US-23

EXZ2460S-PH

U

S

9. Maintenance

■ MAINTENANCE CHART

Maintenance, replacement, or repair of the emission control device and systems may be performed by any

non-road engine repair establishment or individual.

every every every

25 50 100

system/compornent procedure before hours hours hours note

use after after after

fuel leaks, fuel spillage wipe out ✔

fuel tank, air filter, fuel filter inspect/clean ✔✔ replace, if necessary

see ■ADJUSTING replace carburetor

idle adjusting screw ✔

IDLING SPEED (p.16) if necessary

clean and readjust GAP: .026in (0.65mm)

spark plug ✔

plug gap replace, if necessary

cylinder fins, intake air cooling vent clean ✔

muffler, spark arrester, cylinder exhaust port

clean ✔

throttle lever, ignition switch check operation ✔

replace if BC-EX3, LRT-EX3,

cutting parts ✔

something's wrong HE-EX2

debris guard make sure to attach ✔ BC-EX3, HE-EX2

gear case grease ✔

screws/nuts/bolts tighten/replace ✔✔not adjusting screws

oiling port clean ✔ PS-EX only

guide bar clean ✔ PS-EX only

sprocket inspect/replace ✔ PS-EX only

saw chain inspect/sharp ✔ PS-EX only

replace if

sweeper unit ✔ RMS-EX only

something's wrong

ENGINE

SHAFT

• Make sure that the engine has

stopped and is cool before

performing any service to the

machine. Contact with moving

cutting head or hot muffler may

result in a personal injury.

■ AIR FILTER

• The air filter, if clogged, will reduce the

engine performance. Check and clean

the filter element. If the element is

broken or clogged, replace with a new

one. (MA1)

(1) air filter

■ FUEL FILTER

• When the engine runs short of fuel

supply, check the fuel cap and the fuel

filter for blockage. (MA2)

(1) fuel filter

WARNING

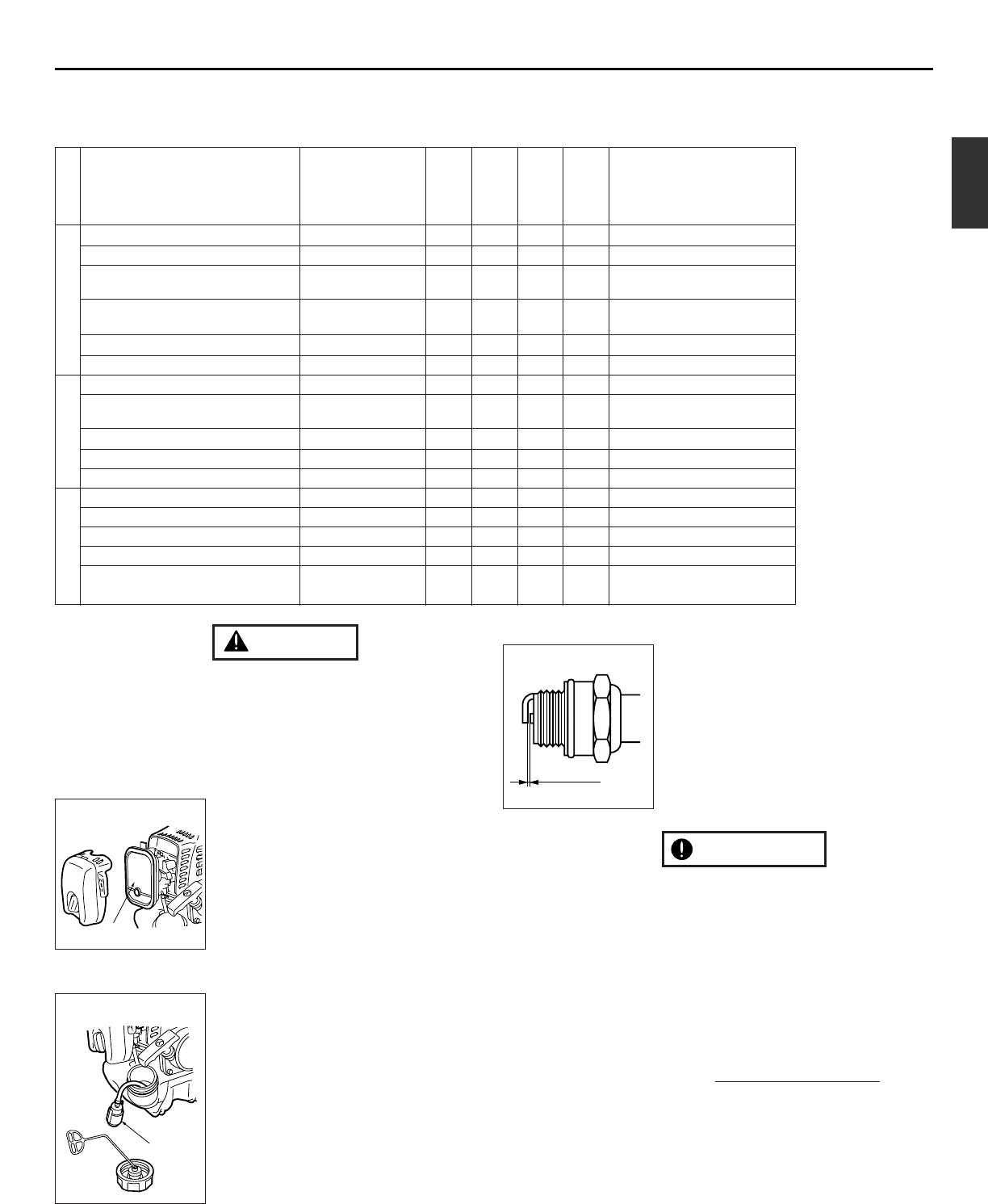

■ SPARK PLUG

• Starting failure and mis-firing are often

caused by a fouled spark plug. Clean

the spark plug and check that the plug

gap is in the correct range. For a

replacement plug, use the correct type

specified by RedMax. (MA3)

• REPLACEMENT PLUG IS A NGK

CMR7H.

• Note that using any spark plug other

than those designated may result in the

engine failing to operate properly or in

the engine becoming overheated and

damaged.

• To install the spark plug, first turn the

plug until it is finger tight, then tighten it

a quarter turn more with a socket

wrench.

TIGHTENING TORQUE:

87~104 in-lbs

(9.8~11.8 N.m.)

IMPORTANT

(1)

MA1

(1)

MA2

.026 in

0.65 mm

MA3

CUTTING UNIT