-

19

-

5-4 OIL SENSOR

5-4-1 DESCRIPTION

* The oil sensor mainly functions to detect posi-

tion of the surface of engine oil in the crankcase

of engines for general use and to stop the en-

gine automatically when the oil level goes down

below the lower limit specified. This prevents sei-

zure of engine from occurring due to insufficient

amount of oil in the crankcase.

* Since the sensor has been designed to consume

a part of power supplied to the igniter to ener-

gize its electronics circuit, any other external

power supply is not necessary so that it can be

mounted at the oil filler port.

Introduction of newly developed sensing principle features super durability and no change with the

passage of time as it does not use any moving part.

Merits due to introduction of electrical conductivity detection are as follows ;

1 It has resistance to mechanical shocks and property of no change with the passage of time as

sensing element consists simply of electrodes having no moving parts.

2 At the same time, it is capable of detecting the oil level stably as it is not influenced by engine

vibrations.

3 No error occurs due to foam and flow of the oil.

4 Influence against the ignition system or the electronics units can be neglected because an electric

current supplied to the sensor can be decreased.

5-4-2 PRINCIPLE OF SENSING OIL LEVEL

There is a great difference between electric resistance of air and that of oil. Since the resistance of air is

far higher than that of oil, more electric current passes through the oil than through the air, although

absolute value of the current is very small. The sensor detects this current difference and make use of it.

The sensor judges the oil quantity, by comparing a current flowing across a pair of electrodes (inner and

outer) with the reference, in such a way that if a current flows between the electrodes more than the

reference, sufficient oil is in the crankcase, on the other hand, if a current flows less than the reference,

oil is not sufficient. Since an electric current is flown to detect oil quantity, this is called the “electrical

conductivity detection” type of sensor. The oil level to be detected is determined by the length of elec-

trodes and their mounting positions with the engine.

5-4-3 HOW IT OPERATES

[Power supply]

The sensor makes use of a part of primary power source for ignition of the engine (igniter) to drive the

sensor circuit. Power to the sensor can usually be derived from the “stop button” by branching wires out.

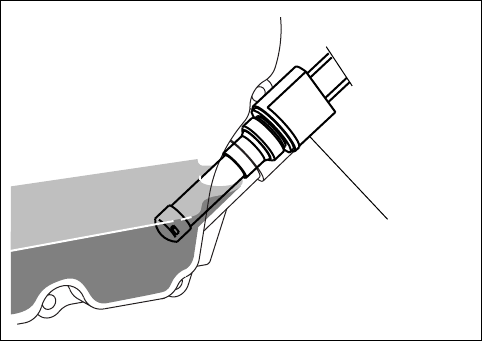

Fig. 5-15

OIL SENSOR