MAINTENANCE

FR240-FR162 01/11 Maintenance Section 5-16

©2011 Alamo Group

MAINTENANCE

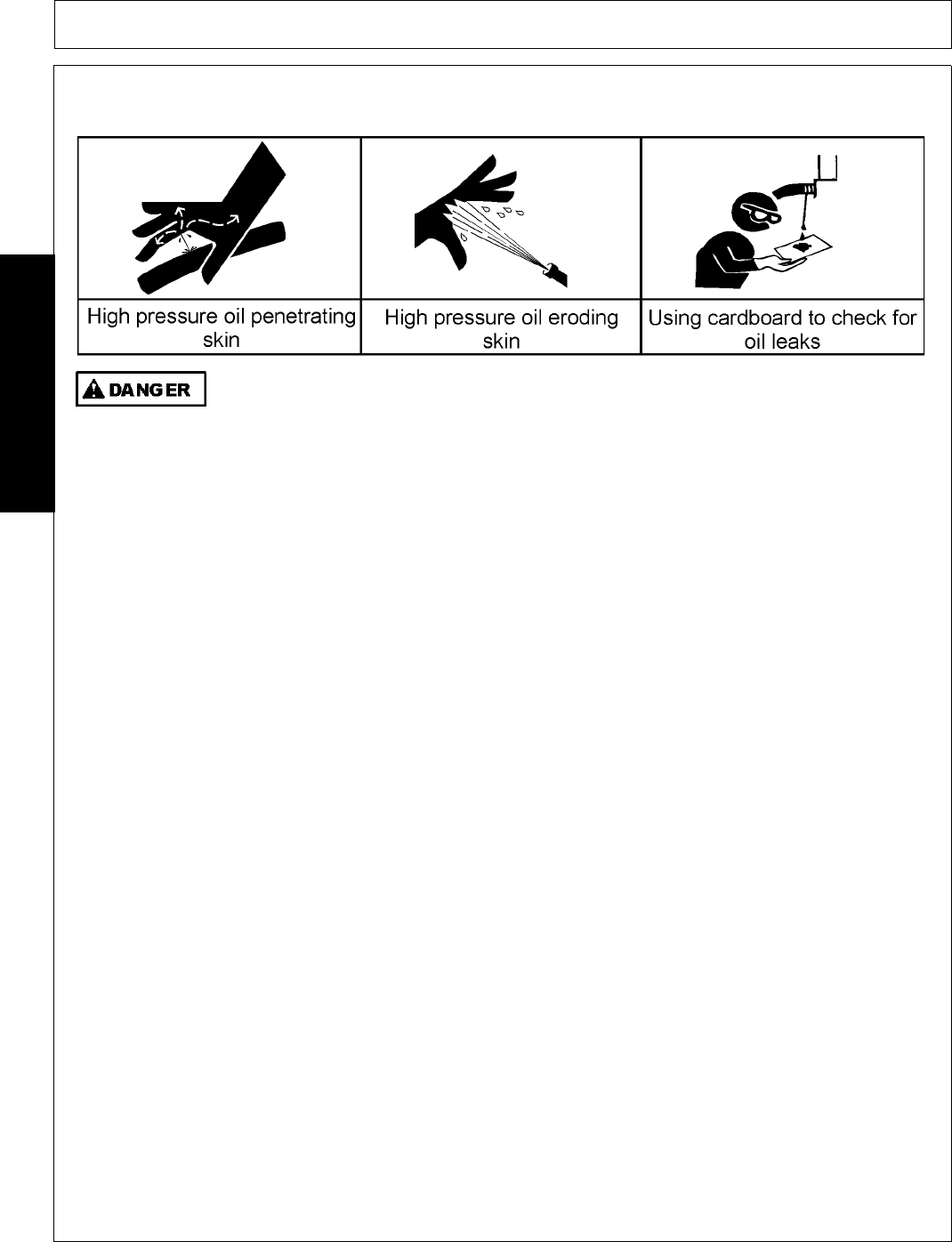

HIGH PRESSURE OIL LEAK HAZARD

HYDRAULIC HOSES

Replace pinched and broken Hydraulic Hoses at once. Tighten any Hydraulic Fitting with fluid leaking from it. If

fluid still leaks, loosen the fitting, apply a pipe thread compound to the threads and tighten. Care must be

exercised when tightening Hydraulic Fittings. Too much tightening can cause the fittings to crack and require

replacement fittings.

Although a small amount of oil will be present from bleeding at all Hydraulic Fittings, significant amounts of oil

leaking around the Breather Plug on the Cylinder indicates that the seal in the Cylinder is worn out. Replace

the seals in the Cylinder immediately before the Cylinder is damaged or too much hydraulic fluid is lost.

MAXIMUM ALLOWABLE OPERATING OIL TEMPERATURE

Do not operate this implement if the tractor hydraulic oil temperature exceeds 200°F

TO AVOID SERIOUS INJURY OR DEATH FROM HIGH PRESSURE HYDRAULIC OIL LEAKS

PENERATING SKIN:

• DO NOT OPERATE equipment with oil or fuel leaks.

• KEEP all hydraulic hoses, lines and connections in GOOD CONDITION and TIGHT before applying system

pressure.

• RELIEVE HYDRAULIC PRESSURE before disconnecting lines or working on the system.

•REMOVE and replace hose if you suspect it leaks. Have dealer test it for leaks.

HIGH PRESSURE FLUID LEAKS CAN BE INVISIBLE.

WHEN CHECKING FOR HYDRAULIC LEAKS AND WORKING AROUND HYDRAULIC SYSTEMS:

• ALWAYS WEAR safety glasses and impenetrable gloves.

•USE paper or cardboard to search for leaks.

•DO NOT USE hands or body parts to search for leak.

• KEEP hands and body AWAY from pin holes and nozzles ejecting hydraulic fluid.

• Hydraulic fluid may cause gangrene if not surgically removed immediately by a doctor familiar with this form of injury.

PN HP01