SHARK SSG • 97-6134 • REV. 7/05a

11

PRESSURE WASHER

OPERATOR’S MANUAL

SHUTTING DOWN AND CLEAN-UP

STORAGE

CAUTION: Always store your pressure washer in a

location where the temperature will not fall below

32°F (0°C). The pump in this machine is susceptible

to permanent damage if frozen. FREEZE DAMAGE

IS NOT COVERED BY WARRANTY.

1. Stop the pressure washer, squeeze spray gun trig-

ger to release pressure.

2. Detach water supply hose and high pressure hose.

3. Turn on the machine for a few seconds, until re-

maining water exits. Turn engine off immediately.

4. Drain the gas and oil from the engine.

5. Do not allow high pressure hose to become kinked.

6. Store the machine and accessories in a room which

does not reach freezing temperatures.

CAUTION: Failure to follow the above directions will

result in damage to your pressure washer.

When the pressure washer is not being operated or is being

stored for more than one month, follow these instructions:

1. Replenish engine oil to upper level.

2. Drain gasoline from fuel tank, fuel line, fuel valve

and carburetor.

3. Pour about one teaspoon of engine oil through the

spark plug hole, pull the starter grip several times

and replace the plug. Then pull the starter grip slowly

until you feel increased pressure which indicates

the piston is on its compression stroke and leave it

in that position. This closes both the intake and ex-

haust valves to prevent rusting of cylinder.

4. Cover the pressure washer and store in a clean, dry

place that is well ventilated away from open flame or

sparks. NOTE: The use of a fuel additive, such as

STA-BIL

®

, or an equivalent, will minimize the formu-

lation of fuel deposits during shortage. Such addi-

tives may be added to the gasoline in the fuel tank of

the engine, or to the gasoline in a storage container.

After Extended Storage

CAUTION: Prior to restarting, thaw out any

possible ice from pressure washer hoses,

spray gun or wand.

Engine Maintenance

During the winter months, rare atmospheric conditions

may develop which will cause an icing condition in the

carburetor. If this develops, the engine may run rough,

lose power and may stall. This temporary condition can

be overcome by deflecting some of the hot air from the

engine over the carburetor area. NOTE: Refer to the

engine manufacturer's manual for service and mainte-

nance of the engine.

STEP 1: Remove detergent suction

tube from container and insert into

one gallon of fresh water. Open de-

tergent metering valve. Pull trigger

on spray gun and siphon water for

one minute. Close detergent valve.

STEP 2: Turn off the engine. STEP 3: Turn off water

supply.

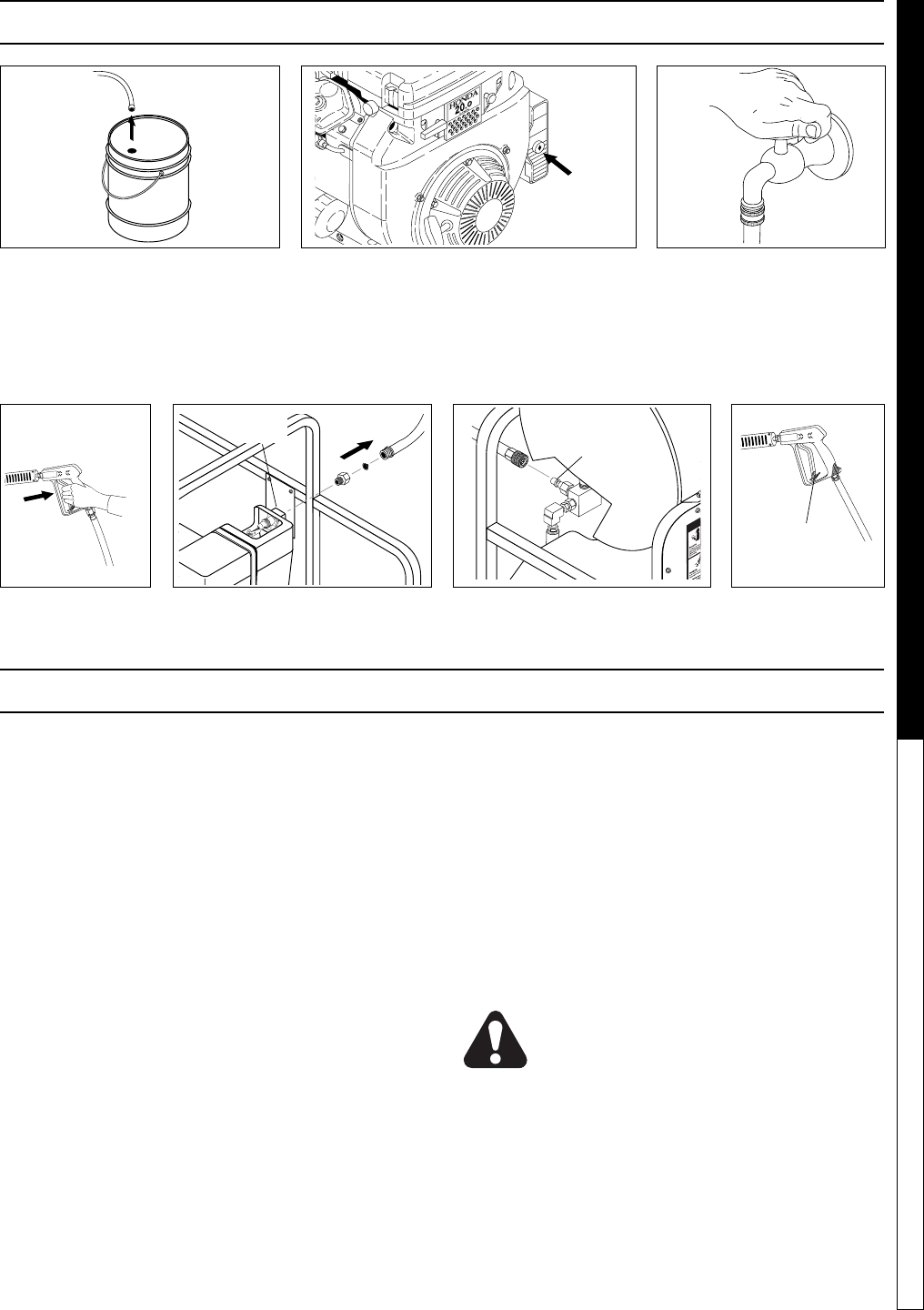

STEP 5: Disconnect the garden

hose from the water inlet on the

machine.

STEP 6: Disconnect the high

pressure hose from high pres-

sure outlet.

STEP 7: Engage

the spray gun safety

lock.

STEP 4: Press trig-

ger to release water

pressure.

Engine

On-Off

Switch

High

Pressure

Outlet

Safety

Latch

Water

Inlet