SERVmCE

,i i,

TO ADJUST CARBURETOR

AND A

TO ADJUST:

Q

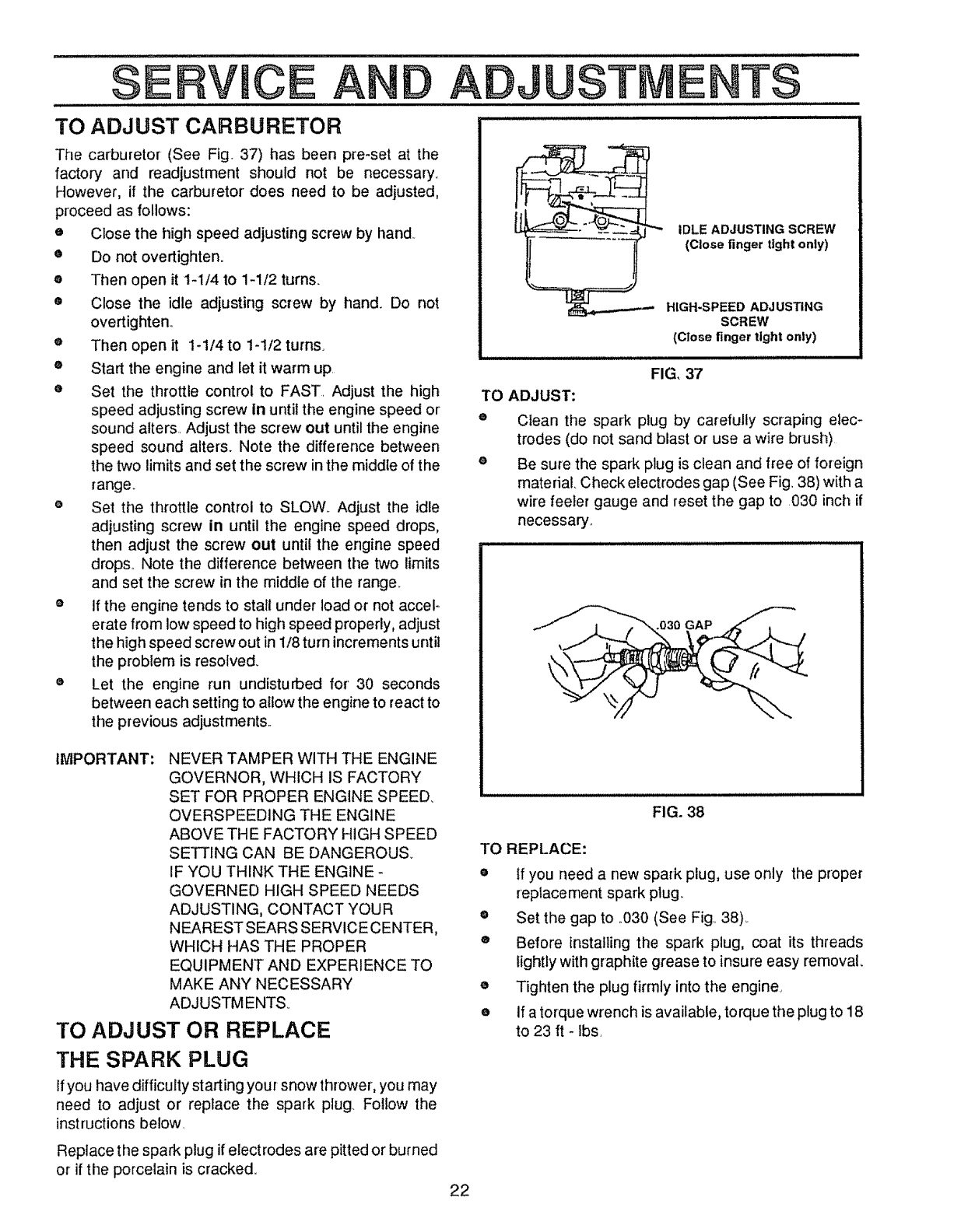

The carburetor (See Fig. 37) has been pre-set at the

factory and readjustment should not be necessary.

However, if the carburetor does need to be adjusted,

proceed as follows:

e Close the high speed adjusting screw by hand

• Do not overtighten.

® Then open it 1-!/4 to 1-1/2 turns.

• Close the idle adjusting screw by hand. Do not

overtighten.

e Then open it 1-114 to 1-112 turns.

® Start the engine and let it warm up.

e Set the throttle control to FAST. Adjust the high

speed adjusting screw in until the engine speed or

sound alter& Adjust the screw out until the engine

speed sound alters. Note the difference between

the two limits and set the screw in the middle of the

range_

e Set the throttle control to SLOW. Adjust the idle

adjusting screw in until the engine speed drops,

then adjust the screw out until the engine speed

drop& Note the difference between the two limits

and set the screw in the middle of the range.

® If the engine tends to stall under load or not acceF

erate from low speed to high speed properly, adjust

the high speed screw out in 1/8 turn increments until

the problem is resolved_

o Let the engine run undisturbed for 30 seconds

between each setting to aitow the engine to react to

the previous adjustments..

TO REPLACE:

JUST E

22

IMPORTANT: NEVER TAMPER WITH THE ENGINE

GOVERNOR, WHICH IS FACTORY

SET FOR PROPER ENGINE SPEED.

OVERSPEED1NG THE ENGINE

ABOVE THE FACTORY HIGH SPEED

SETTING CAN BE DANGEROUS.

IF YOU THINK THE ENGINE -

GOVERNED HIGH SPEED NEEDS

ADJUSTING, CONTACT YOUR

NEAREST SEARS SERVICE CENTER,

WHICH HAS THE PROPER

EQUIPMENT AND EXPERIENCE TO

MAKE ANY NECESSARY

ADJUSTMENTS

TO ADJUST OR REPLACE

THE SPARK PLUG

If you have difficulty starting your snow thrower, you may

need to adjust or replace the spark plug. Fotlow the

instructions below.

Replace the spark plug if electrodes are pitted or burned

or if the porcelain is cracked.

TS

IDLE ADJUSTING SCREW

(Close finger tight only)

HIGH-SPEED ADJUSTING

SCREW

(Close finger tight only)

FIG, 37

Clean the spark plug by carefully scraping elec-

trodes (do not sand blast or use a wire brush)

Be sure the spark plug is clean and free of foreign

material. Check electrodes gap (See Fig. 38) with a

wire feeler gauge and reset the gap to 030 inch if

necessary.

.030 GAP

FIG. 38

• ff you need a new spark plug, use only the proper

replacement spark plug

o Set the gap to .,030 (See Fig 38),.

® Before installing the spark plug, coat its threads

lightly with graphite grease to insure easy removal,

• Tighten the plug firmly into the engine,.

o If a torque wrench is available, torque the plug to 18

to 23 ft - ibs,