7

3. While securely holding the upper shaft,

pull the attachment straight out of the

coupler.

INSTALLING OPTIONAL ATTACH-

MENTS

1. Remove the shaft cap from the attach-

ment (if present) and discard.

2. Position locking/release buttonof attach-

ment into guide recess of upper shaft

coupler.

Coupler

Primary Hole

Upper

Shaft

Locking/

Release

Button

Attachment

Guide Recess

3. Pushtheattachmentintothecoupleruntil

the locking/release button snaps into the

primary hole.

4. Beforeusingthe unit,tightentheknobse-

curely by turning clockwise.

INSTALLING ATTACHMENT

HANGER

An attachment hangeris provided forstorage

whenattachmentis notin use.To install hang-

er on attachment:

1. Remove the shaft cap from the attach-

ment (if present) and discard.

2. Press and hold the locking/release but-

ton.

3. Push hanger onto the attachment until

the locking/release button snaps into the

hole.

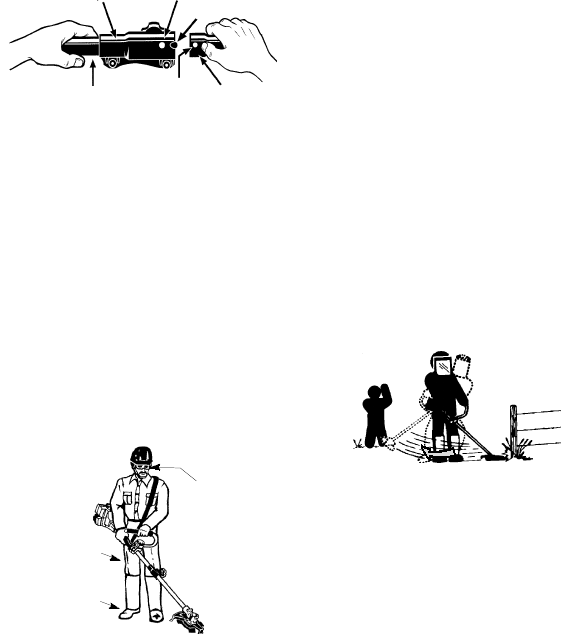

OPERATING POSITION

Boots

Heavy ,

Long Pants

Eye Protection

ALWA YS WEAR:

Cut from your left to your right.

NOTE:

This brushcutter attachment is not

designed for use with electric powerheads.

When operating unit with brushcutter attach-

ment, clip shoulder strap onto up per shoulder

strap clamp, stan d as shown and check for the

f ollo wing :

S

Wear eye protection and heavy clothing.

S

Keeparms extendedwithrighthandholding

the trigger handle of powerhead.

S

Keep left arm extended with left hand hold-

ing the handlebar.

S

Keep unit below waist level.

S

Shoulder strap pad should be centered on

your left shoulderand dangersign centered

on your back.

S

Maintain full weight of tool on left shoulder.

S

Without bending over , ke ep the blade near

and parallel to the ground andnot crowdedin-

to material being cut.

OPERATING INSTRUCTIONSFOR

BRUSHCUTTER ATTACHMENT

S

Blade Thrust

is a reaction t hat only oc curs

when u sing a bladed unit. This reaction can

cause se rious injury such as amputation.

Carefully study this section. It is importantthat

you understand what causes bla de thrust,

how you can reduce the chance of its occur-

ring, and how you canre main in control of u nit

if blade thrust occurs.

S

WHAT CAUS ES BLADE THRUS T

--

Blad e

Thrust

can occur when spinn ing blade con-

tacts a nobjectthatitdoes n otcut. This contact

causes blade to stop for an instant and then

suddenly move or “th rust” away from object

that was hit. The “thrusting” r eaction can be

violent enough to ca use operator to b e pro-

pelled in any direction and lose control of unit.

Theuncontrolled unit cancause serious injury

if blade contacts operator or others.

S

WHEN BLADE THRUST OCCURS --

Blade Thrust

can occur without warning if

the blade snags, stalls, or binds. This is

more likely to occur in areaswhereit is diffi-

cult to see the material being cut. By using

the unit properly, the occurrence of blade

thrust will be reduced and the operator will

be less likely to lose control.

S

Cutonlygrass, weeds, an d wood y bru sh upto

1/2 inch (1 cm) in diameter with weed blade.

Do not let blade contact material it cannot cut

su chas stum ps, r ocks , fence s , m et al, et c ., o r

clusters of hard, woody brush with a diameter

greater than 1/2 inch (1 cm).

S

Useasharpblade.Adullbladeis morelikely

to snag and thrust.

S

Cut on ly at full throttle. The b lade will have

maximum cu tting power and is less like ly to

bind or stall.

S

“Feed” the blade deliberately and not too

rapidly.The bladecan thrustaway if it is fed

too rapidly.

S

Cut only from your left to your right. Cutting on

right side of the shield will th row debr is a wa y

from the operator .

S

Use the shoulder strap and keepa firm grip

on the unit with both hands. A properly ad-

justedshoulderstrap willsupport theweight

of the unit, freeing your arms and hands to

control and guide the cutting motion.

S

Keep feet comfortably spread a part and

braced for a possible sudden, rapid th rust of

unit. Do not overrea ch. Keep firm foo ting and

balance.