MQ PS4030 SAW • OPERATION MANUAL — REV. #0 (02/29/08) — PAGE 39

B

A

Certain maintenance operations or machine adjustments

require specialized knowledge and skill. Attempting to

perform maintenance operations or adjustments without

the proper knowledge, skills or training could result in

equipment damage or injury to personnel. If in doubt,

consult your dealer.

WARNINGWARNING

WARNINGWARNING

WARNING

MQ PS4030 SAW — MAINTENANCE

MAINTENANCE

When performing maintenance operations on

the saw or engine, follow all safety messages

and rules for safe operation stated here and

at the beginning of this manual.

See the engine manufacturer's manual

supplied with your machine for appropriate

maintenance schedule and troubleshooting guide for problems.

Accidental starts can cause severe injury or death!

WARNINGWARNING

WARNINGWARNING

WARNING

ALWAYS place the ON/OFF switch in

the OFF position.

Disconnect negative battery cable

from battery before servicing.

Engine and muffler surfaces can get

HOT! Allow to cool before servicing.

Daily (8-10 Hours)

1. Check fluid levels in engine and reservoir; fill as necessary.

2. Visually inspect for wear and damage.

3. Visually inspect for engine leaks.

4. Check or replace the engine air filters as necessary.

5. Check operation of Emergency Stop Button.

Monthly (125-150 Hours)

1. Change Hydraulic oil and filter. (First 125 hours, then every

250 hours.)

2. Change Engine oil and filter.

Yearly (500-600 Hours)

1. Replace fuel filter cartridge, v-belt, and intake air cleaner.

2. Check fuel lines for leakage.

3. Check battery cables and connectors.

4. Check engine monitoring and warning system.

Air Cleaners (Daily)

While the air filters should be checked daily and replaced when

necessary, there is no need to "over-service" the air filters. That

is, they require no cleaning and do not require the use of oil. If

the primary filter becomes clogged, simply replace it.

The saw utilizes both a primary air filter and a safety air filter,

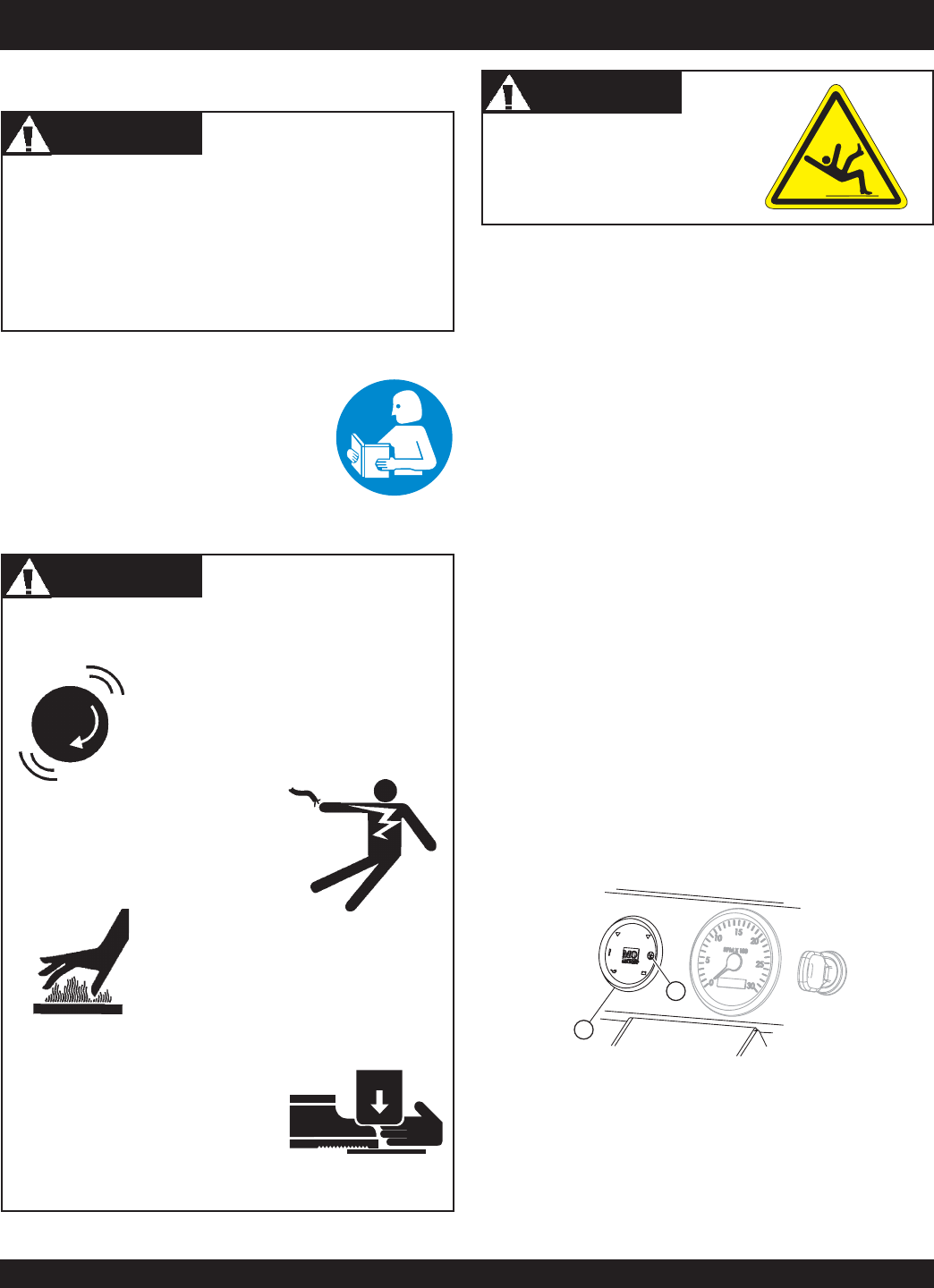

(Figure 38). The air filter restriction light, (Item A, Figure 37) on

the engine status indicator (Item B, Figure 37), will illuminate

when the filter is plugged.

Avoid slips and falls!

Clean up all engine oil, hydraulic

oil, and diesel fuel spills

immediately.

CAUTIONCAUTION

CAUTIONCAUTION

CAUTION

ALWAYS ensure saw is

SECURELY placed on appropriate

blocks or jackstands when

performing maintenance requiring

the saw to be elevated.

Figure 37. Air Filter Restriction Light

Empty the dust discharge valve daily and clean the discharge

slot from time to time. (Figure 38)

Maintenance Schedule