13

S

Check bar and chain oil before use

and every 15 minutes while operating

the saw. See

GUIDE BAR AND CHAIN

OIL

under the

OPERATION

section.

S

Lubricate bar sprocket hole after each

use.

INSPECT AND CLEAN UNIT AND

LABELS

S

After each use, inspect complete unit

for loose or damaged parts. Clean the

unit andlabels using a damp cloth with

a mild detergent.

S

Wipe off the unit and labels with a

clean dry cloth.

SERVICE AND ADJUSTMENTS

CHAIN SHARPENING

Chain sharpening requires special tools.

You can purchase sharpening tools at an

authorized service dealer or go to a pro-

fessional chain sharpener .

WARNING:

A void accidental start-

ing. Always unplug saw from power

source be fore insta lling a bar and/or

chain.

CHAIN REPLACEMENT

WARNING:

Wear protective

gloves when handling chain. The chain

is sharp and can cut you even when it is

not moving.

It is normal for anewchain to stretchdur -

ing the first 30 minutes of operation. You

should recheck your chain tension fre-

quently and adjust the chain tension as

required. See

CHECK CHAIN TENSION

section.

Replace the old chain when it becomes

worn or damaged. Use only the Low

Kickback replacement chain s pecified

in the list of available replacement parts.

The chain must complywith kickbackre-

quirements of ANSI B175.1 whentested

with this saw. See your authorized ser -

vice dealer to replace and sharpen indi-

vidual cutters on your chain.

TO REPLACE CHAIN:

D

Disconnect the chain saw from the

power source.

Bar Nuts

Adjusting Screw

Bar

Clamp

S

Removebar mounting nuts, bar clamp

plate, and old chain.

S

Turn the adjusting screw counter-

clockwise tomove the adjusting pin al-

most as far as it will go to the rear. Do

not remove the adjusting screw from

the unit.

S

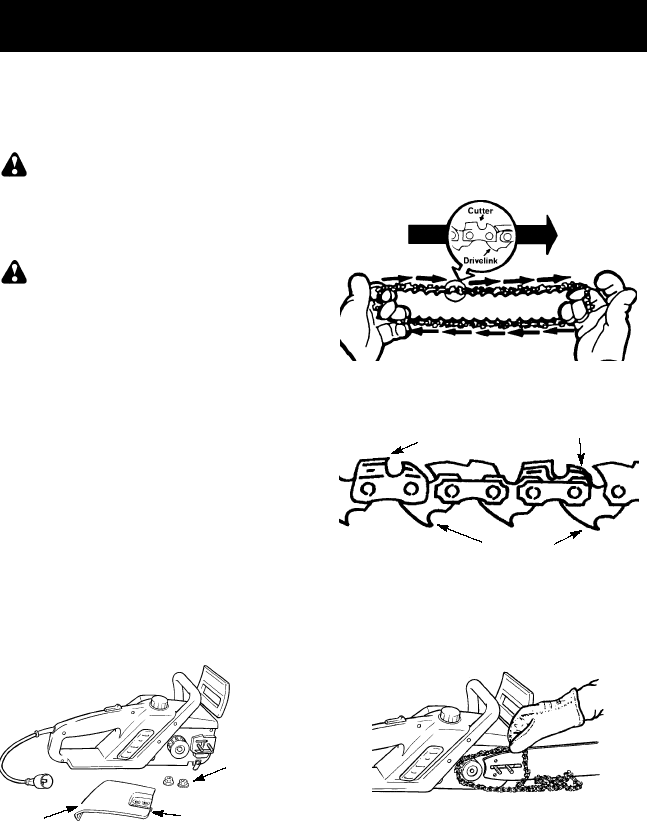

Hold chain with cutters facing as

shown.

CUTTERS MUST FACE IN

DIRECTION OF ROTATION

Tip of

Bar

Cutters

Depth Gauge

Drive Links

S

Place chain around the sprocket and

fit the drive links into the guide bar

groove and then around guide bar

nose.

S

Hold the guide bar against the saw

frame and install the bar clamp.

Be sure adjusting pin is in the adjust-

ingpinholeinthebar.