30 200-2341

Engine spark plugs are an important part of the

engine ignition system. Worn or incorrectly adjusted

spark plugs can negatively affect engine starting and

operation. Therefore, it is important to inspect and regap,

or replace the engine spark plugs as indicated in the

service interval table. The listed steps are recommended

to access and service the engine spark plugs.

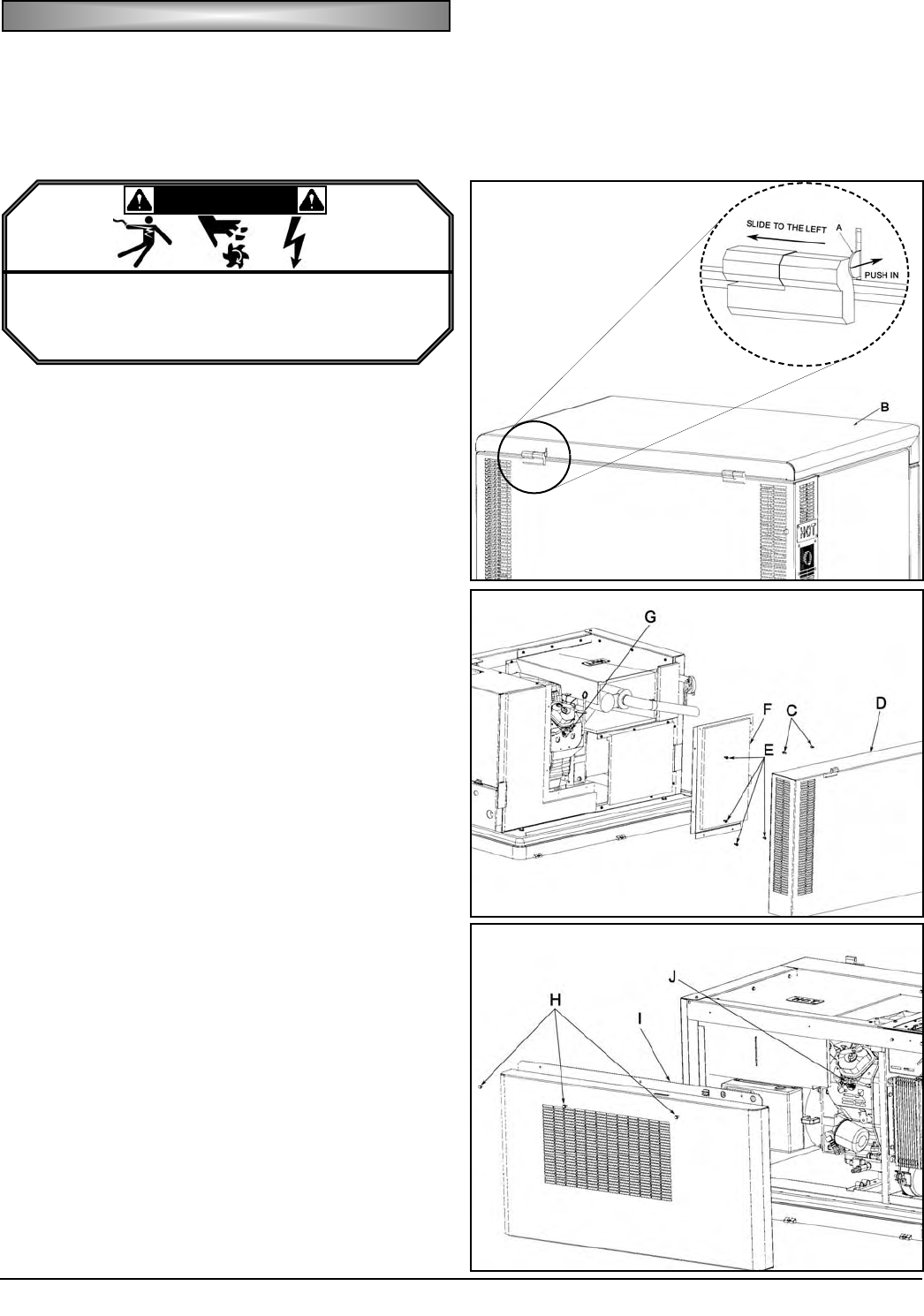

1. To gain access to the spark plug on the rear side of

the engine, some disassembly of the generator

cabinet is required. Begin the disassembly by

carefully removing the lid from the enclosure. First

remove the ground strap by removing the screw

holding it to the lid. Push in the hinge retaining stop

(A), then slide the lid (B) to the left to free it from the

rest of the enclosure as shown in Fig G. Set the lid

aside on a soft surface to avoid scratching the paint.

2. Open the battery access panel by removing the 3

screws and rotating the panel outward (see Fig. E on

page 28).

3. Remove the 2 screws (C) fastening the exhaust

chamber to the rear engine firewall (see Fig H).

Slide the exhaust chamber panel (D) upward to free

it from the enclosure and carefully set it aside.

4. Locate and remove the screws (E) retaining the

spark plug access cover (F). Remove the cover to

gain access to the rear spark plug (G) as shown in

Fig H.

5. Remove the enclosure inlet fasteners (H) and front

panel (I) as indicated in Fig I to access the front

engine spark plug (J).

6. Pull the spark plug boots loose, then clean any dirt

from the area around the spark plugs. Remove the

spark plugs with a 13/16" spark plug wrench.

7. Inspect the spark plugs for fouling or abnormal wear

like excessively worn electrodes or cracked or

chipped insulator material. If abnormal wear is

indicated, replace the spark plugs. Fouled plugs

indicate the need for engine service by a qualified

engine service technician.

New spark plugs or plugs that do not display any

abnormal characteristics should be checked for

proper gap using a suitable spark plug gauge.

Adjust the gap to 0.012 - 0.016 inches (0.30 - 0.40

mm) by carefully bending the grounding electrode.

8. Reinstall the spark plugs by hand until they begin to

seat to avoid cross-threading. After the plugs begin

to seat, tighten used plugs an additional ¼ turn or

13/16" spark plug wrench to avoid damage to the

spark plugs. If a torque wrench is available, tighten

all plugs to 13 in-lbs (18 N-m).

9. Finish the procedure by reassembling the enclosure

front panel (I), spark plug access cover (F), exhaust

chamber (D) and enclosure lid (B).

SS

SS

PP

PP

AA

AA

RR

RR

KK

KK

PP

PP

LL

LL

UU

UU

GG

GG

CC

CC

HH

HH

EE

EE

CC

CC

KK

KK

Fig. G

Fig. H

Fig. I

WWAARRNNIINNGG

• Before performing any maintenance, make sure

the Mode switch is in the OFF position, the

circuit breaker is in the OFF position and the

positive (red) battery cable is disconnected.