an automatic-start, two-cycle, engine-driven generator, and

include the shutdown and alarm points recommended in NFPA-

110-1988 “Emergency and Standby Generator Systems” for

Level 1 installations. These controllers also meet or exceed the

minimum requirements of NFPA-99-1990 “Health Care

Facilities” and with the addition of a Low Water Level alarm,

the Canadian standard CAN/CSA-C282-M89 “Emergency

Electrical Power Supply for Buildings”. The suffix numbers -12

and -24 indicate the engine starting battery voltage.

3-1.2.1 The A901-2 series control includes an “Air Damper

Closed” light and “Overspeed Relay” to trip the air shut-off

solenoid on overspeed of a two-cycle engine.

3-1.3 A902-12 and A902-24: These models are designed for an

automatic-start, four-cycle, engine-driven generator, and include

the shutdown and alarm points recommended in NFPA-110-

1988 “Emergency and Standby Generator Systems” for Level 2

installations. The suffix numbers -12 and -24 indicate the

engine starting battery voltage.

3-1.4 A902-2-12 and A902-2-24: These models are designed

for an automatic-start, two-cycle, engine-driven generator, and

include the shutdown and alarm points recommended in NFPA-

110-1988 “Emergency and Standby Generator Systems” for

Level 2 installations. The suffix numbers -12 and -24 indicate

the engine starting battery voltage.

3-1.4.1 The A902-2 series control includes an “Air Damper

Closed” light and “Overspeed Relay” to trip the air shut-off

solenoid on overspeed of a two-cycle engine.

3-1.5 A903-12 and A903-24: These models are designed for an

automatic-start, four-cycle, engine-driven generator, and include

the shutdown and alarm points recommended in NFPA-110-

1988 “Emergency and Standby Generator Systems” for Level 2

installations plus seven unlabeled alarms that the user may

specify and an “Alarm Silence Switch”. The suffix numbers -12

and -24 indicate the engine starting battery voltage.

3-1.6 A903-2-12 and A903-2-24: These models are designed for

an automatic-start, two-cycle, engine driven generator, and

include the shutdown and alarm points recommended in NFPA-

110-1988 “Emergency and Standby Generator Systems” for

Level 2 installations plus seven unlabeled alarms that the user

may specify and an “Alarm Silence Switch”. The suffix numbers

-12 and -24 indicate the engine starting battery voltage.

3-1.6.1 The A903-2 series control includes an “Air Damper

Closed” light and “Overspeed Relay” to trip the air shut-off

solenoid on overspeed of a two-cycle engine.

3-1.7 Table 3-1.7 illustrates the alarm and shutdown require-

ments of NFPA-110, NFPA99 and CAN/CSA-C282-M89 and

compares the features of the A900 series controls to those

requirements.

3-2 A901.

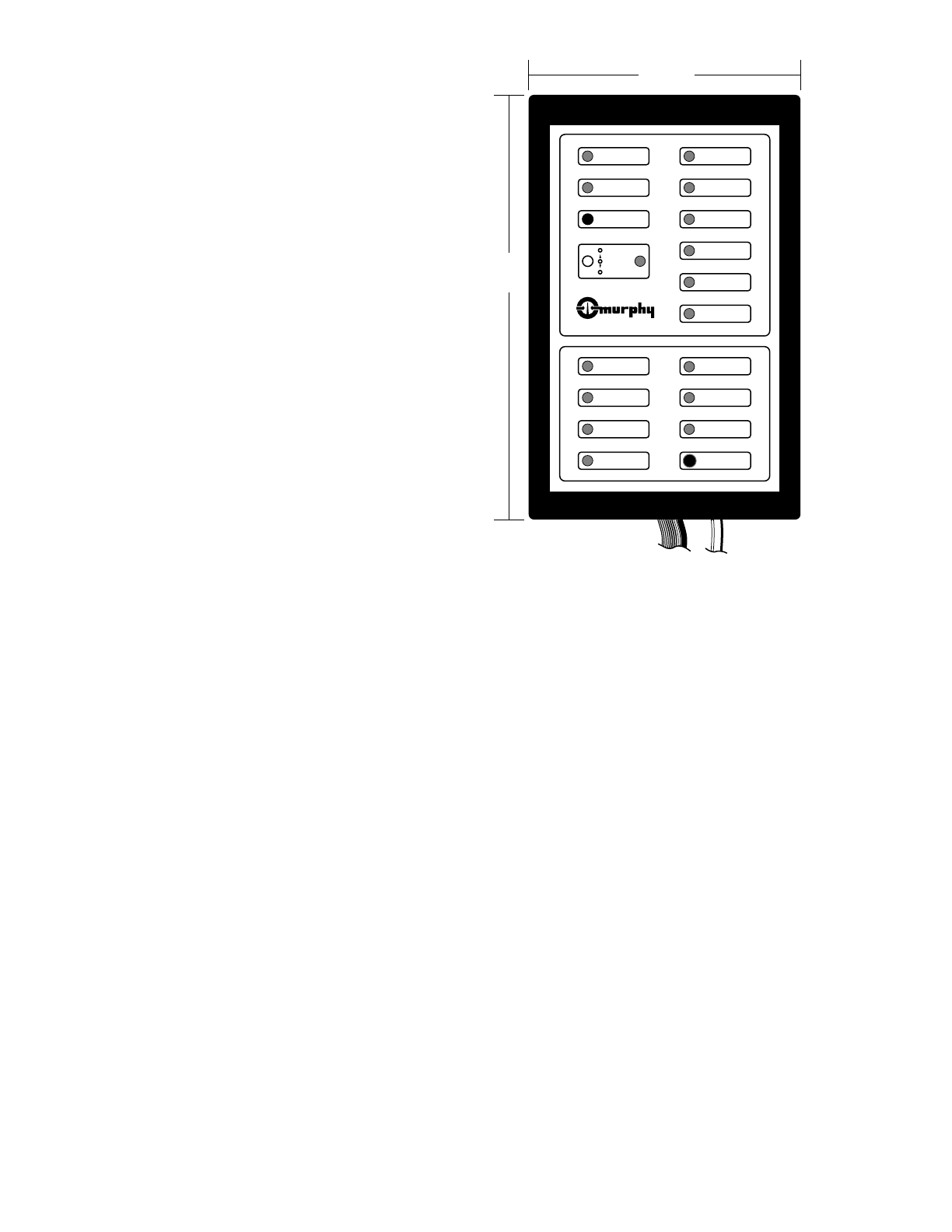

3-2.1 Control / Display Module. The Control / Display Module,

figure 3-2.1, includes the control and test switches, the solid state

logic elements, shutdown and alarm TATTLETALE

®

lights that

make up the generator engine control for a four-cycle engine.

3-2.1.1 Mode Selector Switch, OFF-AUTO-TEST:

(a) OFF; turns off the control system and resets any shutdown

circuits.

(b) AUTO; turns on the engine controls and shutdown circuits.

System is on standby waiting for a contact closure to start

engine.

(c) TEST; turns on the engine controls and shutdown circuits.

A start signal is applied to the automatic control and the

engine start sequence begins.

3-2.1.2 Lamp Test Pushbutton: Tests the lights on the A901

module.

3-2.1.3 Alarm Silence Pushbutton: Turns off any audible alarm

that is connected to the Local or Remote Audible Alarm Relays.

The indicating light will remain on as long as the condition

exists. If the Alarm Silence pushbutton is not operated, the

audible alarm will turn off when the alarm contact clears.

3-2.1.4 The A901 SELECTRONIC

®

Control Module includes

the following engine control features:

(a) Cycle crank circuit; will crank the engine for 15 seconds

then rest for 15 seconds until the engine starts. The

crank/rest time can be selected for either 10, 15, 20, 25 or

30 seconds. If the engine false starts, goes above crank

disconnect speed then drops below that speed, the control

will rest for a fixed 10 second period before cranking again.

(b) Crank Disconnect Speed Switch; this circuit detects

engine speed and terminates cranking when engine speed

rises above the speed switch setting. The speed switch is

adjustable, 25 Hz to 2000 Hz, and is factory set at 1180

Hz. This would be 600 RPM on an engine with 118 teeth

on the flywheel ring gear.

(c) Auxiliary Crank Disconnect Circuit; this circuit, required by

NFPA-110, is provided as a back up for the Crank

Disconnect Speed Switch. It is operated by an external

switch sensing either speed, generator voltage or some other

variable that could be used to terminate cranking. Either

circuit will disconnect the starter when the engine starts.

Low Water

Temperature

AUTO

OFF

TEST

Loss of Speed

Signal

Lamp Test

Water

Temperature

Low Battery

Voltage

Alarm Silence

High Battery

Voltage

Low Fuel

Level

High Water Temp.

PreAlarm

Battery Charger

AC Failure

Switch

Not In AUTO

Low Oil Pressure

PreAlarm

Oil Pressure

Overspeed

Overcrank

6-1/2 in.

(165 mm)

9-3/4 in.

(248 mm)

Figure 3-2.1

2

DISCONTINUED