OPERATION

FR240-FR162 01/11 Operation Section 4-16

© 2011 Alamo Group Inc.

OPERATION

6.1 Driveline Length Check

When fitting the mower to the tractor , the telescoping driveline must be inspected to ensure that at its most

compressed position, the shafts do not “bottom out”, and when at its farthest extended postion, there is

sufficient engagement between the profiles to operate safely. At its shortest length, there must be at least at 1”

clearance between each profile end and opposite profile universal joint. At its farthest operating extension, a

minimum profile engagement of 6” must be maintained.

Before operating the Implement, check to make sure the Implement input driveline will not

bottom out or become disengaged. Bottoming out occurs when the inner shaft penetrates

the outer housing until the assembly becomes solid-it can shorten no more. Bottoming out

can cause serious damage to the Tractor PTO by pushing the PTO into the Tractor and

through the support bearings or downward onto the PTO shaft, breaking it off. A broken

driveline can cause personal injury.

(S3PT-18)

“Bottoming Out” Check Procedure

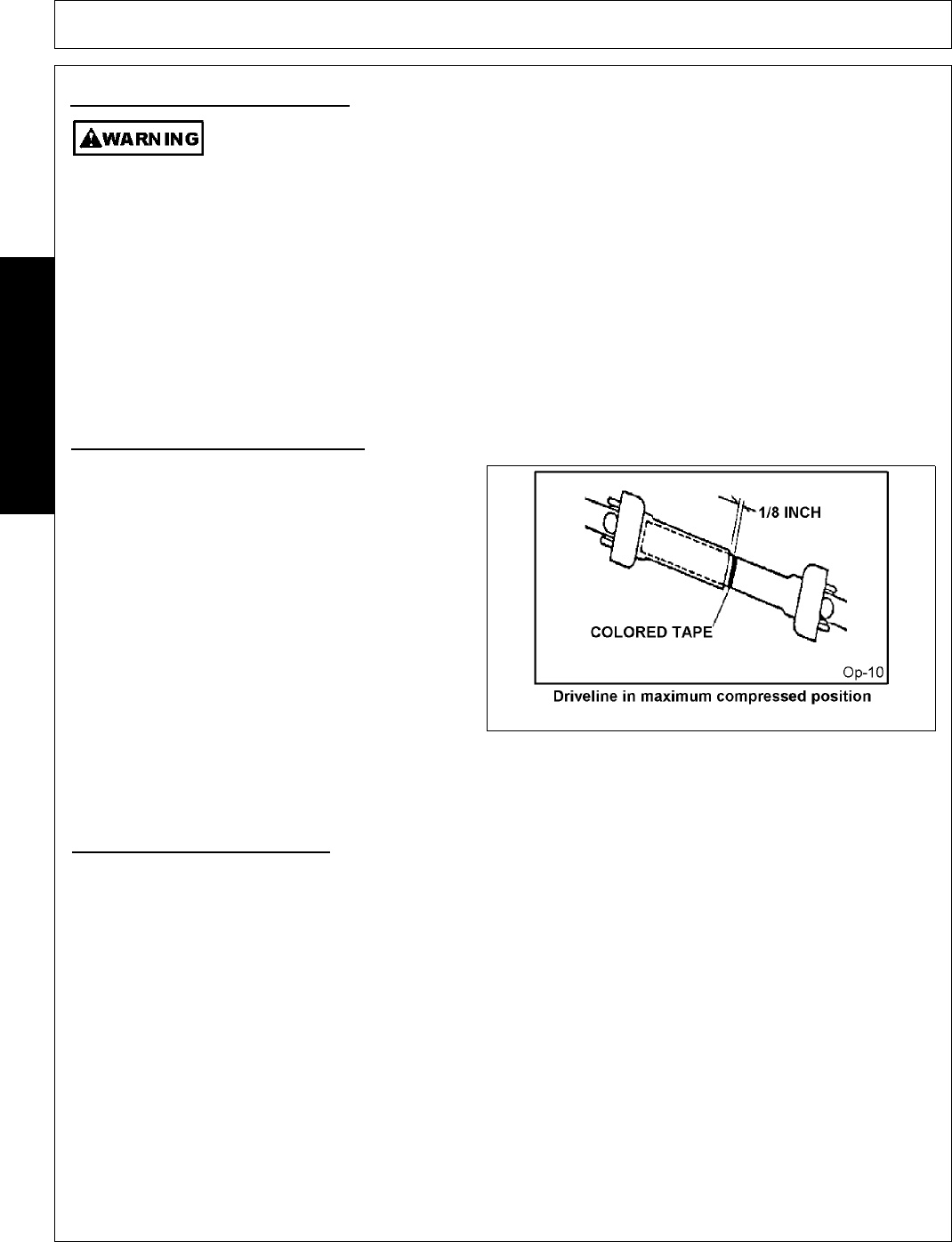

• Disconnect driveline from the tractor and slide

the profiles together until fully compressed.

• Place a mark on the inner shield 1/8” from the

end of the outer shield and reattach the

driveline to the PTO shaft.

• With the PTO NOT TURNING, slowly drive the

tractor with mower attached through the

sharpest turn possible and watch shaft

movement. With the PTO NOT TURNING,

slowly drive the tractor with the mower attached

through the most severe terrain conditions

expected and watch shaft movement.

• If the distance between the mark and the outer

shield becomes less than 2” at any point there is a potential problem bottoming out the driveline and the

driveline should be replaced with shorter driveline. Contact your local dealer or Technical Service for

Engagement Check Procedure

• With the driveline attached, position the mower to the point where the telescoping driveline is at its maximum

extension. Completely shut down the tractor and secure in position.

• Mark the inner driveline shield 1/8” from the end of the outer shield.

• Disconnect the driveline from the tractor and separate the two driveline halves.

• Measure the distance from the mark to the end of the inner profile. This length is the amount the driveline profiles were

engaged.

• If the engaged length is less than 6”, the shaft is considered too short and should be replaced with a longer shaft.

Consult an authorized dealer to purchase the required driveline length.

NOTE: If the driveline cannot be shortened and still maintain the required profile engagement, the operator must be made

aware of terrain conditions and avoid situations which pose a potential problem to avoid damaging the driveline or move

drawbar to 16” or 20” position for required clearance. OPS-R-0005_O