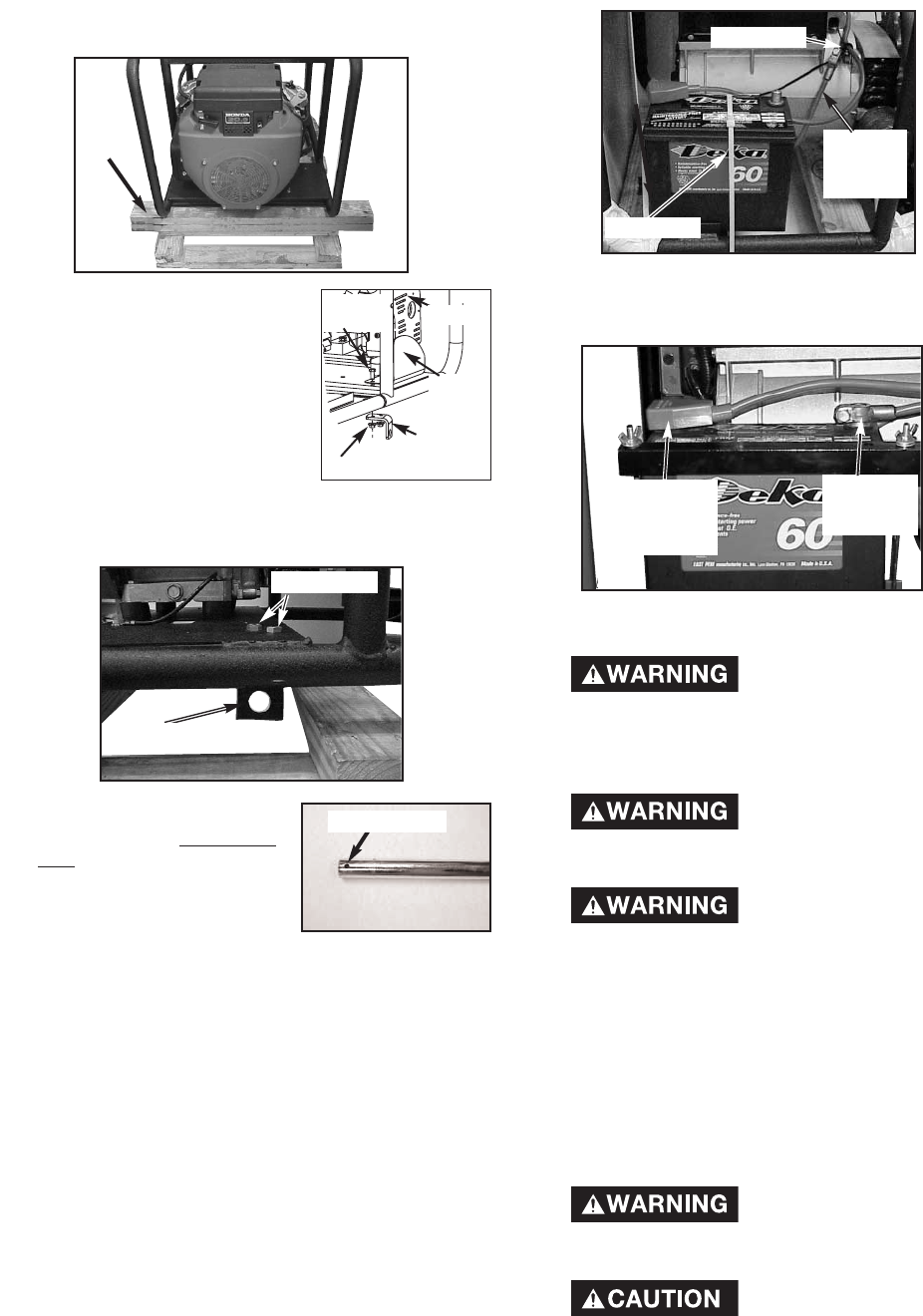

2. Connect black negative cable to negative (-) battery

post. Tighten securely. NOTE: Make sure rubber boot is

covering positive (+) battery terminal.

NOTE: If battery needs to be charged, follow these

instructions.

When charging the battery,

do not smoke. Keep away

from any sparks. The fumes from the battery

acid can cause an explosion. To prevent

explosive fumes from accumulating do not

charge in an enclosed area.

Sulfuric acid is a

flammable and explosive

chemical that is harmful to the skin, eyes, and

clothing.

To prevent sparks,

disconnect the black

battery cable from the negative (-) terminal

before disconnecting the red positive cable.

1. Remove black negative battery cable from the battery.

2. Remove red positive battery cable from the battery.

3. Use a portable 12 volt battery charger, if needed, to

bring battery to full charge (12.6 at 70ºF.). Refer to the

battery charger’s operator’s manual for the correct

procedure. If a battery charger is not available, have an

authorized service center charge the battery.

4. Connect the battery cables.

To Prevent sparks connect

the red (positive) cable to

the positive (+) terminal before connecting the

black negative cable.

When transporting unit over

extremely rough terrain by

vehicle the battery should be secured.

BATTERY INSTALLATION

The generator is equipped with a maintenance free battery.

1. For packaging purposes the black negative battery cable

and battery were secured with wire ties. Cut these wire

ties.

11 — ENG

Positive

Battery

Cable with

rubber boot

Negative

Battery

Cable

6. Lift other end of generator and place two 2x4s between

generator and pallet as shown.

7. On the muffler side of the engine,

remove cap screws and flange

nuts holding the heat shield to the

frame. Reassemble cap screws,

heat shield, wheel bracket, and

flange nuts and as shown. Tighten

securely.

8. On other side, assemble wheel

bracket using cap screws and

flange nuts supplied. Tighten securely.

NOTE: Brackets are placed under frame with hole facing

outward.

9. Using a hammer tap axle cap

onto end of axle, without the

hole.

10. Slide wheel onto axle with

valve stem to the outside.

11. Slide spacer onto axle against

wheel.

12. Slide axle through axle brackets. NOTE: The pallet will

need to be removed before the wheel can be

assembled.

13. Lift generator and slide pallet and 2x4s out. NOTE:

Generator will tilt.

14. Lift generator and slide spacer, then wheel (with valve

stem to the outside) onto axle.

15. Slide flat steel washer onto axle against wheel.

16. Secure with cotter pin.

2x4

Cap screws

Wheel Bracket

Hole in Axle

Negative

Battery

Cable

Wire Tie

Wire Tie

Muffler

Heat

Shield

Cap

Screw

Wheel

Bracket

Flange Nuts