14

MAINTENANCE SCHEDULE

Lubricate bar

sprocket hole After each use.......

Check:

Fuel mixture level Before each use....

Bar lubrication Before each use.......

Chain tension Before each use.......

Chain sharpness Before each use....

For damaged parts Before each use..

For loose caps Before each use......

For loose fasteners Before each use...

For loose parts Before each use......

Inspect and Clean:

Bar Before each use................

Complete saw After each use.......

Air filter Every 5 hours*.............

Chain brake Every 5 hours*........

Spark arrestor screen

and muffler Every 25 hours*.........

Replace spark plug

Yearly.

Replace fuel filter

Yearly...

* Hours of Operation

AIR FILTER

CAUTION:

Do not clean filter in gasoline

or other flammable solvent to avoid creating

a fire hazard or producing harmful evapora-

tive emissions.

Cleaning the air filter:

A dirty air filter decreases engi ne perform-

ance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

S

Clean the cover and t he area around it to

keep dirt and sawdust from falling into the

carburetor chamber when the cover is re-

moved.

S

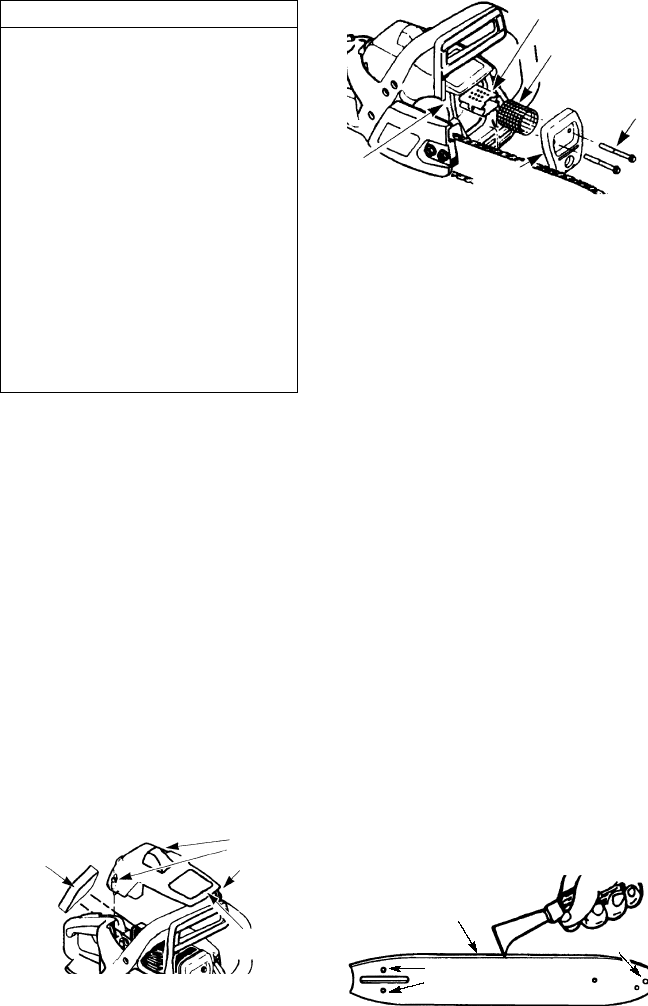

Remove the parts as illustrated below.

S

Wash the filter in soap and water. Rinse in

clean coolwater. Airdry completely before

reinstalling.

S

Lightly oil air filter before installing to im-

prove the efficiency of the air filter. Use

2 --cycle engine oil or motor oil (SAE 30).

Squeeze excess oil from filter.

S

Reinstall parts.

Air Filter

Cylinder

Cover

Screws

Cylinder

Cover

INSPECT MUFFLER AND SPARK

ARRESTING SCREEN

As the unit is used, carbon deposits build up

on the muffler and spark arresting screen,

and must be removed to avoidcreating a fire

hazard or affecting engine performance.

Replace the spark arresting screen if breaks

occur.

Muffler Diffuser

Muffler

Cover

Screws

Muffler

Cover

Muffler

Body

Spark

Arresting

Screen

Cleaning i s required e ver y 25 hours of opera-

tion or annually , whichever comes first.

S

Loosen and remove the 2 muffler cover

screws.

S

Remove the m uf fler cover (cover snaps off

muffler body).

S

Remove muffler diffuser and spark arresting

screen assembly. Notice the or ientation of

these par ts f or reassembling.

S

Clean t he spark arrestor screen with a wire

brush. Replace screen i f breaks are found.

S

Replace any br oken or cracked muf fler

parts.

S

Reinstall diffuser and spar k ar r estor scr een

assembly with round hol es facing up.

S

Reinstall muffler cover and 2 screws. Tight-

en securely.

CARBURETOR ADJ USTMENTS

Your car bur etor i s equipped with limiter caps.

Carbur etor adjustment is a complicated task.

We recommend that you take your unit to an

authorizedservice dealer. Damagewill occurif

you tur n the needl es beyond the limiter stops.

BAR MAINTENANCE

If your saw c uts t o one side, has to be forc ed

through t he cut, or been run with an i mpr oper

amount of bar lubrication i t may be necessary

to service y our bar. A worn bar will damage

your chai n and make cut ting di f ficult.

After each use, ensur e ON/STOP switch is in

theSTOPposition, thenclean allsawdust from

the guide bar and sprocket hole.

To maintain guide bar:

S

Move ON/STOP switch to the ST OP posi-

tion.

S

Loosen and r em ove chain brake nuts and

chain brake. Remove bar and chain from

saw.

S

Cleantheoil holes andbargroove a ftereach

5 hours of operation.

Remove Sawdust From

Guide Bar Groove

Sprocket Hole

Oil H oles

S

Add lubricant to sprocket hole after each

use.

S

Burringof guidebar r ailsis a nor malprocess

of rail wear. Remove these bur r s with a flat

file.

S

When rail top i s uneven, use a f lat file to re-

store s quar e edges and sides.