14

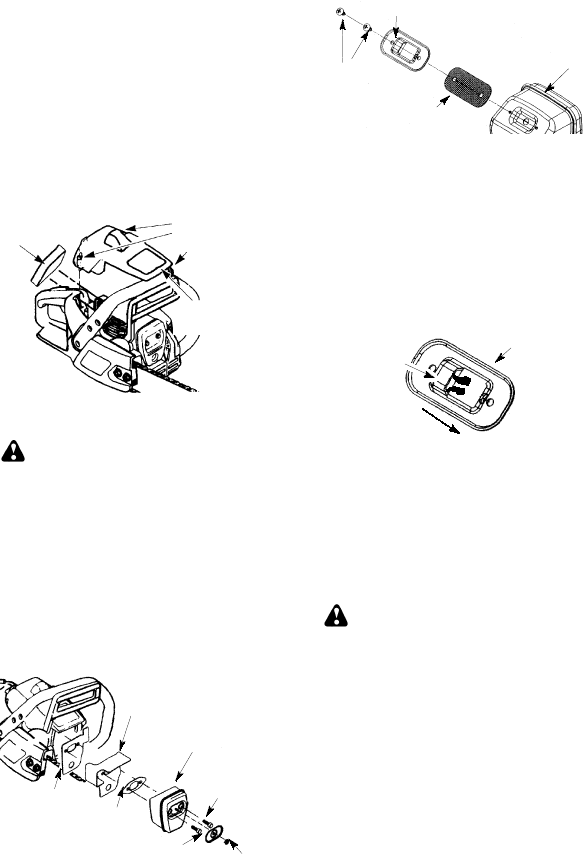

AIR FILTER

CAUTION

:

Do not clean filter in gasoline

or other flammable solvent to avoid creating

a fire hazard or producing harmful evapora-

tive emissions.

Cleaning the air filter:

A dirty air filter decreases engine perform-

ance and increases fuel consumption and

harmful emissions. Alwaysclean afterevery

5 hours of operation.

1. Loosen 3 screws on cylinder cover.

2. Remove cylinder cover.

3. Remove air filter.

4. Clean theairfilterusinghotsoapywater.

Rinse with clean cool water. Air dry

completely before reinstalling.

5. Lightly oil air filter beforeinstalling to im-

prove the efficiency of air filter. Use

2--cycle engine oil ormotoroil (SAE 30).

Squeeze excess oil from filter.

6. Reinstall air filter.

7. Reinstall cylinder cover and 3 screws.

TIghten securely.

Air Filter

Cylinder Cover

Screws

Cylinder

Cover

INSPECT MUFFLER AND SPARK

ARRESTINGSCREEN

W ARNING:

The muffler on this

product contains chemicals known to the

State of California to cause cancer.

As theunit is used, carbon deposits build up

on the muf fler and spark arresting screen,

andmust be removedtoavoidcreatinga fire

hazard or affecting engine performance.

Replace thespark arrestingscreen ifbreaks

occur.

CLEANING THE SPARK ARREST-

ING SCREEN

Cleaning is required every 25 hours of op-

eration or annually, whichever comes first.

Muffler

Gasket

Muffler

Bolts

Muffler

Locknut

Outlet

Guide

Bolt Cover

Backplate

1. Loosenandremovethelocknutfrom the

bolt cover .

2. Remove the bolt cover .

3. Loosen and remove the 2 muffler bolts.

Remove themuffler,muffler gasket,out-

let guide and backplate. Notice the ori-

entationofthesepartsforreassembling.

4. Locate t he 2 outlet cover screws on the

muffler. Loosen and remove both

screws.

5. Remove the outlet cover.

BACK VIEW OF

MUFFLER

Muffler

Spark Arresting

Screen

Outlet Cover

Screws

6. Remove spark arresting screen.

7. Clean the spark arresting screen with a

wire b rush. Re place screen if any wires

a r eb rokenor screen i sblo cked af ter c lea-

ning.

8. Reinstall spark arresting screen.

9. Reinstall outletcover and2 screws. En-

sure outlet cover and

both

screws are

reinstalledcorrectly (seeillustrations)to

prevent damage to the saw. The ex-

haust outlet must face the chain brake

(bar side) of the saw.

Exhaust Outlet must face chain

brake (bar side) of chain saw

Outlet Cover

Exhaust

Outlet

10. Inspect themuffler gasket andreplaceif

damaged.

11. Reinstall backplate,outlet guide,muffler

gasket, and muffler using muffler bolts.

Tighten until secure.

12. Reinstall boltcover andl ocknut. Tighten

securely.

CARBURETOR ADJUSTMENT

WARNING:

The chain will be mov-

ing during mostof this procedure.Wearyour

protective equipment and observe all safety

precautions.Thechain mustnotmoveatidle

speed.

The carburetor has been carefully set at the

factory. Adjustments may be necessary if

you notice any of the following conditions:

S

Chain moves at idle. See IDLE SPEED--T

adjusting procedure.

S

Saw will not idle. SeeIDLESPEED--T ad-

justing procedure.

Idle Speed--T

Allow engine to idle. If the chain moves, idle

is toofast. Iftheenginestalls, idle istoos low.

Adjust speed until engine runs without chain

movement (idle too fast) or stalling (idle too

slow). Theidle speedscrew is located inthe

area above the primer bulb and is labeled T.