12

CHECK FOR LOOSE FASTENERS

AND PARTS

S Bar Clamp Nuts

S Chain

S Bar Adjusting Screw

CHECK CHAIN TE NSION

WARNING: Wear protective

gloves when handling chain. The chain

is sharp and ca n cut you even when it is

not moving.

Chain ten sion is very import ant. C hain

stretches during use. This i s especially

trueduringthe fi rstfew timesyou useyour

saw . Always check chain tension each

ti me you use your saw .

1. Unpl ug unit from the p ower source.

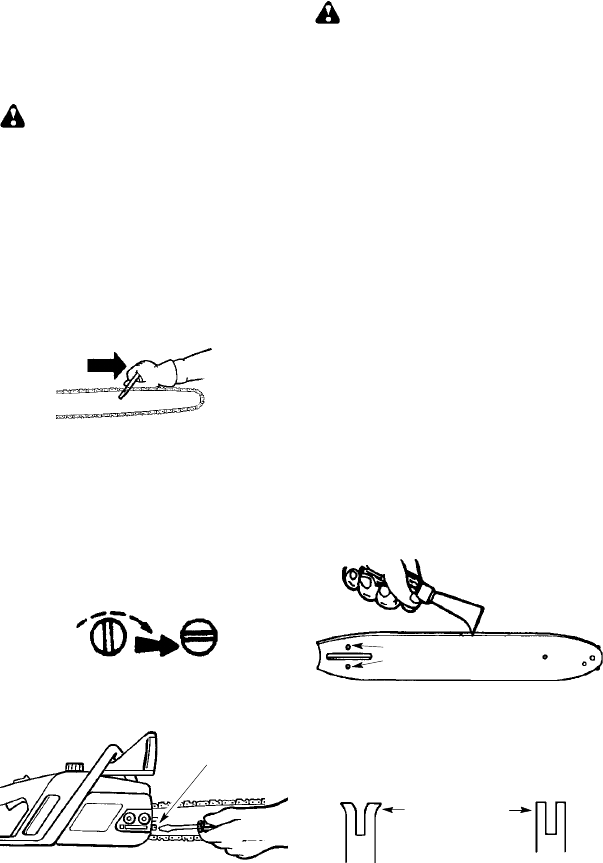

2. Use a screwdr iver to move chain

around guide bar to ensure k inks do

not exist. The chain should rotate

freely .

NOTE: It is recommended that the saw

be turned upside down for cha in

tensioning.

3. Loos en bar clamp nuts until they are

finger tight against the bar clamp.

4. Turn the adjus t ing screw clockwise

until the chain solidl y contacts bottom

of guide bar r ai l . Then, tur n adjusting

screw an ad di t i onal 1/4 tur n. This is

correct chai n tension setting.

Adjusting Screw -- 1/4 Turn

NOTE: To t ighten the chain, turn th e ad-

just ing screw clockwise; t o loosen the

chain , turn the adjusti ng screw counter-

clockwi se .

Adjusting Screw

5. Check t he tension by lifting the chain

fr om the guide bar. Remove s ome of

the stiffness in the chain by pulling

downand lettinggo ofthe chainsever-

al times.

6. Conti nue tur ni ng t he adjusti ng scr ew

until t he tension is correct ( see step 4).

7. T i ght en bar clamp nut s wit h a wrench.

8. Recheck chain tension.

WARNING: If the saw is operated

with a loose chain, the chain could jump

off the guide bar and resultin serious in-

jury.

CHECK CHAIN SHARPNESS

A sharp chain makes woodc hips. A dull

chain makes a sawdust powder and

cuts slowly. See

CHAIN SHARPENING in

the

SERVICE AND ADJUSTMENTS

section.

CHECK GUIDE BAR

Conditi ons which requir e guide bar main-

tenance:

S Saw cuts to one side or at an angle.

S Saw has to be forced t hr ough the cut.

S Inadequate supply ofoilto the barand

chain.

Check the condit i on of the guide bar each

ti me the chain is sharpened. A worn gui de

bar will damage the chain and make cut-

ti ng diff i cul t .

Aft er each use, with uni t disconnected

fr ompower source,clean allsawdustfrom

the guid e bar and sprocket hole.

To maintain guide bar:

S Disconnect the chain s aw from the

power source.

S Loosen and remove bar clamp nut s.

Remove bar and chain from saw.

S Clean the oil holes and bar groove af-

ter each 5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Oil Holes

S Burring of guide bar rails is a normal

process of rail wear. Remove these

burrs with a flat file.

S When rail top is uneven, use a flat file

to restore square edges and sides.

Correct GrooveWorn Groove

File Rail Edges

and Sides

Square

Replace the guide bar when the gr oove is

worn, the guide bar is bentor cr ack--ed, or

when excess heating orburring ofthe r ai ls

occur s. I f repl acem en t i s necessar y, use

only t he guidebarspecified f oryoursawin

the repair part s listor on t h e decal located

on t he chain saw.