8

Cut using the 2

o’clock to 4 o’clock

position of the

blade

2 o’clock

4 o’clock

RECOMMENDED CUTTING POSITION

WARNING: The operator or others

mustnot tryto clearawaycutmaterial withthe

engine running or the blade turning to avoid

serious injury. Stop engine and blade before

removing materials wrapped around blade or

shaft.

MAINTENANCE

WARNING: Always stop unit and dis-

connect spark plug wire before performing

maintenance.

CHECK FOR DAMA GED OR

WORN PARTS

Contact an authorized service dealer for re-

placement of damaged or worn parts.

S BladeShield -- Discontinueuseofbrushcut-

ter attachment if shield is damaged.

CHECK FOR LOOSE FAST E NER S

AND PARTS

S Blade nut

S Fasteners

INSPECT AND CLEAN UNIT

AND DECALS

S After each use, inspect complete unit for

loose or damagedparts. Clean theunit and

decals using adamp cloth witha milddeter-

gent.

S Wipe off unit with a clean dry cloth.

BLADE MAINTENANCE

WARNING: The bladewill continue to

spin after the engine stops orafter thethrottle

trigger has been released. To avoid serious

injury, m ake sure the blade has stopped

coastinganddisconnectthespark plugbefore

performing work on the blade.

WARNING: Always replace a blade

thatis bent,warped,cracked,broken, ordam-

aged in any other way. Never attempt to

straighten and reuse a damaged blade. Use

only specified replacement blade. Wear pro-

tective gloves when handling or performing

maintenance on theblade tohelp avoid injury.

S Check blade for flatness periodically. Lay

the bladeon a flatsurface to inspect for flat-

ness. Throw away a blade that is not flat.

SERVICE AND ADJUSTMENTS

BLADE REPLACEMENT

WARNING: The blade will continue to

spin after the engine stops orafter thethrottle

trigger has been released. To avoid serious

injury, make sure the blade has stopped

coastinganddisconnectthespark plugbefore

performing work on the blade.

WARNING: W ear protective gloves

when handling or performing maintenance on

the blade to avoid injury . The blade is sharp and

can cut you even when it is not moving.

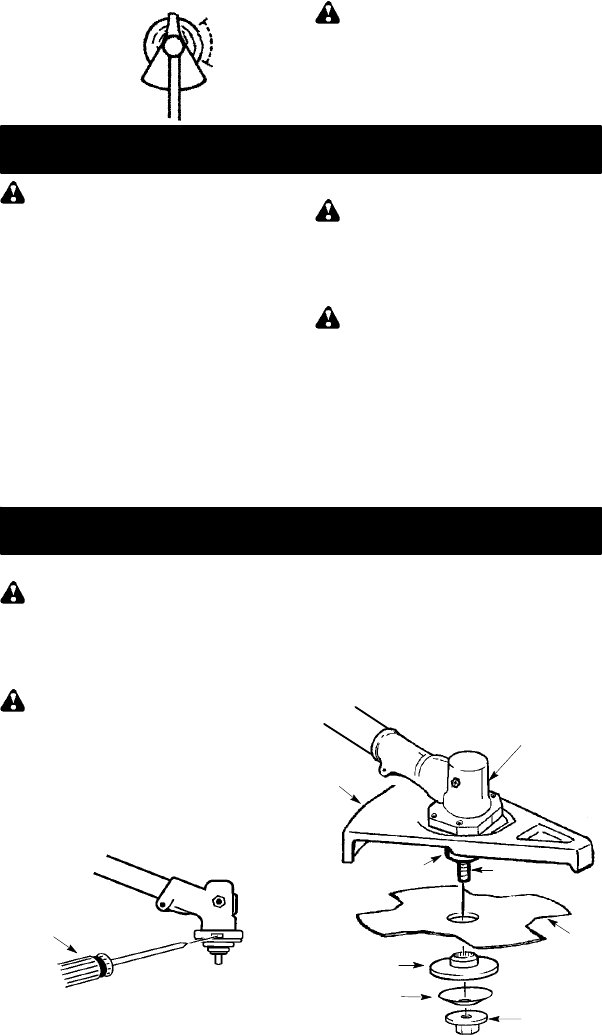

1. Toremovetheblade,alignholeinthedust

cup with the hole in the side of the gear-

box by rotating the blade.

2. Insert a small screwdriver into aligned

holes. This will keep the shaft from turn-

ing while loosening the blade nut.

Screwdriver

3. While holdingthe screwdriver inposition,

removeblade nutbyturningclockwiseas

you are facing the nut.

4. Remove both washers and the blade

from the blade shaft. Leave the dust cup

on the gearbox.

5. Installnew blad e andretaining washer o nto

the threaded shaft extending from the gear-

box (blade must be between the dust cup

and the retaining washer). Make sure the

raised part of the retainingwasher is facing

the gearbox, andtheraised areafits intothe

hole in the center of the blade.

Shield

Blade

Retaining

Washer

Dust Cup

Cupped

Washer

Nut

Threaded Shaft

Gearbox