16

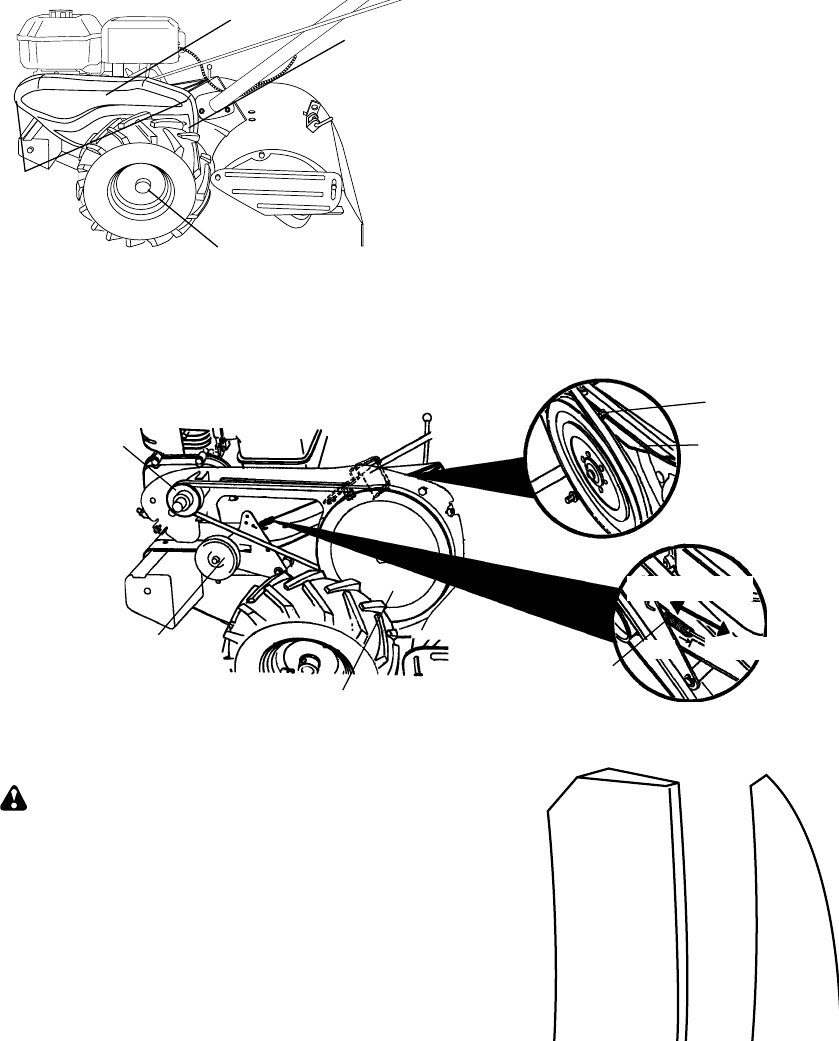

New Tine

Worn Tine

TINE REPLACEMENT

CAUTION: Tines are sharp. Wear

gloves or oth er protection when han dling

tines.

A badly worn tine causes your tiller to

work hard er and dig more shallow. Most

im por tant, worn tines cannot chop and

shred or gan ic mat ter as effectively nor

bury it as deep ly as good tines. A tine this

worn needs to be re placed.

Cable Clip Screw

Drive Control Cable

Extension Spring

Engine Pulley

Idler Pulley

Transmission Pulley

Hairpin Clip and Clevis Pin

Screws

Hex

Nut and

Wash er

(Lo cat ed

Behind

Tire)

Belt Guard

Less Tension

More Tension

5/8"

TO REPLACE GROUND DRIVE BELT

1. Remove belt guard as described in “TO

RE MOVE BELT GUARD”.

TO REMOVE BELT GUARD

NOTE: For ease of removal, remove hair-

pin clip and clevis pin from left wheel. Pull

wheel out from tiller about 1 inch.

1. Re move two (2) screws from side of

belt guard.

2. Remove hex nut and washer from

bot tom of belt guard (located behind

wheel).

3. Pull belt guard out and away from unit.

4. Replace belt guard by reversing above

procedure.

2. Remove old belt by slipping off engine

pulley fi rst then remove from trans-

mis sion pulley.

3. Place new belt in groove of trans-

mis sion pulley and into engine pulley.

BELT MUST BE IN GROOVE ON TOP

OF IDLER PULLEY. NOTE POSITION

OF BELT TO GUIDES.

4. Check belt adjustment as described

be low.

5. Replace belt guard.

6. Reposition wheel and replace clevis

pin and hairpin clip.

GROUND DRIVE BELT AD JUST MENT

For proper belt tension, the extension

spring should have about 5/8 inch stretch

when drive control bar is in “EN GAGED”

po si tion. This tension can be attained as

fol lows:

1. Loosen cable clip screw securing the

drive control cable.

2. Slide cable forward for less tension and

rearward for more tension until about

5/8 inch stretch is obtained while the

drive con trol bar is engaged.

3. Tighten cable clip screw securely.