MegaTherm Commercial Pool Heating Boiler

Page 7

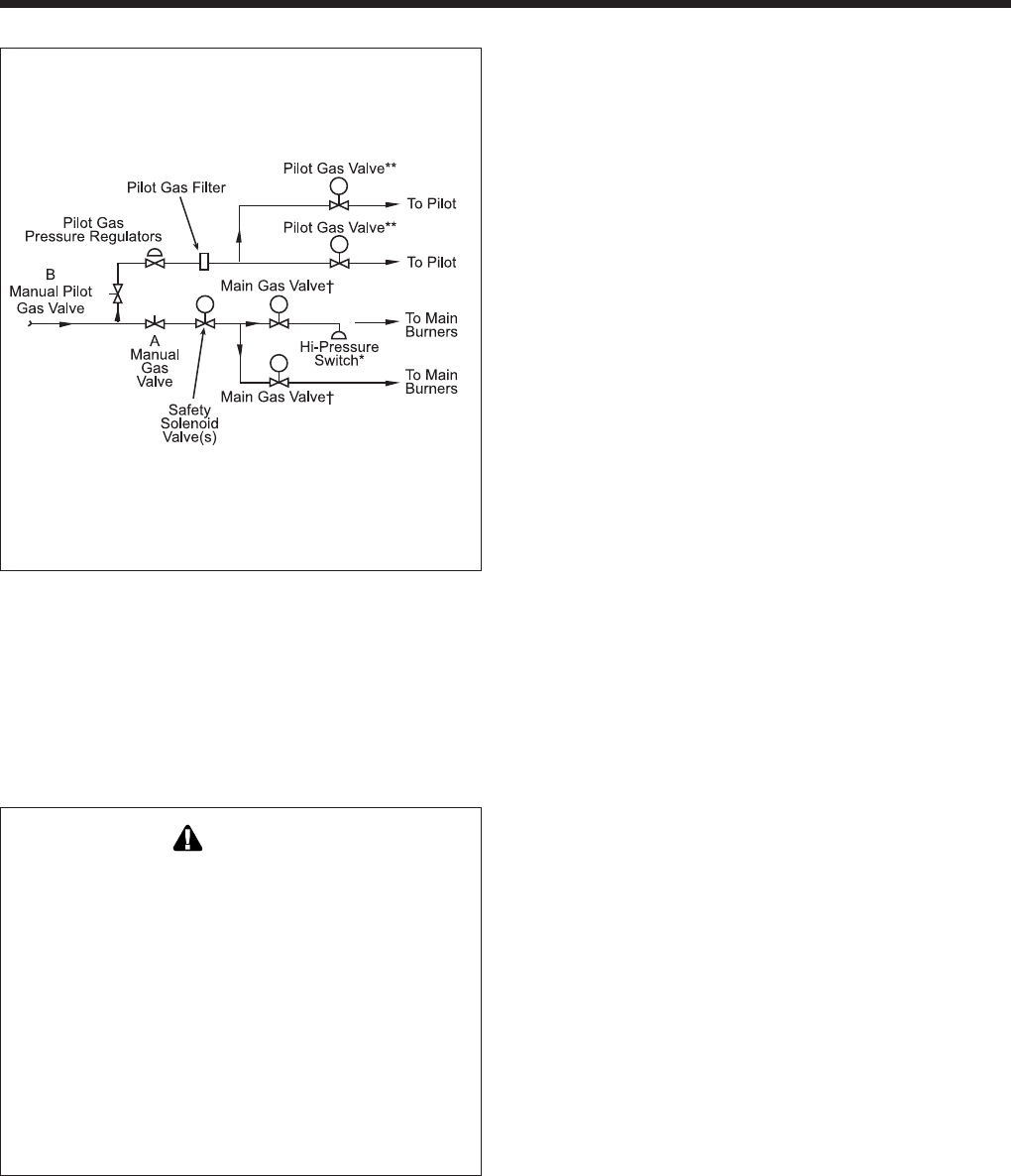

Arrangement of gas train components for on-off

firing are shown schematically in the Gas Piping

Diagram (see Figure 6).

2F. Electrical Wiring

WARNING

The boiler must be electrically grounded in

accordance with the most recent edition of the

National Electrical Code, ANSI/NFPA 70, and

in Canada, follow Canadian Electrical Code

CSA C22.1. Do not rely on the gas or water

piping to ground the metal parts of the boiler.

Frequently, plastic pipe or dielectric unions

isolate the boiler electrically. Service and

maintenance personnel who work on or around

the unit may be standing on wet floors and

could be electrocuted by a poorly grounded

boiler.

1. Check boiler wiring and pump for correct volt

age, frequency and phase. If the pump circuit is

other than 115V, check to see that the boiler is

provided with an appropriate transformer.

2. Wire the boiler and pump exactly as shown in

the wiring diagram supplied with the boiler.

3. The pump and boiler must be electrically

interlocked so the boiler cannot come on unless

the pump is running.

4. All field installed electrical safety devices and all

field installed devices (draft switches, relays,

timers, etc.) can be connected to the boiler

wiring at points shown in the wiring diagram

designated “Field Interlock.”

5. Auxiliary Time Clock Wiring. If a time clock is

used to control the filter pump operation, a

separate switch must be used to shut off the

boiler at least 15 minutes before the filter pump

is shut off. Wire the separate switch (sometimes

called a “Fireman Switch”) at the points shown

on the internal wiring diagram as “Field

Interlock.”

2G. Piping of System to Boiler

1. Be sure to provide gate valves at the inlet and

outlet to the boiler so it can be readily isolated

for service.

2. The pressure relief valve must be installed in the

tapped opening provided, or on a “Tee” fitting

when provided, in the boiler outlet header with

its outlet piped to a drain or floor sink. Special

attention must be given to relief valve settings in

installations where the boiler is located on the

ground floor of a tall building. The static

pressure of the system is elevated, and could

cause the relief valve to leak. Where no special

setting of the relief valve is ordered, the factory

will furnish a 75 psi setting. Never reduce the

relief valve opening. If necessary, install the

relief valve in a Tee immediately past the boiler

outlet. The weight of all water and gas piping

should be supported by suitable hangers or floor

stands. Check piping diagrams with local

applicable plumbing, heating and building

safety codes.

2H. General Water Piping

1. Plastic fittings, grids, or other elements of the

filter system are subject to damage by the

momentary “back syphoning” of hot water when

the pump stops. To prevent this backflow, install

a swinging gate check valve in the piping

between the filter and the boiler.

2. No Hartford Loop is required for anti-syphon

protection.

3. No water flow adjustments are required except

when a manual bypass valve is installed.

4. Do not install any valve or other variable

restriction in the return piping between the boiler

outlet and the pool.

5. The outlet pipe is carrying a large volume of

water which has bypassed the boiler combined

with a small volume of very hot water.

Note:

Main Gas Valves Incorporate

Gas Pressure Regulators

* Standard on sizes 3050-5000 (AGA models).

** Sizes 2000 & 2450 use one pilot gas valve.

† Sizes 2000, 2450 & 3050.

Figure 6. Gas Piping Diagram.