6

The following guide barand chain combina-

tions meet kickback requirements of CSA

Z62.1, Z62.3, &ANSI B175.1when usedon

saws listed in this manual. Use of bar and

chaincombinationsotherthanthoselistedis

not recommended and may not meet the

CKA requirements per standard.

Computed kickback angle (CKA) Table

BAR

P/N Length CHAIN P/N

MODEL

545049001 20″ 952051310 31_

CKA without chain brake

PP4620AVHD

NOTE: Ifthissawistobeusedforcommer-

cial logging, a chain brake is required and

shall not be removed or otherwise disabled

to comply with Federal OSHA Regulations

for Commercial Logging.

SAFETY NOTICE: Exposure to vibrations

through prolonged use of gasoline powered

hand tools could cause blood vessel or nerve

damage in the fingers, hands, and joints of

people prone to circulation disorders or

abnormal swellings. Prolonged use i n cold

weather has been linked to blo od vessel

damage in otherwise healthy people. If

symptoms occur such as numbn ess, pain,

loss ofstrength,changeinskincolorortexture,

or loss offeeling i nthe fingers, hand s, orjoints,

discontinue the use of this tool and seek

medical attention. An anti-vibration system

does not guarantee the avoidance of these

problems. Users who operate power tools on

a continual and regular basis must monitor

closely t heir physical condition a nd the

condition of this tool.

SPECIALNOTICE:Yoursawisequipped

with atemperaturelimiting muf flerandspark

arresting screen which meets the

requirements of California Codes 4442 and

4443. All U.S. forest land and the states of

California, Idaho, Maine, Minnesota, New

Jersey,Oregon, andWashington require b y

law that m any internal combustion engines

tobeequippedwithasparkarrestingscreen.

Ifyouoperateachainsawinastate orlocale

wheresuchregulations exist,youarelegally

responsible for maintaining the operating

condition of these parts. Failure to do so is

aviolationof t helaw. Referto theSERVICE

section for maintenance of the spark

arresting screen.

FailuretofollowallSafetyRulesandPrecau-

tionscanresult inserious injury. Ifsituations

occur which are not covered in this manual,

use care and good judgement. If you need

assistance, contact your authorized service

dealer or call 1-800--554--6723.

STANDARDS: This saw is listed byUnder-

writer’ s Laboratories, Inc., in accordance with:

ANSI B175.1--2000 American National

Standards fo r Gasoline--Powered Chain

Saws -- Safety Requirements

CSA Z62.1--1995 Chain Saws -- Occupa-

tional Health and Safety

CSA Z62.3--1996 Chain Saw Kickback Oc-

cupational Health and Safety

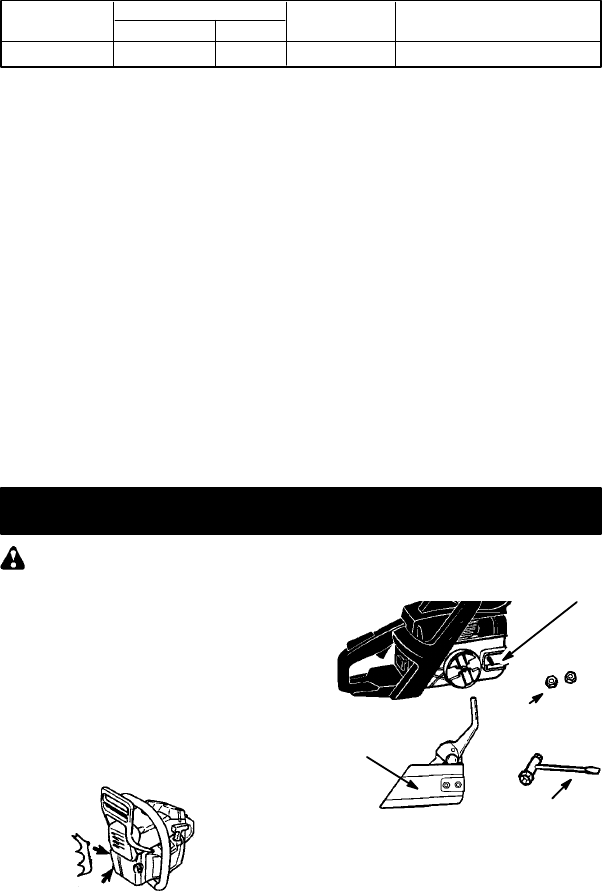

ASSEMBLY

WARNING: If re ceived assem bled,

repeat all steps to ensure your saw isproperly

assembled and all fasteners are secure. Al-

ways wear protective gloves (not included)

when handling the chain. The chain is sharp

and can cut you even when it is not moving!

ATTACHING THE BUMPER

SPIKE

The bumper spike may be used as a pivot

when making a cut.

1. Loosenandremovethechainbrakenuts

and the chain brake from the saw.

2. Attach the bumper spike with the two

screws as illustrated.

ATTACHINGTHEBAR&CHAIN(Ifnot

already attached)

1. Loosenandremovethechainbrakenuts

and the chain brake from the saw.

2. Remove the plastic shipping spacer (if

present).

Chain Brake

Chain Brake

Nuts

Bar Tool

Location of shipping spacer

3. An adjusting pin and screw is used to ad-

just the tension of the chain. It is very im-

portant when assembling the bar, that the

pin located on the adjusting screw aligns

intoaholeinthebar.Turni ngthe s crew w ill

move the adjustment pin up and down the

screw. Locate this adjustment before you

begin mounting the bar onto the saw . See

illustration below.