USER MANUAL

6 33014815(1)2005-07 A

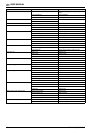

MACHINE DESCRIPTION

Standard machine description

(See Fig. F)

1. Seat

2. Steering wheel

3. Frame

4. Bumpers

5. Hopper hood

6. Hopper

7. Right side lid

8. Seat supporting hood

9. Left side lid

10. Engine hood

11. Right side broom

12. Rear axle

Description of the machine with cab

(See Fig. G)

1. Seat

2. Steering wheel

3. Frame

4. Bumpers

5. Hopper hood

6. Hopper

7. Right side lid

8. Seat supporting hood

9. Left side lid

10. Engine hood

11. Right side broom

12. Rear axle

13. Cab

Frame

Rigid, composite supporting frame on rectangular plan,

consisting of electrically welded steel plates.

The mechanical components of the machine are suitably

sized, according to a 1.4÷1.5 factor, to withstand the dynamic

stress due to the machine operation (supporting frame, hubs,

axles, hopper supporting and lifting system, etc.).

Hopper

The hopper is fitted on the front side of the machine and

connected to the frame by means of a hinge.

A hydraulic cylinder lifts and overturns the hopper when the

waste is to be dumped at a height. The lower part has a

hinged skirt, operated by a hydraulic cylinder, which closes

the hopper while the waste is being dumped. The front side

has two fans operated by a motor. These fans create a

vacuum inside the hopper and in the main broom

compartment. Inside it, there is a polyester closed pocket filter

connected to an electric filter shaker.

On the front right side there is a side broom whose rotation is

operated by a hydraulic motor, while its lifting and lowering

are operated by a hydraulic cylinder.

It is possible to install a side broom on the left side as well and

a third broom for corner cleaning.

Main broom

It consists of a sweeping roller whose rotation is operated by

a hydraulic motor and whose lifting and lowering are operated

by a hydraulic cylinder. It is automatically adjusted by the

self-levelling device.

Engine

The engine, a diesel Lombardini LDW 1003, drives the

hydraulic system pumps.

Front wheels

– Pneumatic wheels

– Superelastic wheels

– They are independent, fastened to the frame by means

of a hub with built-in brake drum. The brakes are

hydraulic. The parking brake is mechanical.

Rear wheels

– Pneumatic wheels

– Superelastic wheels

– The rear axle is driving and steering. The steering is

operated by a hydraulic cylinder connected to the power

steering. A hydrostatic variable delivery pump with

servoassisted control supplies a drive hydraulic motor

for forward and reverse gear.

Dashboard

Fitted on the upper part of the frame and under the steering

wheel, the dashboard houses the machine warning lights and

instrumentation.

Joystick

This is a new system, fitted on sweepers for the first time, by

means of which all the controls are grouped together in a

single lever. The push-button switches located on the joystick

perform all of the machine operational functions.

Hydraulic system

In the first circuit a variable delivery pump feeds the drive

hydraulic motor (rear wheel). The forward and reverse drive

are adjusted by a hydraulic assist operated by a pedal.

In the second circuit a gear pump feeds the power steering

and a distributor which controls: the hopper lifting cylinder, the

side broom lifting and rotation cylinder, the skirt opening and

closing cylinder; the power steering controls the steering

cylinder.

In the third circuit the gear pump feeds a distributor which

controls the main broom lifting/lowering and rotation cylinder

and the fan hydraulic motor rotation.

All circuits are protected by suction filters and safety valves.

Electrical system

12 V electrical system. The circuits are protected by lamellar

fuses housed in a relevant fuse box.