17

MAINTENANCE

WARNING: Disconnect the spark

plug before performing m aintenance except

for carburetor adjustments.

HELPFUL TIP

IMPORT ANT: Have all

repairs other than the rec-

ommended maintenance

described in the instruction

manual performed by an

authorized service dealer.

If any dealer other than an authorized

service dealer performs work on the

product, Poulan PRO may not pay for

repairs under warranty. It is your re-

sponsibility to ma intain and perform

general maintenance.

CHECK FOR LOOS E

FASTENERS AND PARTS

S Spark Plug Boot

S Air Filter

S Housing Screws

S Assist Handle Screw

S Debris Shield

CHECK FOR DAMA GED OR

WORN PARTS

Contact an authorized service dealer fo r re-

placement of damaged or worn parts.

S ON/STOP Switch -- Ensure ON/STOP

switch functions properly by pushing and

releasing the switch. Make sure engine

stops. Wait 5 seconds before attempting to

restart unit to allow switch to reset. Restart

engine and continue.

S Fuel tank -- Discontinue use of unit if fuel

tank shows signs of damage or leaks.

S Oil tank -- Discontinue use of unit if oil tank

shows signs of dam age or leaks.

S Debris shield--Discontinueuse ofunitifde-

bris shield is damaged.

INSPECT AND CLEANUNIT AND LA-

BELS

S After each use, inspect complete unit for

loose o rdamagedparts. Cleanthe unitand

labels using adamp cloth with a milddeter-

gent.

S Wipe off unit with a clean dry cloth.

CHECK CHAIN TENSION

WARNING: Wear protective gloves

when handlingchain. Thechain is sharp and

can cutyoueven whenitis notmoving. M ake

chain adjustments with lower end supported.

Chain tension is very important. Chains

stretchduringuse. Thisis especially truedur-

ingthefirst fewtimes youuseyourpruner . Al-

ways check chain tension each time you use

and refuel your unit.

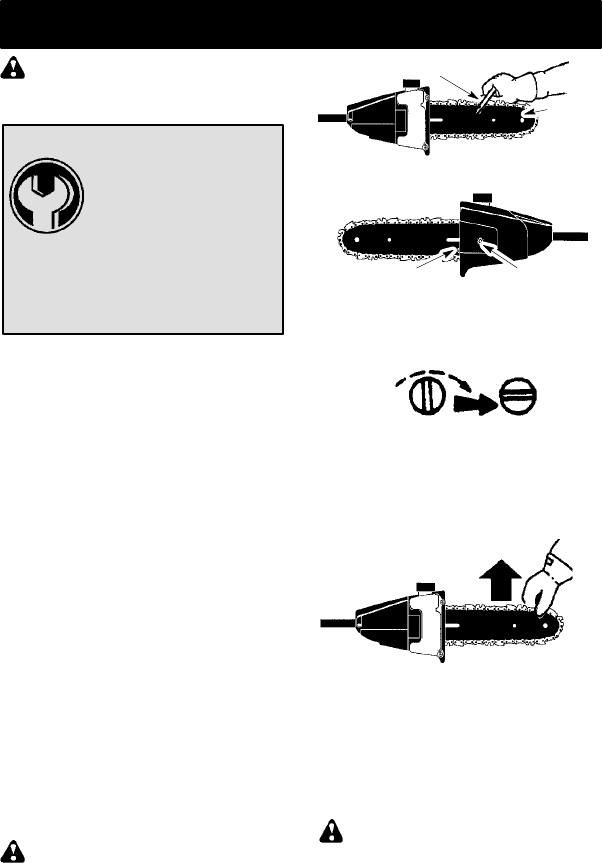

1. Use the screwdriver end of the chain ad-

justment tool (bar tool) to move chain

around guide bar to ensure kinks do not

exist. The chain should rotate freely.

Chain Adjustment Tool

Guide

Bar

2. Loo senbar clampnut untilit is fingertight

against the bar clamp.

Bar clamp nut

Adjusting Screw

3. Turn adjusting screw clockwise until

chain solidlycontacts bottomofguidebar

rail. Then, turn adjusting screw an addi-

tional 1 /4 turn.

Adjusting Screw -- 1/4 Turn

4. Using bar tool, roll chain around guide bar

to ensure all links are in bar g roove.

5. Lift up tip of guide bar to check for sag.

Release tipof guide bar,then turnadjust-

ingscrew1/4turnclockwise.Repeatuntil

sag does not exist.

6. While lifting tip of guide bar, tighten bar

clamp nut securely with the bar tool.

7. Use thescrewdriver endof thebar toolto

move chain around guide bar.

8. If chain does not rotate, it is too tight.

Slightly loosen bar clamp nut and loosen

chain by turning the adjusting screw 1/4

turn counterclockwise. Retighten bar

clamp nut.

9. If chain is too loose, it will sag below the

guide bar and needs to be tightened fol-

lowing above procedure.

WARNING: DO NOT operate the

pruner if the chain is loose. If thepruner is oper-

ated with a loose chain, the chain could jump off

the guide bar and result in serious injury .

CHECK CHAIN SHARPNESS

Asharp chainmakeswoodchips.A dullchain

makes a sawdust powder and cuts slowly.

See CHAIN SHARPENING i n the SERVICE

AND ADJUS T M ENT S sectio n .

CLEAN AIR FILTER

A dirty air filter decreases engine perform-

ance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.