9

UK

KICK-BACK PRECAUTIONS

See Figures 4 and 5.

Rotational kick-back (A) occurs when the moving chain contacts

an object at the Kick-back Danger Zone (B) of the guide bar.

The result is a lightning-fast, reverse reaction which kicks the

guide bar up and back towards the operator. This reaction may

cause loss of control which can result in serious injury.

FUEL AND REFUELLING

HANDLING THE FUEL SAFELY

WARNING:

KICK-BACK

occurs when the moving chain contacts an

object at the upper portion of the tip of the guide bar or

when the wood closes in and pinches the saw chain in

the cut. Contact at the upper portion of the tip of the

guide bar can cause the chain to dig into the object

and stop the chain for an instant. The result is a

lightning-fast, reverse reaction which kicks the guide bar

up and back toward the operator. If the saw chain is

pinched along the top of the guide bar, the guide bar can

be driven rapidly back towards the operator. Either of

these reactions may cause you to lose control of the saw,

which could result in serious injury

Do not rely exclusively upon the safety devices built into

your saw. As a chainsaw user, you should take several

steps to keep your cutting jobs free from accident or injury.

WARNING:

Always turn off engine before refuelling. Never add fuel

to a machine with a running or hot engine. Move at least

15 m (50 ft.) from refuelling site before starting the engine.

DO NOT SMOKE! Failure to heed this warning can result

in possible personal injury.

■■

■■

■ Always handle fuel with care: it is highly flammable.

■■

■■

■ Always refuel outdoors and do not inhale fuel vapour.

■■

■■

■ Do not let petrol or oil come in contact with skin.

■■

■■

■ Keep petrol and oil away from the eyes. If petrol or oil comes

in contact with the eyes, wash them immediately with clean

water. If irritation is still present, see a doctor immediately.

■■

■■

■ Clean up spilled fuel immediately.

WARNING:

Check for fuel leaks. If any are found, correct them before

using the saw to prevent fire or burn injury.

}

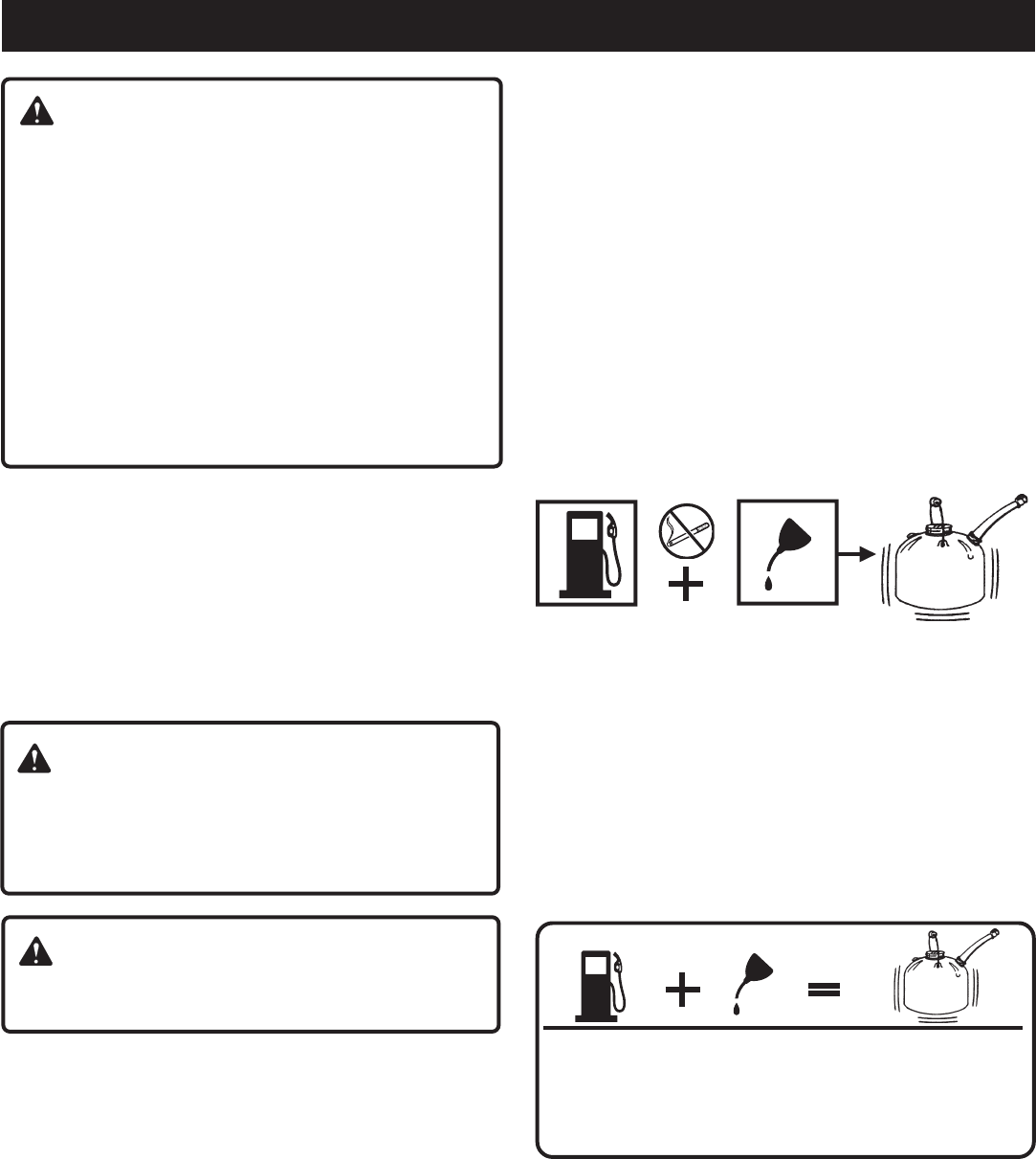

50:1

FILLING THE TANK

See Figure 6.

Refer to “Specific Safety Rules – Refuelling” earlier in this

manual for additional safety information.

1. Clean the surface around fuel cap to prevent contamination.

2. Loosen the fuel cap slowly.

3. Carefully pour the fuel mixture into the tank. Avoid spillage.

4. Prior to replacing the fuel cap, clean and inspect the gasket.

5. Immediately replace the fuel cap and hand tighten. Wipe up

any fuel spillage.

NOTE: It is normal for the engine to emit smoke during and

after the first use.

MIXING THE FUEL

■■

■■

■ This product is powered by a 2-cycle engine and requires

pre-mixing petrol and 2-cycle oil. Pre-mix unleaded petrol

and 2-cycle engine oil in a clean container approved for petrol.

■■

■■

■ This engine is certified to operate on unleaded petrol

intended for motor vehicle use with an octane rating of

87 ([R + M] / 2) or higher.

■■

■■

■ Do not use any type of pre-mixed petrol/oil from fuel service

stations. This includes the pre-mixed petrol/oil intended for

use in mopeds, motorcycles, etc.

■■

■■

■ Use a high quality 2-cycle self-mixing oil for air-cooled

engines. Do not use motor vehicle oil or 2-cycle outboard oil.

■■

■■

■ Mix 2% oil into the petrol. This is a 50:1 ratio.

■■

■■

■ Mix the fuel thoroughly each time before refuelling.

■■

■■

■ Mix in small quantities. Do not mix quantities larger than

usable in a 30-day period. A 2-cycle oil containing a fuel

stabiliser is recommended.

1 Litre + 20 ml =

2 Litres + 40 ml =

3 Litres + 60 ml =

4 Litres + 80 ml =

5 Litres + 100 ml =

CHAIN OIL SYSTEM

See Figure 7.

Use RYOBI Bar and Chain Oil. It is designed for chains

and chain oilers, and is formulated to perform over a wide

temperature range with no dilution required. Chainsaw should

use approximately one tank of oil per tank of fuel.

OPERATION