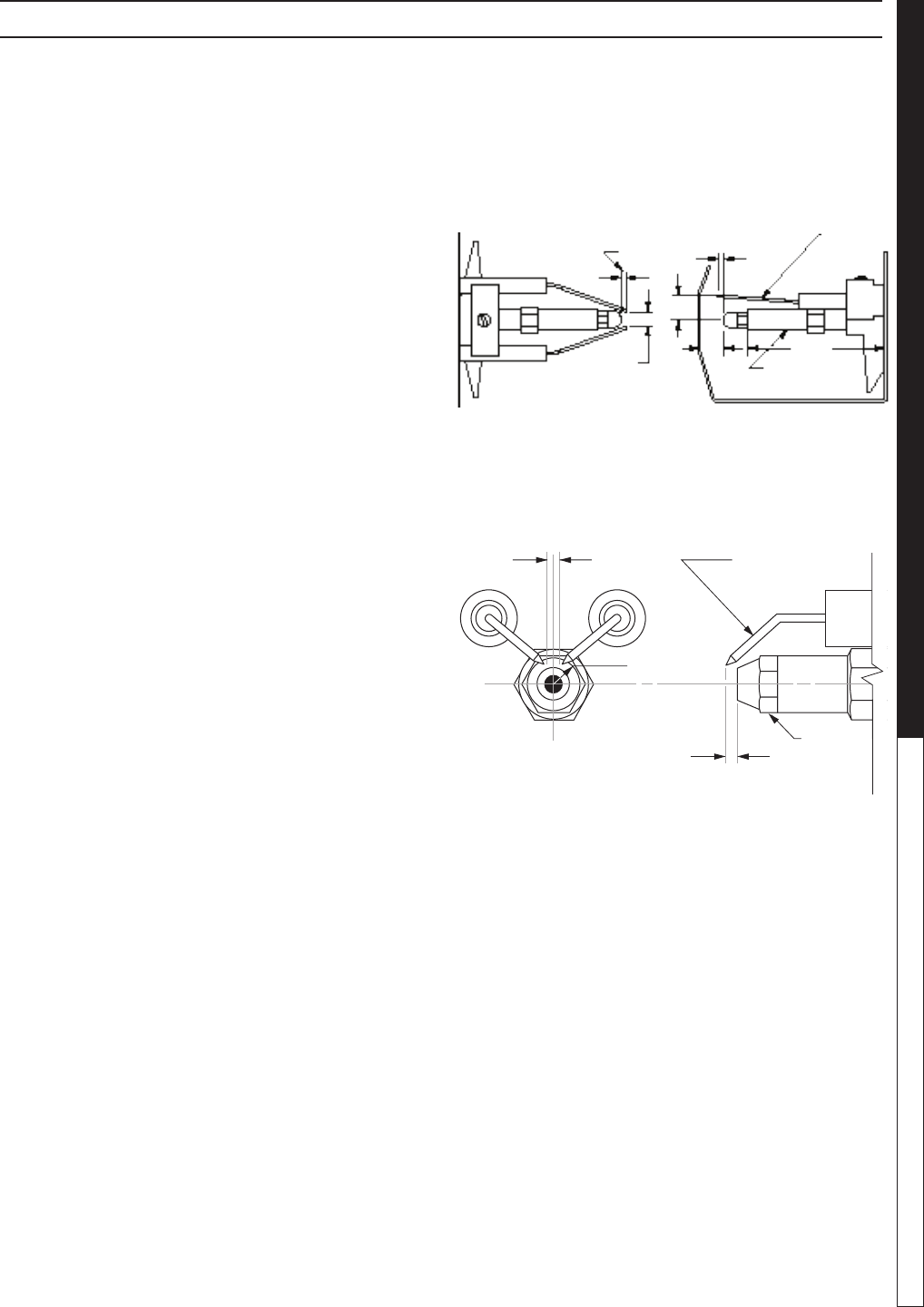

Electrode Setting: Wayne

1/16"

5/16"

Nozzle

5/32"

Elec-

Top Side

1/8"

1/8"

3/8"

1/2"

Top Side

Nozzle

2-7/8"

Periodically Check Wiring Connections. If Nec-

Elec-

Electrode Setting: Beckett