REV 10855

2-12-08

OPERATION cont.

MAKING BEVEL CUTS (Figs. 16) cont.

WARNING: If the blade comes in contact with the workpiece before it

reaches full speed, it could cause the saw to kickback towards you, possibly

resulting in serious injury.

!

24

MAKING POCKET CUTS ( Fig. 17)

WARNING: ALWAYS adjust bevel setting to zero before making a pocket

cut. Attempting a pocket cut at any other setting can result in a loss of control of

the saw, which can result in serious injury.

!

1. Adjust the bevel setting to zero, set the blade to the correct blade depth setting, then use

the lower blade guard lever to swing the guard up.

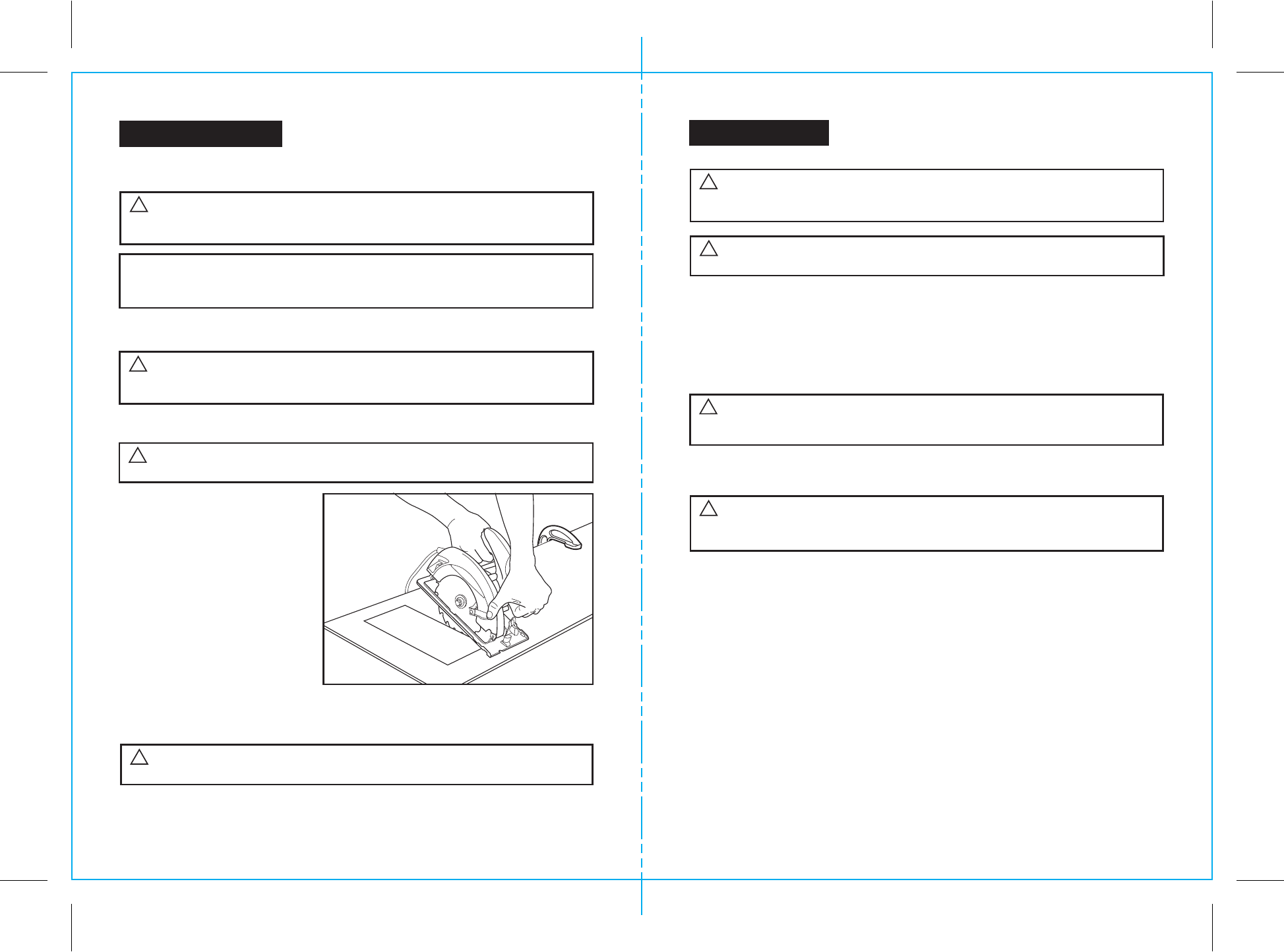

2. While holding the lower blade

guard up by the lever, firmly rest

the front of the saw base flat

against the workpiece with the

rear handle raised so the blade

does not touch the workpiece

(see Fig 17).

3. Squeeze the trigger switch to start

the saw. ALWAYS let the blade

reach full speed, then slowly lower

the blade onto the workpiece until

the base is flat against the

workpiece. AS the blade enters

the material, you MUST release

the lower blade guard lever.

4. After you complete the cut, release the trigger switch and allow the blade to come to a

complete stop. After the blade has stopped, remove it from the workpiece. If the corners

of your pocket cut are not completely cut through, use a hand finishing saw to finish

the corners.

WARNING: ALWAYS raise the lower blade guard with the lever to avoid

serious injury.

!

NOTE: Since the thickness of blades varies, MAKE A TRIAL CUT in scrap material

along the guideline to determine how much, if any, you should offset the blade

from the guideline to allow for the kerf of the blade to get an accurate cut.

Fig. 17

WARNING: NEVER tie the lower blade guard in the raised position. Leaving

the blade exposed could result in serious injury.

!

25

WARNING: To ensure safety and reliability, all repairs - with the exception

of the externally accessible brushes - should be performed by a qualified service

technician at a Sears Service Center.

!

It has been found that electric tools are subject to accelerated wear and possible

premature failure when they are used to work on fiber glass boats and sports cars,

wallboard, spackling compounds or plaster. The chips and grindings from these materials

are highly abrasive to electrical tool parts, such as bearings, brushes, commutators, etc.

Consequently, it is not recommended that this tool be used for extended work on any

fiberglass material, wallboard, spackling compound or plaster. During any use on these

materials, it is extremely important that the tool is cleaned frequently by blowing with an

air jet.

WARNING: For your safety, ALWAYS turn off switch and unplug circular

saw from the power source before performing any maintenance or cleaning.

!

WARNING: Always wear safety goggles or safety glasses with side shields

during power tool operations, or when blowing dust. If operation is dusty, also

wear a dust mask.

!

ROUTINE MAINTENANCE

Periodic maintenance allows for long life and trouble-free operation. A cleaning, lubrication

and maintenance schedule should be maintained. As a common preventive maintenance

practice, follow these recommended steps:

WARNING: DO NOT at any time let brake fluids, gasoline, petroleum-based

products, penetrating oils, etc. come in contact with plastic parts. Chemicals can

damage, weaken or destroy plastic, which may result in serious personal injury.

!

MAINTENANCE

1. When work has been completed, clean the tool to allow smooth functioning of the tool

over time.

2. Use clean damp cloths to wipe the tool.

3.

Check the state of all electrical cables.

4.

Keep the motor air openings free from oil, grease and sawdust or woodchips, and store

tool in a dry place.

5.

Be certain that all moving parts that are exposed are well lubricated, particularly after

lengthy exposure to damp and/or dirty conditions.

LUBRICATION

All of the bearings in this tool are lubricated with a sufficient amount of high-grade lubricant

for the life of the tool under normal operating conditions. Therefore, no further lubrication is

required.